Tube mic Connecting the capsule 2

Connecting a condenser capsule to the grid of a tube amplifier to build a tube microphone. This section discusses how to connect a capsule with two diaphragms to achieve a multi-pattern microphone. First, the different pickup patterns are examined: Omni, where the microphone captures sound equally from all directions; Cardioid, where sensitivity is highest in the direction the microphone faces, decreasing to a null point behind; and Figure-of-Eight, which captures sound equally from the front and back while nullifying sound from the sides. The pickup pattern can vary with frequency, with some microphones exhibiting good directionality at higher frequencies but becoming less directional at lower frequencies. For a microphone with selectable patterns, a pair of cardioid capsules can be arranged back-to-back, mixing their signals in various ways. The front and back capsules can be used to create different patterns: for cardioid, only the front capsule is used; for omnidirectional, both signals are mixed equally; and for figure of eight, the rear signal is subtracted from the front, creating null points at the sides. Other patterns, such as hyper-cardioid and super-cardioid, can be considered intermediate positions. The Neumann U47, which offers cardioid and omnidirectional settings, is a practical example of this configuration. In the U47, the front diaphragm is grounded through a 100 Megohm grid resistor, while the backplate is polarized with approximately 60V. The rear diaphragm connects to a switch that, when open, activates only the front cardioid diaphragm. Closing the switch allows the rear capsule to contribute to the front, creating an omnidirectional microphone. The U48 requires a different approach for figure-of-eight patterns, necessitating the inversion of the rear diaphragm's polarity. This involves raising the rear diaphragm's potential to 60V above the backplate and 120V above the front capsule, which can be achieved using the high-tension supply to the tube's anode. A blocking capacitor is required to prevent direct connection between the two diaphragms due to their differing potentials. To create a variable pattern microphone, an adjustable supply from 0V to 120V can be applied to the backplate, or the signal may be taken from the backplate through a capacitor to the tube grid. The Neumann-Gefell UM57 implements this method, incorporating a pattern selector in the power supply.

The construction of a tube microphone with multiple pickup patterns involves careful consideration of the design and functionality of the microphone's components. The use of condenser capsules with dual diaphragms allows for the creation of various directional characteristics, enhancing the microphone's versatility in different recording environments. The arrangement of the capsules is critical; positioning them back-to-back facilitates the mixing of their outputs in a manner that can produce the desired sound pickup pattern.

In practical applications, the U47 and U48 models serve as benchmarks for this design philosophy. The U47's approach to grounding the front diaphragm while polarizing the backplate creates a stable reference for the cardioid pattern, while the switch mechanism allows for straightforward toggling between cardioid and omnidirectional settings. This simplicity in operation is essential for users who may require quick adjustments while recording.

The U48's implementation of figure-of-eight pattern necessitates a more complex circuit due to the requirement of inverting the rear diaphragm's polarity. This inversion is crucial for achieving the desired sound cancellation at the microphone's sides, allowing for focused sound capture from the front and rear. The addition of a blocking capacitor is a vital step to ensure that the differing potentials of the diaphragms do not interfere with one another, thereby preserving the integrity of the audio signal.

To facilitate the variable pattern functionality, the adjustable supply voltage offers users the ability to fine-tune the microphone's characteristics in real-time. This feature is particularly beneficial in professional recording settings where adaptability to different sound sources and environments is paramount. The integration of such technology into the power supply, as seen in the Neumann-Gefell UM57, exemplifies the innovative approaches taken in modern microphone design, providing users with enhanced control over their recording capabilities. Overall, the design and operation of multi-pattern tube microphones represent a sophisticated blend of electrical engineering and acoustic principles, allowing for a broad range of applications in audio recording.Connecting a condenser capsule to the grid of a tube amplifier, in order to build a tube mic. In this part we consider how to connect a capsule with two diaphragms in order to get a multi-pattern mic. First let`s examine the different pickup patterns available. There are three extremes: Omni, where the microphone hears sounds equally in all directions. Cardioid (heart shaped*), where sensitivity is greatest in the direction in which the microphone is pointing, falling off to a null point behind. And Figure-of-Eight, with equal (but opposite) pickup in front and behind, and null pickup to the sides. To complicate things further, the pickup pattern may depend upon the frequency, and some mics will have good directionality at higher frequencies, but become less directional as the frequency drops.

But what if we want a microphone with selectable pattern This can be achieved by arranging a pair of cardioid capsules back-to-back, and combining there signals in different ways. We`ll call these capsules front and back, although of course they could be pointing in any direction.

If we require a cardioid signal, we just take the front capsule and for omnidirectional pickup, we mix both signals equally. If we want figure of eight, we subtract the output of the rear from the front: where the signals overlap at the sides of the microphone, they cancel each other out producing null points.

Other patterns such as hyper-cardioid and super-cardioid may be considered as in-between positions of these extremes. So, what is the best way to achieve this practically in our hypothetical tube microphone Two of the earliest commercial mics with more than one pattern were the Neumann U47, which offered cardioid and omni, and the U48, with cardioid & fig.

8. Let`s look at the U47, as this is probably the simplest way to combine the two capsules. In the U47 the front diaphragm is grounded through a 100 Meg grid resistor, and the backplate of the microphone`s dual diaphragm is polarised with about 60V, providing the potential difference required. The rear diaphragm is connected to a switch. When the switch is open, the rear capsule is left floating and only the front cardioid diaphragm is active.

When the switch is closed, the rear capsule adds its contribution to the front, making an omnidirectional microphone. What about the U48 We have seen above that if we require figure of 8 instead of omnidirectional, we must subtract, rather than add, the sounds from the rear.

To do this we must invert the polarity of the rear diaphragm by reversing its relative charge. So, rather than grounding the rear diaphragm, we must raise the potential by 60V* above the backplate, and 120V above the front capsule! This is easily achieved by using the HT supply to the anode of the tube, but creates another problem.

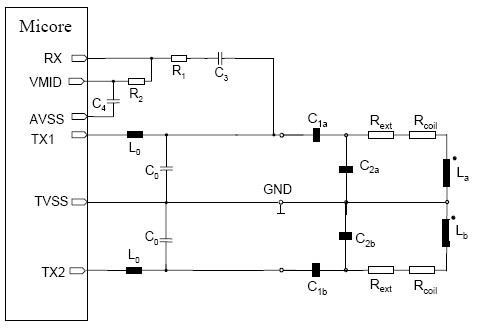

We can`t simply connect the two diaphragms because they are now at different potentials, and so a blocking capacitor must be used. The circuit looks like this: Finally, to make the microphone have variable pattern, we simply need to make a supply that is adjustable from 0V to 120V, and apply that to the backplate.

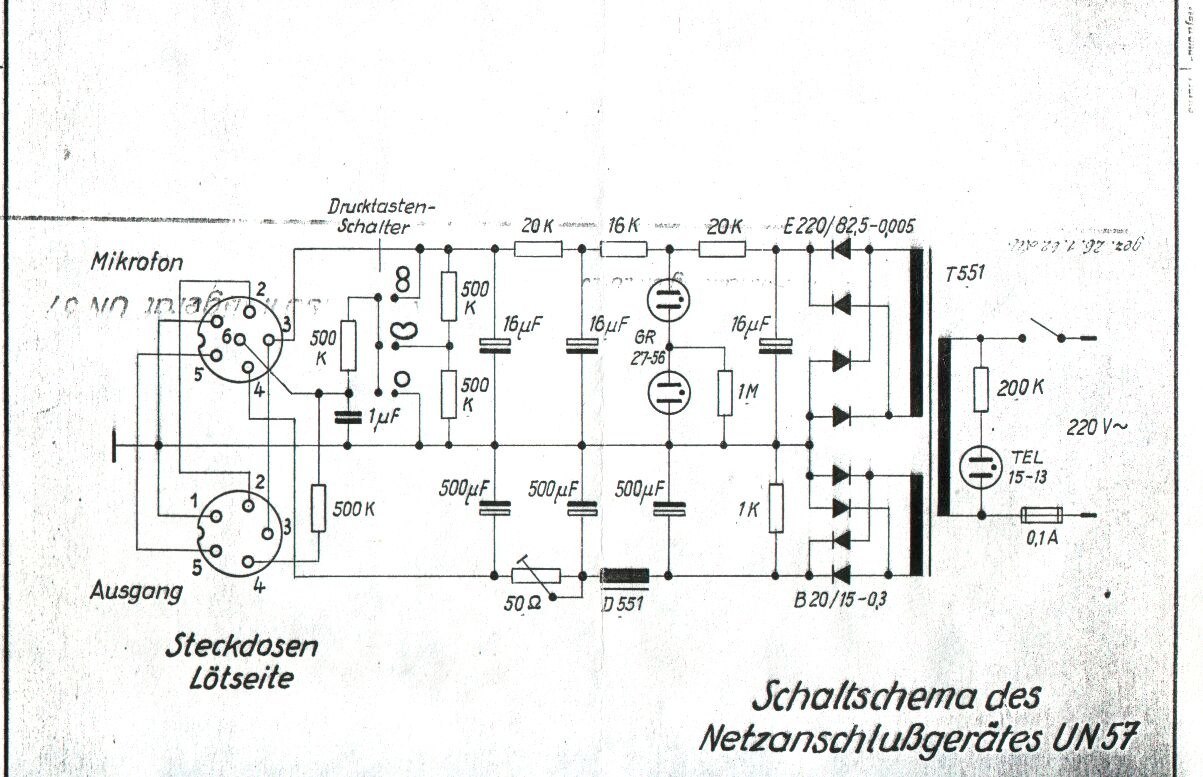

Alternatively, the signal may be taken from the backplate, through a capacitor to the tube grid. The Neumann-Gefell UM57 does it exactly this way, with the pattern selector in the power supply. 🔗 External reference

The construction of a tube microphone with multiple pickup patterns involves careful consideration of the design and functionality of the microphone's components. The use of condenser capsules with dual diaphragms allows for the creation of various directional characteristics, enhancing the microphone's versatility in different recording environments. The arrangement of the capsules is critical; positioning them back-to-back facilitates the mixing of their outputs in a manner that can produce the desired sound pickup pattern.

In practical applications, the U47 and U48 models serve as benchmarks for this design philosophy. The U47's approach to grounding the front diaphragm while polarizing the backplate creates a stable reference for the cardioid pattern, while the switch mechanism allows for straightforward toggling between cardioid and omnidirectional settings. This simplicity in operation is essential for users who may require quick adjustments while recording.

The U48's implementation of figure-of-eight pattern necessitates a more complex circuit due to the requirement of inverting the rear diaphragm's polarity. This inversion is crucial for achieving the desired sound cancellation at the microphone's sides, allowing for focused sound capture from the front and rear. The addition of a blocking capacitor is a vital step to ensure that the differing potentials of the diaphragms do not interfere with one another, thereby preserving the integrity of the audio signal.

To facilitate the variable pattern functionality, the adjustable supply voltage offers users the ability to fine-tune the microphone's characteristics in real-time. This feature is particularly beneficial in professional recording settings where adaptability to different sound sources and environments is paramount. The integration of such technology into the power supply, as seen in the Neumann-Gefell UM57, exemplifies the innovative approaches taken in modern microphone design, providing users with enhanced control over their recording capabilities. Overall, the design and operation of multi-pattern tube microphones represent a sophisticated blend of electrical engineering and acoustic principles, allowing for a broad range of applications in audio recording.Connecting a condenser capsule to the grid of a tube amplifier, in order to build a tube mic. In this part we consider how to connect a capsule with two diaphragms in order to get a multi-pattern mic. First let`s examine the different pickup patterns available. There are three extremes: Omni, where the microphone hears sounds equally in all directions. Cardioid (heart shaped*), where sensitivity is greatest in the direction in which the microphone is pointing, falling off to a null point behind. And Figure-of-Eight, with equal (but opposite) pickup in front and behind, and null pickup to the sides. To complicate things further, the pickup pattern may depend upon the frequency, and some mics will have good directionality at higher frequencies, but become less directional as the frequency drops.

But what if we want a microphone with selectable pattern This can be achieved by arranging a pair of cardioid capsules back-to-back, and combining there signals in different ways. We`ll call these capsules front and back, although of course they could be pointing in any direction.

If we require a cardioid signal, we just take the front capsule and for omnidirectional pickup, we mix both signals equally. If we want figure of eight, we subtract the output of the rear from the front: where the signals overlap at the sides of the microphone, they cancel each other out producing null points.

Other patterns such as hyper-cardioid and super-cardioid may be considered as in-between positions of these extremes. So, what is the best way to achieve this practically in our hypothetical tube microphone Two of the earliest commercial mics with more than one pattern were the Neumann U47, which offered cardioid and omni, and the U48, with cardioid & fig.

8. Let`s look at the U47, as this is probably the simplest way to combine the two capsules. In the U47 the front diaphragm is grounded through a 100 Meg grid resistor, and the backplate of the microphone`s dual diaphragm is polarised with about 60V, providing the potential difference required. The rear diaphragm is connected to a switch. When the switch is open, the rear capsule is left floating and only the front cardioid diaphragm is active.

When the switch is closed, the rear capsule adds its contribution to the front, making an omnidirectional microphone. What about the U48 We have seen above that if we require figure of 8 instead of omnidirectional, we must subtract, rather than add, the sounds from the rear.

To do this we must invert the polarity of the rear diaphragm by reversing its relative charge. So, rather than grounding the rear diaphragm, we must raise the potential by 60V* above the backplate, and 120V above the front capsule! This is easily achieved by using the HT supply to the anode of the tube, but creates another problem.

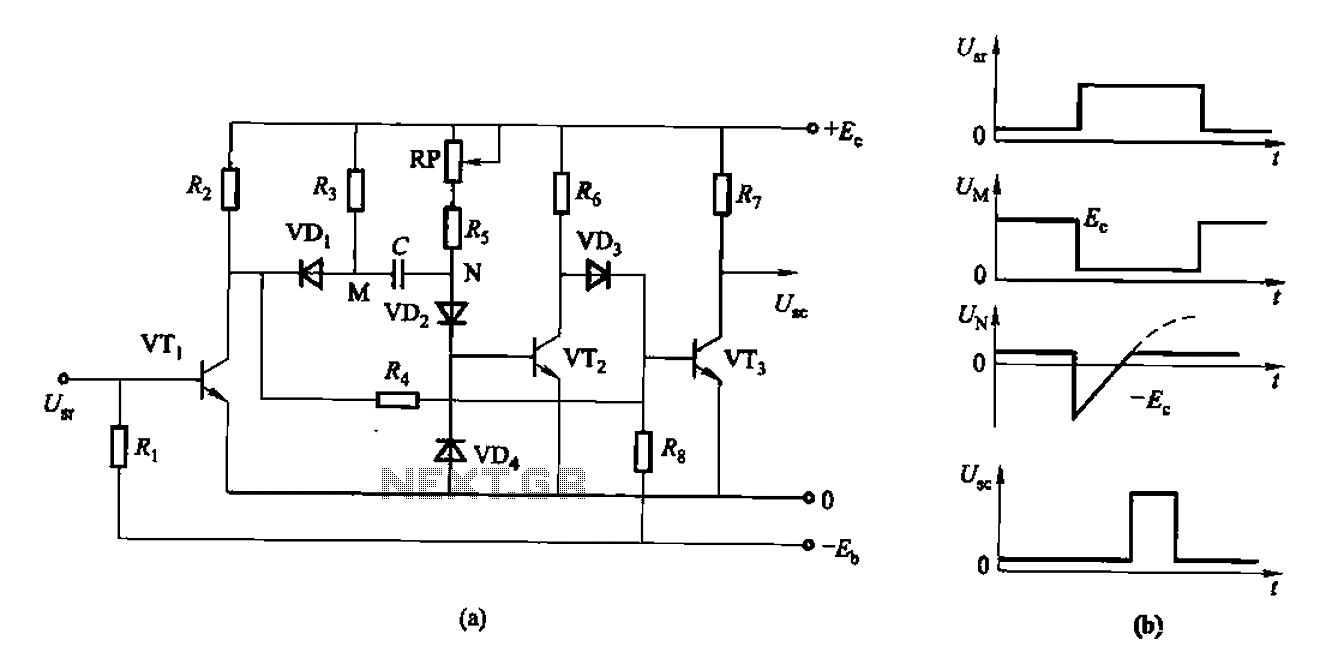

We can`t simply connect the two diaphragms because they are now at different potentials, and so a blocking capacitor must be used. The circuit looks like this: Finally, to make the microphone have variable pattern, we simply need to make a supply that is adjustable from 0V to 120V, and apply that to the backplate.

Alternatively, the signal may be taken from the backplate, through a capacitor to the tube grid. The Neumann-Gefell UM57 does it exactly this way, with the pattern selector in the power supply. 🔗 External reference