Two Wires-Stepper Motor Controller

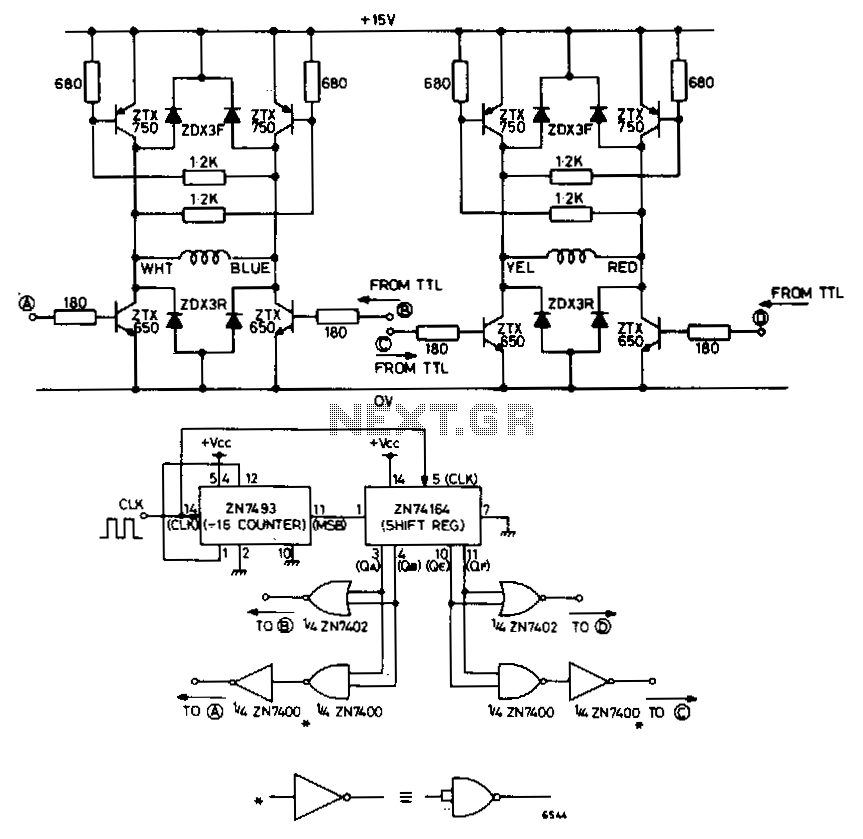

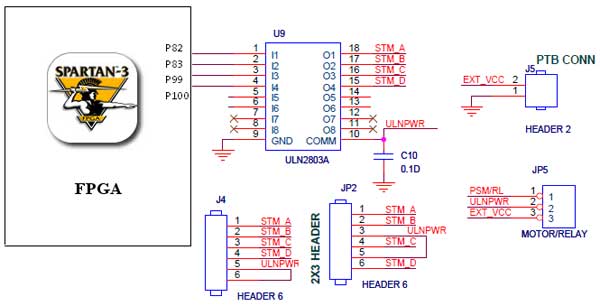

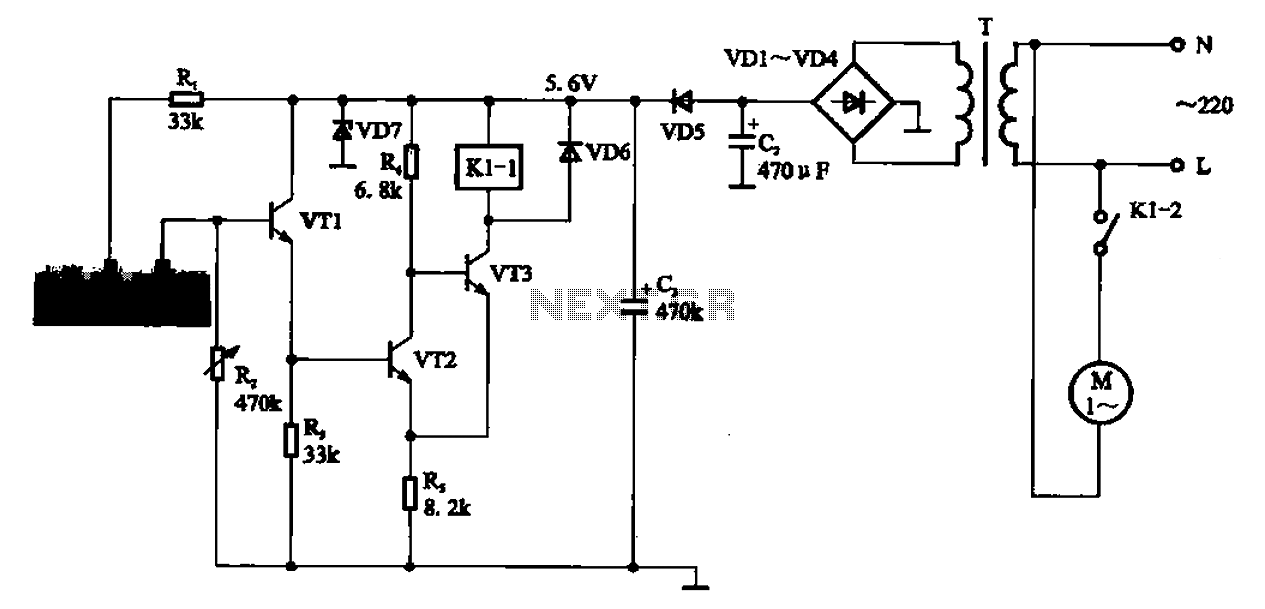

To achieve a low-cost, accurate, and simple position control system, a stepper motor can be utilized. A circuit designed to drive the motor should be mounted in proximity to the motor itself.

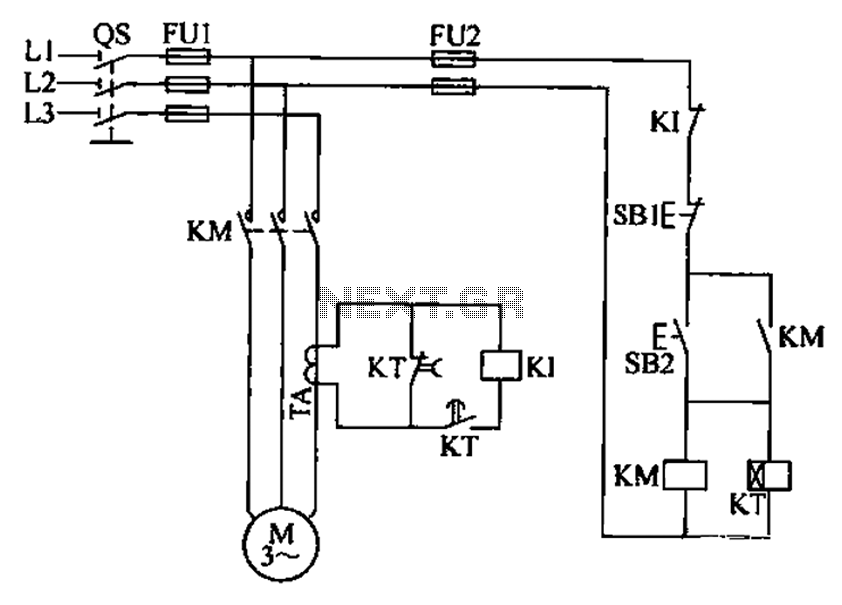

Stepper motors are widely employed in applications requiring precise control of angular position, velocity, and acceleration. They operate by dividing a full rotation into a series of discrete steps, allowing for fine control over movement. The driving circuit for a stepper motor typically consists of a microcontroller or a dedicated driver IC that sends pulse signals to the motor coils in a specific sequence, enabling the motor to rotate in precise increments.

A common configuration for the drive circuit involves using an H-bridge arrangement, which allows for bi-directional control of the motor. This setup enables the motor to rotate clockwise or counterclockwise based on the polarity of the signals applied to the motor windings. The circuit should also include current limiting resistors or a current sensing mechanism to prevent overheating and ensure the longevity of the motor.

To enhance accuracy, feedback mechanisms such as encoders can be integrated into the system. These devices provide real-time position data, allowing for closed-loop control, which adjusts the motor's operation based on the actual position versus the desired position. The design should also consider power supply requirements, ensuring that the voltage and current ratings meet the specifications of the stepper motor being used.

In summary, the implementation of a stepper motor control circuit involves careful consideration of the driving method, feedback mechanisms, and power supply, all contributing to an effective and reliable position control system.To get a position control that are low cost, accurate and simple we can use stepper motor. To drive it we can use a circuit mounted close to the motor, and to.. 🔗 External reference

Stepper motors are widely employed in applications requiring precise control of angular position, velocity, and acceleration. They operate by dividing a full rotation into a series of discrete steps, allowing for fine control over movement. The driving circuit for a stepper motor typically consists of a microcontroller or a dedicated driver IC that sends pulse signals to the motor coils in a specific sequence, enabling the motor to rotate in precise increments.

A common configuration for the drive circuit involves using an H-bridge arrangement, which allows for bi-directional control of the motor. This setup enables the motor to rotate clockwise or counterclockwise based on the polarity of the signals applied to the motor windings. The circuit should also include current limiting resistors or a current sensing mechanism to prevent overheating and ensure the longevity of the motor.

To enhance accuracy, feedback mechanisms such as encoders can be integrated into the system. These devices provide real-time position data, allowing for closed-loop control, which adjusts the motor's operation based on the actual position versus the desired position. The design should also consider power supply requirements, ensuring that the voltage and current ratings meet the specifications of the stepper motor being used.

In summary, the implementation of a stepper motor control circuit involves careful consideration of the driving method, feedback mechanisms, and power supply, all contributing to an effective and reliable position control system.To get a position control that are low cost, accurate and simple we can use stepper motor. To drive it we can use a circuit mounted close to the motor, and to.. 🔗 External reference