testing ddl s circuit

A guide will be posted on how to test a DDL circuit before integrating the LD. The process aims to ensure clarity and accuracy throughout.

To properly test a DDL (Direct Drive Laser) circuit before adding the LD (Laser Diode), several steps must be followed to ensure the circuit functions correctly and safely.

1. **Preparation**: Gather necessary tools including a multimeter, oscilloscope, power supply, and appropriate test loads. Ensure that all components are rated for the specifications of the DDL circuit.

2. **Visual Inspection**: Begin with a thorough visual inspection of the circuit board and components. Look for any signs of damage, such as burnt traces, cracked components, or incorrect solder joints. Ensure that all components are properly placed according to the schematic.

3. **Power Supply Check**: Before applying power, verify that the power supply voltage matches the specifications of the DDL circuit. It is critical to ensure that the polarity is correct to prevent damage.

4. **Initial Testing**: Power the circuit without the LD connected. Measure the voltage at various points in the circuit with a multimeter to ensure that the expected voltages are present. This includes checking the supply voltage and any reference voltages required by the circuit.

5. **Signal Testing**: Use an oscilloscope to analyze the output signal of the circuit. Check for the correct waveform shape and frequency. This step is crucial to confirm that the circuit is generating the appropriate signals to drive the LD once it is connected.

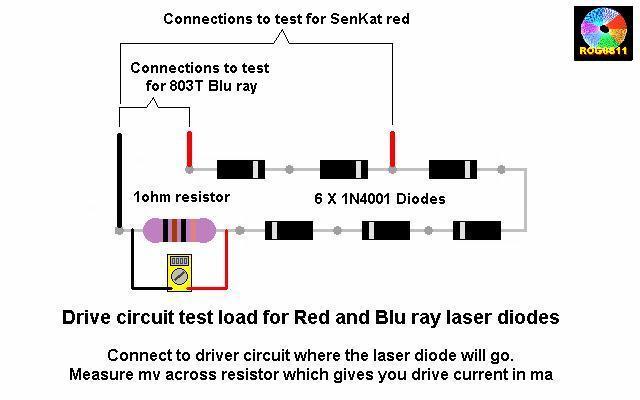

6. **Load Testing**: If the circuit includes a test load, connect it and observe the circuit's behavior under load conditions. Monitor for any fluctuations in voltage or current that may indicate issues within the circuit.

7. **Final Verification**: After all tests have been completed and the circuit has been confirmed to be functioning correctly, it is safe to proceed with integrating the LD. Ensure that the LD is correctly oriented and connected according to the schematic.

By following these steps, the DDL circuit can be effectively tested to ensure reliability and performance prior to the addition of the laser diode. This process helps prevent potential damage to the LD and ensures optimal operation of the entire system.I am about to post a How To on testing DDL`s circuit before adding the LD, I hope it is all pretty clear and with no errors. Those .. 🔗 External reference

To properly test a DDL (Direct Drive Laser) circuit before adding the LD (Laser Diode), several steps must be followed to ensure the circuit functions correctly and safely.

1. **Preparation**: Gather necessary tools including a multimeter, oscilloscope, power supply, and appropriate test loads. Ensure that all components are rated for the specifications of the DDL circuit.

2. **Visual Inspection**: Begin with a thorough visual inspection of the circuit board and components. Look for any signs of damage, such as burnt traces, cracked components, or incorrect solder joints. Ensure that all components are properly placed according to the schematic.

3. **Power Supply Check**: Before applying power, verify that the power supply voltage matches the specifications of the DDL circuit. It is critical to ensure that the polarity is correct to prevent damage.

4. **Initial Testing**: Power the circuit without the LD connected. Measure the voltage at various points in the circuit with a multimeter to ensure that the expected voltages are present. This includes checking the supply voltage and any reference voltages required by the circuit.

5. **Signal Testing**: Use an oscilloscope to analyze the output signal of the circuit. Check for the correct waveform shape and frequency. This step is crucial to confirm that the circuit is generating the appropriate signals to drive the LD once it is connected.

6. **Load Testing**: If the circuit includes a test load, connect it and observe the circuit's behavior under load conditions. Monitor for any fluctuations in voltage or current that may indicate issues within the circuit.

7. **Final Verification**: After all tests have been completed and the circuit has been confirmed to be functioning correctly, it is safe to proceed with integrating the LD. Ensure that the LD is correctly oriented and connected according to the schematic.

By following these steps, the DDL circuit can be effectively tested to ensure reliability and performance prior to the addition of the laser diode. This process helps prevent potential damage to the LD and ensures optimal operation of the entire system.I am about to post a How To on testing DDL`s circuit before adding the LD, I hope it is all pretty clear and with no errors. Those .. 🔗 External reference