Forward and reverse speed control circuit can be integrated with a brake function

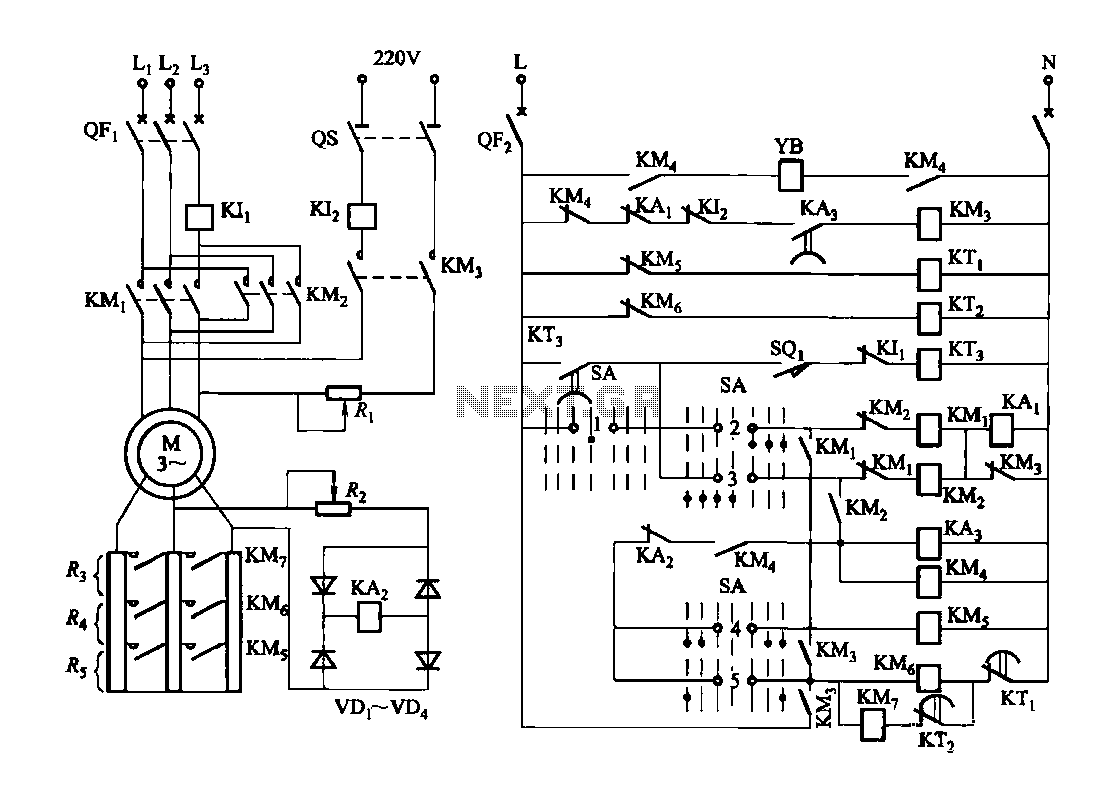

Figure 3173 illustrates a control circuit for a wound rotor induction motor that enables mechanical braking, dynamic braking, and reverse braking functions. The circuit includes various components such as relays, contactors, and time relays to manage the motor's speed in both positive and negative directions. Key components include the KI overcurrent relay, KI2 overcurrent relay, KMi for positive turn contacts, KM2 for reverse contactors, KMa for the powered brake contactor, KM4 for the braking contactor, KMs for the trans pick brake contactor, KM6 and KM7 for acceleration contacts, YB for the brake electromagnet, KAi for the brake relay, KAz for the reverse brake relay, KA3 for the powered brake relay, and KTi, KT2, and KT3 for the time relays. The reverse brake relay KA3 is activated during reverse braking, and the motor slip is monitored. When the motor's speed drops close to zero, the relay is released. A high coefficient DC relay is required for proper operation. The KI relay activates in case of mechanical jamming, which occurs due to rapid overcurrent. The dynamic brake relay KAs, functioning as a time relay, controls the dynamic brake contactor KM3, thereby managing energy consumption during motor operation.

The circuit design in Figure 3173 is integral for applications requiring precise motor control in various operational modes. The inclusion of multiple relays and contactors allows for robust functionality, ensuring that the motor can efficiently switch between mechanical braking, dynamic braking, and reverse operations.

The KI and KI2 overcurrent relays serve a critical safety function, preventing damage to the motor by detecting excessive current conditions that may arise from mechanical jamming or overload situations. The KMi and KM2 contactors facilitate smooth transitions between forward and reverse operations, allowing for flexible motor control in applications such as conveyors or hoists.

Moreover, the KMa and KM4 contactors are essential for engaging the braking systems, with KMa controlling the powered brake and KM4 managing the braking action. The trans pick brake contactor (KMs) is activated during specific conditions to ensure that the motor can quickly halt its operation when necessary.

The time relays (KTi, KT2, KT3) play a pivotal role in timing the actions of the braking and acceleration processes, ensuring that each operation is executed with precision. The dynamic brake relay (KAs) is particularly noteworthy, as it manages the engagement of the dynamic brake contactor (KM3), allowing for controlled energy dissipation during rapid deceleration, which is crucial for maintaining system stability and performance.

Overall, the circuit's design promotes efficient motor control while safeguarding against potential failures, making it suitable for a wide range of industrial applications requiring reliable and responsive motor operations.Figure 3173 is a mechanical braking, dynamic braking, reverse braking function wound rotor induction motor speed can be positive and negative control circuit. Figure, KI, to st all relay (actually overcurrent relay); KI2 overcurrent relay; KMi positive turn contacts; KM2 to reverse contactors; KMa powered brake contactor; KM4 braking contactor; KMs trans pick brake contactor; KM6, KM7 to accelerate contacts; YB brake electromagnet; KAi brake relay; KAz to reverse brake relay; KA3 powered brake relay; KTi, KT2, KT3 the time relay. Wherein the reverse brake relay KA3 is started in reverse braking, the motor slip sa: O when the action, and the turn speed drop close to zero (ie, when s Fl) was released.

Returns must be high coefficient of DC relay. Only action case stall relay KI, in the production of mechanical jamming stall occurs when, due to the rapid emergence of the motor overcurrent. Dynamic brake relay KAs (in essence, a time relay) to control the dynamic brake contactor KM3 action into a step motor control energy consumption rubidium move.

The circuit design in Figure 3173 is integral for applications requiring precise motor control in various operational modes. The inclusion of multiple relays and contactors allows for robust functionality, ensuring that the motor can efficiently switch between mechanical braking, dynamic braking, and reverse operations.

The KI and KI2 overcurrent relays serve a critical safety function, preventing damage to the motor by detecting excessive current conditions that may arise from mechanical jamming or overload situations. The KMi and KM2 contactors facilitate smooth transitions between forward and reverse operations, allowing for flexible motor control in applications such as conveyors or hoists.

Moreover, the KMa and KM4 contactors are essential for engaging the braking systems, with KMa controlling the powered brake and KM4 managing the braking action. The trans pick brake contactor (KMs) is activated during specific conditions to ensure that the motor can quickly halt its operation when necessary.

The time relays (KTi, KT2, KT3) play a pivotal role in timing the actions of the braking and acceleration processes, ensuring that each operation is executed with precision. The dynamic brake relay (KAs) is particularly noteworthy, as it manages the engagement of the dynamic brake contactor (KM3), allowing for controlled energy dissipation during rapid deceleration, which is crucial for maintaining system stability and performance.

Overall, the circuit's design promotes efficient motor control while safeguarding against potential failures, making it suitable for a wide range of industrial applications requiring reliable and responsive motor operations.Figure 3173 is a mechanical braking, dynamic braking, reverse braking function wound rotor induction motor speed can be positive and negative control circuit. Figure, KI, to st all relay (actually overcurrent relay); KI2 overcurrent relay; KMi positive turn contacts; KM2 to reverse contactors; KMa powered brake contactor; KM4 braking contactor; KMs trans pick brake contactor; KM6, KM7 to accelerate contacts; YB brake electromagnet; KAi brake relay; KAz to reverse brake relay; KA3 powered brake relay; KTi, KT2, KT3 the time relay. Wherein the reverse brake relay KA3 is started in reverse braking, the motor slip sa: O when the action, and the turn speed drop close to zero (ie, when s Fl) was released.

Returns must be high coefficient of DC relay. Only action case stall relay KI, in the production of mechanical jamming stall occurs when, due to the rapid emergence of the motor overcurrent. Dynamic brake relay KAs (in essence, a time relay) to control the dynamic brake contactor KM3 action into a step motor control energy consumption rubidium move.