the water level control system design of the one-chip computer

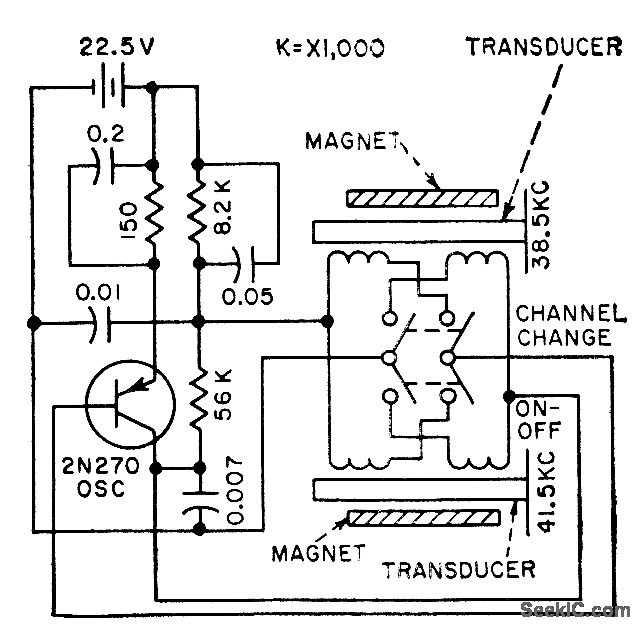

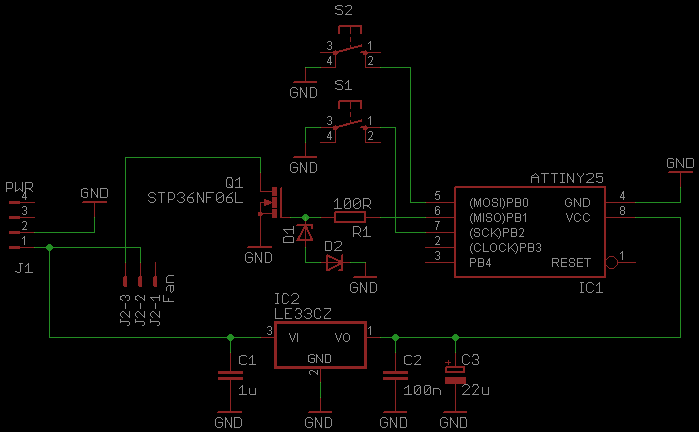

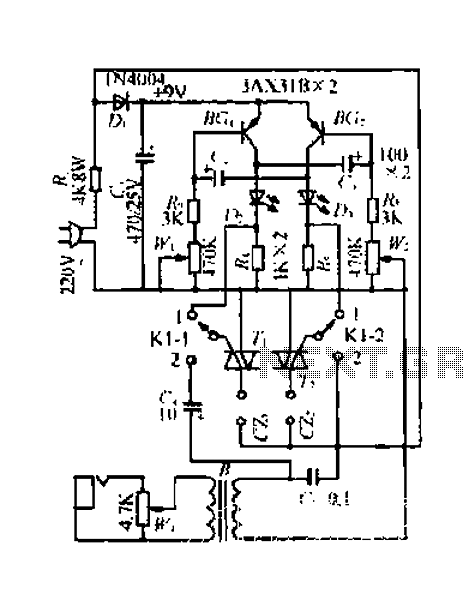

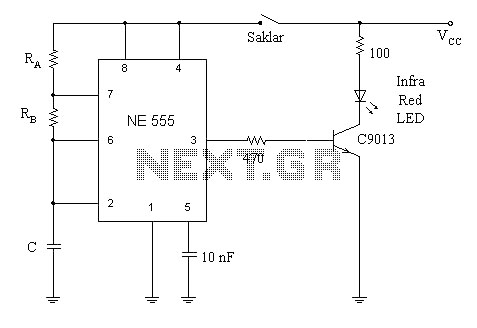

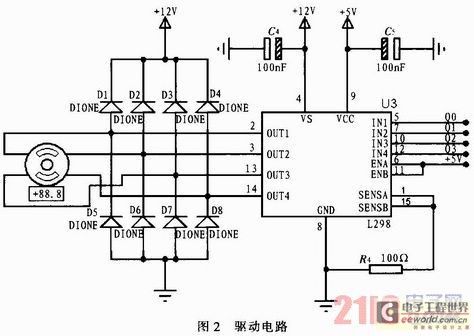

In the production field, automatic detection of water levels and control is a critical technology for industrial process control, significantly enhancing the level of automation in these processes. In everyday life, water supply has traditionally been managed manually, which has led to resource losses and increased attention to water resource management. Currently, water level control systems are widely used in water supply systems, employing various methods such as mechanical control, logic circuit control, electromechanical control, and sensor-based control. However, traditional control methods often suffer from low accuracy, high energy consumption, and an inability to provide continuous control or track water levels effectively. This thesis proposes a more convenient and accurate water level control system, primarily integrating a microcontroller with minimal system circuitry, a water level detection circuit, a stepper motor driving circuit, a water level display circuit, and a water pump driving circuit, alongside software design. The system block diagram is depicted in Fig. 1. The microcontroller and control module, as shown in Fig. 1, form the key components of the system, with a keyboard and display unit facilitating human-computer interaction. Parameters and states are input via the keyboard into the microcontroller and displayed on the unit. When the water level in the tank drops, a probe moves downward, and a simple algorithm allows for real-time display of the water level on the display unit. The microcontroller generates control impulses for the stepper motor, which is monitored and processed to display the current water level on the terminal LCD. The control device utilizes the AT89S52 microcontroller, known for its strong arithmetic capabilities and flexible programming options, enabling various algorithms and logic control through software programming. The FPGA is noted for its fewer chip pins, ease of hardware implementation, low power consumption, compact size, and cost-effectiveness due to mature technology. The primary design objective is to control the rotational speed of the electric motor, which uses a four-wire, quarter-phase stepper motor. Consequently, a dedicated motor driver module, the L298N chip, is selected due to its simple circuit design, strong anti-jamming capability, and good reliability. The schematic circuit diagrams are illustrated in Fig. 2. Traditional water level measurement techniques typically involve pressure sensors interfaced with an ADC, which complicates operations and lacks sufficient precision. Alternatively, contact-type methods utilize several metal bars positioned at different levels in the tank to detect water levels based on conductivity, which is simpler but does not allow for serial water level control. This design employs a mechanically controlled stepper motor with a probe that moves to touch the water, allowing the microcontroller to gather and process data effectively.

The proposed water level control system integrates modern technology to enhance operational efficiency and accuracy in water management. The use of a microcontroller, specifically the AT89S52, allows for sophisticated control algorithms to be implemented, which can adapt to varying conditions and provide real-time feedback. The system's architecture includes a water level detection circuit that continuously monitors the water level and communicates with the microcontroller. The stepper motor, driven by the L298N motor driver, enables precise control of the probe's position, ensuring accurate water level readings.

The use of sensors to detect water levels provides a significant improvement over traditional methods. The microcontroller processes the signals from the sensors and adjusts the motor's operation accordingly, allowing for responsive control of the water supply. This system can be programmed to maintain specific water levels, reducing waste and improving resource management. The display unit provides a user-friendly interface for monitoring and adjusting settings, enhancing user interaction with the system.

Overall, this water level control system represents a significant advancement in automation for both industrial and domestic applications, addressing the challenges of traditional methods while improving efficiency, accuracy, and reliability in water resource management. The integration of modern microcontroller technology and stepper motor control paves the way for future developments in automated water management systems.In the production field, realize the automatic detection of the water level and control a critical technology that is the industrial process control, have important meanings in the automation level which improves industrial process control. In life field, supplied water the way was generally through realizing control manually in the pasted, apt to contribute to the losses that to water

resource, so people pay more and more attention to the question of the water resource now. At present, the water level control system is a water supply system employed extensively, there can be many kinds of implement methods in water level control, such as mechanical control, logic circuit control, electromechanical control, sensor are controlled etc. , but control accuracy exists low in the traditional control mode, energy consumption is great, can`t realize continuous control and characteristic of tracing water level, so a thesis designs the more convenient more accurate water level control system.

Mainly by the intersection of one-chip computer and minimum the intersection of system and circuit, the intersection of water level and detection circuit, the intersection of stepping motor and driving circuit, the intersection of water level and display circuit, the intersection of water pump and driving circuit, software design, etc. system this. Design the system block diagram to be shown as in Fig. 1. The intersection of one-chip computer and control module in the 1 Fig. , for key part of system, keyboard and display unit used for, realize the intersection of human-computer interaction and function, parameter and state that among them will need setting up through the keyboard are input into the one-chip computer, and reveal on the display unit through the control device, when dropping in water level in the water tank, move the probe with dropping, pass the simple algorithm, the water level in the display unit real-time display water tank again too.

The control device of the one-chip computer is used mainly for producing the control impulse of the stepping motor, the step number is gathered and dealt with at present to the stepping motor, and then pass the simple algorithm, reveal the present water level on the terminal station LCD. The choice to the control device adopts AT89S52 as the scheme of system control. AT89S52 one-chip computer arithmetic operation function is strong, the degree of freedom flexible in programming of the software is large, can be realized by programming of software various algorithms and logic control.

As to FPGA, its chip pins are few, in very easy realization of the hardware. And it also has low power dissipation, volume it is small, and cost low grade advantage that technology is ripe. The main purpose to design this time is the rotational speed of the control electric machine, its electrical machinery adopts the four-wire stepping motor of quarter-phase, so the electrical machinery driver module is essential, its scheme determines to adopt the dedicated motor drive chip L298N, the circuit design of chip of this motor drive is simple, antijamming capability is strong, reliability is good.

Their schematic circuit diagrams are shown as in Fig. 2. The traditional water level measures and adopts the pressure capsule, change through AD again, convey to the one-chip computer, operation is complicated, the precision is not high enough, or it is contact-type to adopt and pick up signals, change of the water level of perception of installing several metal bars of different positions in the water tank, utilize the metal and aqueous conductivity collection water level signal directly, operation is simple, but can`t realize the control of the serial water level. Design utilizing the mechanically controlled stepping motor of the one piece this time, hang one to move the probe on the stepping motor, the probe touches water, then the one-chip computer gathers to the si

🔗 External reference

The proposed water level control system integrates modern technology to enhance operational efficiency and accuracy in water management. The use of a microcontroller, specifically the AT89S52, allows for sophisticated control algorithms to be implemented, which can adapt to varying conditions and provide real-time feedback. The system's architecture includes a water level detection circuit that continuously monitors the water level and communicates with the microcontroller. The stepper motor, driven by the L298N motor driver, enables precise control of the probe's position, ensuring accurate water level readings.

The use of sensors to detect water levels provides a significant improvement over traditional methods. The microcontroller processes the signals from the sensors and adjusts the motor's operation accordingly, allowing for responsive control of the water supply. This system can be programmed to maintain specific water levels, reducing waste and improving resource management. The display unit provides a user-friendly interface for monitoring and adjusting settings, enhancing user interaction with the system.

Overall, this water level control system represents a significant advancement in automation for both industrial and domestic applications, addressing the challenges of traditional methods while improving efficiency, accuracy, and reliability in water resource management. The integration of modern microcontroller technology and stepper motor control paves the way for future developments in automated water management systems.In the production field, realize the automatic detection of the water level and control a critical technology that is the industrial process control, have important meanings in the automation level which improves industrial process control. In life field, supplied water the way was generally through realizing control manually in the pasted, apt to contribute to the losses that to water

resource, so people pay more and more attention to the question of the water resource now. At present, the water level control system is a water supply system employed extensively, there can be many kinds of implement methods in water level control, such as mechanical control, logic circuit control, electromechanical control, sensor are controlled etc. , but control accuracy exists low in the traditional control mode, energy consumption is great, can`t realize continuous control and characteristic of tracing water level, so a thesis designs the more convenient more accurate water level control system.

Mainly by the intersection of one-chip computer and minimum the intersection of system and circuit, the intersection of water level and detection circuit, the intersection of stepping motor and driving circuit, the intersection of water level and display circuit, the intersection of water pump and driving circuit, software design, etc. system this. Design the system block diagram to be shown as in Fig. 1. The intersection of one-chip computer and control module in the 1 Fig. , for key part of system, keyboard and display unit used for, realize the intersection of human-computer interaction and function, parameter and state that among them will need setting up through the keyboard are input into the one-chip computer, and reveal on the display unit through the control device, when dropping in water level in the water tank, move the probe with dropping, pass the simple algorithm, the water level in the display unit real-time display water tank again too.

The control device of the one-chip computer is used mainly for producing the control impulse of the stepping motor, the step number is gathered and dealt with at present to the stepping motor, and then pass the simple algorithm, reveal the present water level on the terminal station LCD. The choice to the control device adopts AT89S52 as the scheme of system control. AT89S52 one-chip computer arithmetic operation function is strong, the degree of freedom flexible in programming of the software is large, can be realized by programming of software various algorithms and logic control.

As to FPGA, its chip pins are few, in very easy realization of the hardware. And it also has low power dissipation, volume it is small, and cost low grade advantage that technology is ripe. The main purpose to design this time is the rotational speed of the control electric machine, its electrical machinery adopts the four-wire stepping motor of quarter-phase, so the electrical machinery driver module is essential, its scheme determines to adopt the dedicated motor drive chip L298N, the circuit design of chip of this motor drive is simple, antijamming capability is strong, reliability is good.

Their schematic circuit diagrams are shown as in Fig. 2. The traditional water level measures and adopts the pressure capsule, change through AD again, convey to the one-chip computer, operation is complicated, the precision is not high enough, or it is contact-type to adopt and pick up signals, change of the water level of perception of installing several metal bars of different positions in the water tank, utilize the metal and aqueous conductivity collection water level signal directly, operation is simple, but can`t realize the control of the serial water level. Design utilizing the mechanically controlled stepping motor of the one piece this time, hang one to move the probe on the stepping motor, the probe touches water, then the one-chip computer gathers to the si

🔗 External reference