Stepper Motor Controller

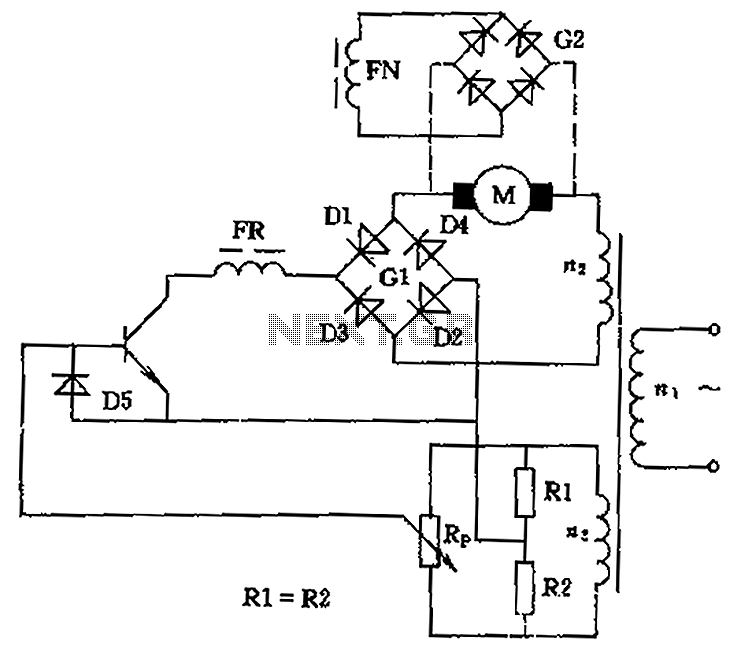

A stepper motor provides a simple, low-cost, and precise method for position control. It can be driven by a circuit that is mounted near the motor and controlled by a microcontroller.

Stepper motors are widely utilized in applications requiring precise control of movement and positioning. They operate by dividing a full rotation into a series of discrete steps, allowing for fine control over angular position. The motor's ability to hold its position without the need for continuous power makes it ideal for applications such as 3D printers, CNC machines, and robotics.

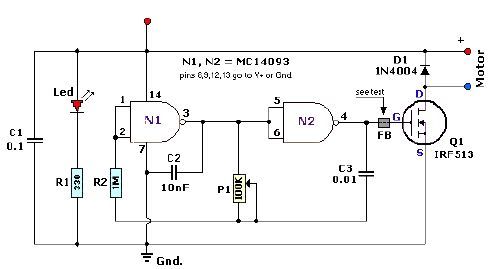

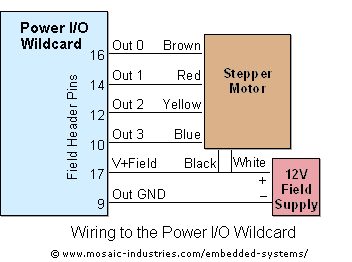

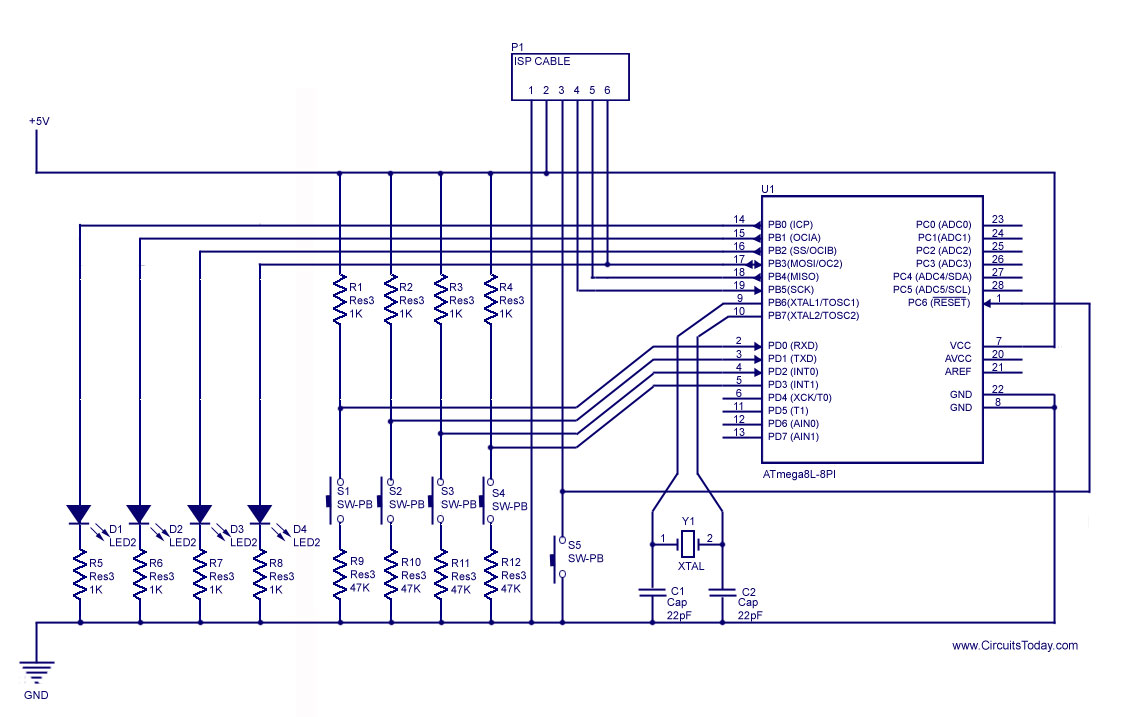

The driving circuit for a stepper motor typically includes a microcontroller, which generates the necessary control signals to drive the motor. The microcontroller sends pulses to a driver circuit that powers the motor coils in a specific sequence, causing the rotor to move in precise increments. This sequence is often referred to as "stepping," and the number of steps per revolution is a critical parameter that defines the motor's resolution.

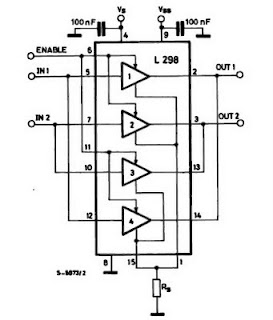

In a typical configuration, the stepper motor will have multiple coils (phases), and the control circuit will energize these coils in a specific order to achieve the desired rotation direction and speed. The use of H-bridge configurations in the driver circuit allows for bidirectional control of the motor, enabling it to rotate clockwise or counterclockwise based on the input signals.

For enhanced performance, microstepping techniques can be employed, which involve controlling the current through the motor coils to create intermediate steps. This results in smoother motion and increased resolution, making it suitable for applications that require high precision.

In summary, the combination of a stepper motor with an appropriately designed driving circuit offers an effective solution for applications demanding accurate position control, with the added benefits of low cost and simplicity in implementation.Stepper motor gives a simple, low cost, and accurate position control. Stepper motor can be driven by circuit mounted close to the motor, and controlled by a. 🔗 External reference

Stepper motors are widely utilized in applications requiring precise control of movement and positioning. They operate by dividing a full rotation into a series of discrete steps, allowing for fine control over angular position. The motor's ability to hold its position without the need for continuous power makes it ideal for applications such as 3D printers, CNC machines, and robotics.

The driving circuit for a stepper motor typically includes a microcontroller, which generates the necessary control signals to drive the motor. The microcontroller sends pulses to a driver circuit that powers the motor coils in a specific sequence, causing the rotor to move in precise increments. This sequence is often referred to as "stepping," and the number of steps per revolution is a critical parameter that defines the motor's resolution.

In a typical configuration, the stepper motor will have multiple coils (phases), and the control circuit will energize these coils in a specific order to achieve the desired rotation direction and speed. The use of H-bridge configurations in the driver circuit allows for bidirectional control of the motor, enabling it to rotate clockwise or counterclockwise based on the input signals.

For enhanced performance, microstepping techniques can be employed, which involve controlling the current through the motor coils to create intermediate steps. This results in smoother motion and increased resolution, making it suitable for applications that require high precision.

In summary, the combination of a stepper motor with an appropriately designed driving circuit offers an effective solution for applications demanding accurate position control, with the added benefits of low cost and simplicity in implementation.Stepper motor gives a simple, low cost, and accurate position control. Stepper motor can be driven by circuit mounted close to the motor, and controlled by a. 🔗 External reference