Tube mic Connecting the capsule 1

Even in the simplest tube microphone circuits, there are different methods for connecting the microphone capsule to the tube. A single-sided microphone capsule will be used as the starting point. The capsule functions as a variable capacitor, altering its capacitance in response to changes in air pressure (i.e., sound). To generate a signal, the capsule requires polarization by a voltage, creating a potential difference between the diaphragm and the back plate. The first decision to make is whether to apply the polarizing voltage to the diaphragm or the capsule backplate. In the circuit shown, the backplate of the microphone is polarized at 60V, sourced from the B+ supply through a resistive divider and a small capacitor to stabilize and filter the polarizing voltage. The membrane connects directly to the tube grid, and a high-value resistor (Rg, typically 100 kΩ to 1000 kΩ) connects both the grid and the membrane to ground. This creates a potential difference across the membrane, and the microphone’s sensitivity can be adjusted by varying the polarization voltage. As the capacitance of the capsule changes in response to sound, a small current flows through Rg, which is amplified by the tube. In some designs, the grid resistor may be omitted. In an alternative circuit described by Dave Royer in Tape Op magazine, the capsule diaphragm is grounded by grid leakage rather than a physical resistor, which functions effectively. However, this arrangement is not feasible when the capsule backplate is mechanically and electrically connected to the microphone body, necessitating direct polarization of the diaphragm. Applying approximately 60V to the tube grid would adversely affect the operating points of the tube circuit, thus requiring a capacitor to block the DC voltage. Some listeners claim to discern differences between capacitor types, so a high-quality capacitor is typically recommended for this application. An additional high-value polarizing resistor is also necessary to prevent attenuation of the high-impedance audio signal through the stabilization capacitor. An example of this connection method is the Neumann-Gefell CMV563, designed for use with bayonet-style capsules such as the M7, M8, and M9.

In a typical tube microphone circuit, the configuration of the microphone capsule is crucial for optimal performance. The single-sided microphone capsule operates by varying its capacitance due to sound pressure variations. This capacitance change is essential for generating an audio signal, necessitating a polarization voltage to maintain a potential difference across the diaphragm and backplate. The choice of applying this voltage to the diaphragm versus the backplate can significantly influence the circuit design and performance.

In the specified circuit, the backplate is polarized at 60V, achieved through a resistive divider connected to the high-voltage B+ supply. A capacitor is incorporated to filter and stabilize the polarizing voltage, ensuring consistent performance. The diaphragm, which is directly linked to the tube grid, allows for an efficient transfer of the audio signal. The high-value resistor Rg serves to ground both the grid and the membrane, establishing the necessary potential difference that enables the microphone to function effectively.

The sensitivity of the microphone can be fine-tuned by adjusting the polarization voltage, allowing for adaptability in various acoustic environments. The small current generated by the changing capacitance is amplified by the tube, resulting in a clear audio output. Notably, the omission of the grid resistor in certain designs, as highlighted in Royer's article, showcases an alternative approach that can yield effective results while simplifying the circuit.

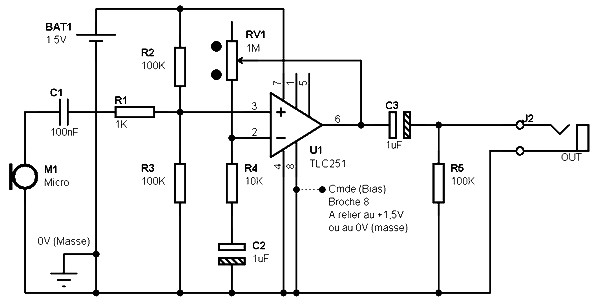

When the capsule backplate is connected to the microphone body, the design constraints change. Direct polarization of the diaphragm becomes necessary to maintain functionality. However, care must be taken to block the DC voltage from affecting the tube's operating points, which is achieved through the use of a coupling capacitor. The choice of capacitor is critical, as different types may impart varying characteristics to the audio signal, thus a high-quality capacitor is recommended for this application.

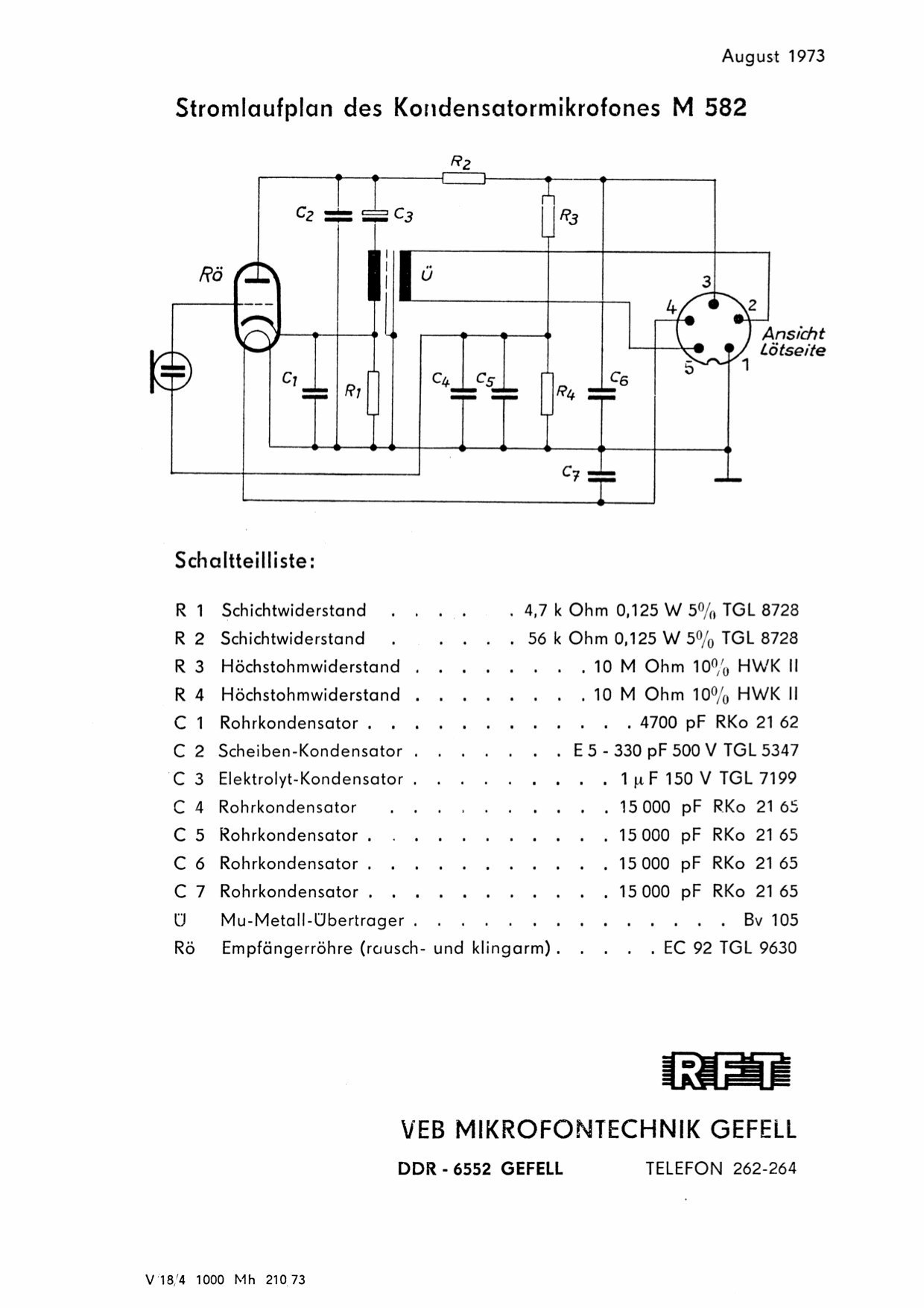

Lastly, the inclusion of an additional high-value polarizing resistor is vital to maintain the integrity of the audio signal, preventing attenuation that could arise from the stabilizing capacitor. The Neumann-Gefell CMV563 exemplifies this approach, being compatible with bayonet-style capsules, thereby illustrating the practical application of these concepts in professional audio equipment design.Even in the simplest of tube microphone circuits, there are different approaches to connecting the microphone capsule to the tube. Let`s use a single-sided microphone capsule as our starting point. The capsule behaves as a variable capacitor, changing its capacitance in response to changes in air pressure (i.

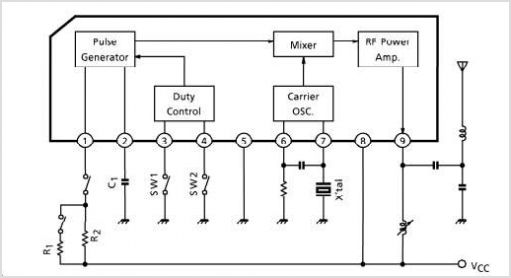

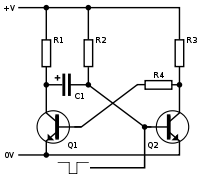

e. sound). In order to generate a signal , the capsule needs to be polarised by some voltage, creating a difference in potential between the diaphragm and the back plate. This is the first decision that needs to be made - should the polarising voltage be applied to the diaphragm or the capsule backplate In the circuit shown on the left, the backplate of the microphone is polarised at 60V, which is obtained from the B+ supply, via a resistive divider and a small capacitor to stabilise and filter the polarising voltage.

The membrane is connected directly to the tube grid, and a high value resistor (Rg, typically 100 k ©to 1000 k ©) connects both the grid and the membrane to ground. We have our potential difference across the membrane, and the sensitivity of the mic may be adjusted by increasing and decreasing the polarisation voltage.

As the capacitance of the capsule changes in response to sound, a tiny current will flow through Rg, and this signal is amplified by the tube. In some cases the grid resistor may be omitted. In the circuit below, which appeared in an article in Tape Op magazine by Dave Royer, the capsule diaphragm is grounded by grid leakage rather than a `real` resistor.

It works perfectly. This simple arrangement is not possible when the capsule backplate is mechanically (and electrically) connected to the body of the microphone. In this case the diaphragm must be polarised directly. However, having a voltage of around 60V on the tube grid this would adversely change the operating points of the tube circuit, and so a capacitor must be used to block the DC voltage (left).

Some listeners claim to hear the difference between different types of capacitors, and so normally a very high quality type should be used in this position. An additional high value polarising resistor is also required, otherwise the high impedance audio signal would be attenuated through the stabilisation cap.

An example of this method of connection is the Neumann-Gefell CMV563, which is designed to be used with bayonette style capsules such as the M7, M8 and M9. 🔗 External reference

In a typical tube microphone circuit, the configuration of the microphone capsule is crucial for optimal performance. The single-sided microphone capsule operates by varying its capacitance due to sound pressure variations. This capacitance change is essential for generating an audio signal, necessitating a polarization voltage to maintain a potential difference across the diaphragm and backplate. The choice of applying this voltage to the diaphragm versus the backplate can significantly influence the circuit design and performance.

In the specified circuit, the backplate is polarized at 60V, achieved through a resistive divider connected to the high-voltage B+ supply. A capacitor is incorporated to filter and stabilize the polarizing voltage, ensuring consistent performance. The diaphragm, which is directly linked to the tube grid, allows for an efficient transfer of the audio signal. The high-value resistor Rg serves to ground both the grid and the membrane, establishing the necessary potential difference that enables the microphone to function effectively.

The sensitivity of the microphone can be fine-tuned by adjusting the polarization voltage, allowing for adaptability in various acoustic environments. The small current generated by the changing capacitance is amplified by the tube, resulting in a clear audio output. Notably, the omission of the grid resistor in certain designs, as highlighted in Royer's article, showcases an alternative approach that can yield effective results while simplifying the circuit.

When the capsule backplate is connected to the microphone body, the design constraints change. Direct polarization of the diaphragm becomes necessary to maintain functionality. However, care must be taken to block the DC voltage from affecting the tube's operating points, which is achieved through the use of a coupling capacitor. The choice of capacitor is critical, as different types may impart varying characteristics to the audio signal, thus a high-quality capacitor is recommended for this application.

Lastly, the inclusion of an additional high-value polarizing resistor is vital to maintain the integrity of the audio signal, preventing attenuation that could arise from the stabilizing capacitor. The Neumann-Gefell CMV563 exemplifies this approach, being compatible with bayonet-style capsules, thereby illustrating the practical application of these concepts in professional audio equipment design.Even in the simplest of tube microphone circuits, there are different approaches to connecting the microphone capsule to the tube. Let`s use a single-sided microphone capsule as our starting point. The capsule behaves as a variable capacitor, changing its capacitance in response to changes in air pressure (i.

e. sound). In order to generate a signal , the capsule needs to be polarised by some voltage, creating a difference in potential between the diaphragm and the back plate. This is the first decision that needs to be made - should the polarising voltage be applied to the diaphragm or the capsule backplate In the circuit shown on the left, the backplate of the microphone is polarised at 60V, which is obtained from the B+ supply, via a resistive divider and a small capacitor to stabilise and filter the polarising voltage.

The membrane is connected directly to the tube grid, and a high value resistor (Rg, typically 100 k ©to 1000 k ©) connects both the grid and the membrane to ground. We have our potential difference across the membrane, and the sensitivity of the mic may be adjusted by increasing and decreasing the polarisation voltage.

As the capacitance of the capsule changes in response to sound, a tiny current will flow through Rg, and this signal is amplified by the tube. In some cases the grid resistor may be omitted. In the circuit below, which appeared in an article in Tape Op magazine by Dave Royer, the capsule diaphragm is grounded by grid leakage rather than a `real` resistor.

It works perfectly. This simple arrangement is not possible when the capsule backplate is mechanically (and electrically) connected to the body of the microphone. In this case the diaphragm must be polarised directly. However, having a voltage of around 60V on the tube grid this would adversely change the operating points of the tube circuit, and so a capacitor must be used to block the DC voltage (left).

Some listeners claim to hear the difference between different types of capacitors, and so normally a very high quality type should be used in this position. An additional high value polarising resistor is also required, otherwise the high impedance audio signal would be attenuated through the stabilisation cap.

An example of this method of connection is the Neumann-Gefell CMV563, which is designed to be used with bayonette style capsules such as the M7, M8 and M9. 🔗 External reference