Ultrasonic remote control switch circuit diagram

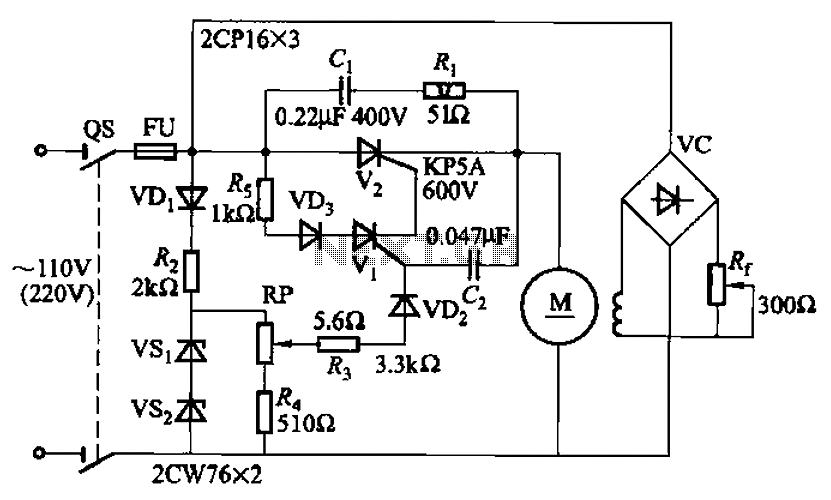

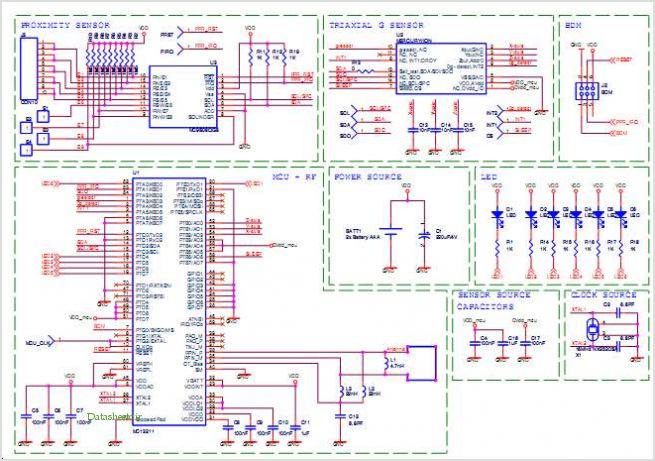

Many brands in Asia utilize ultrasonic remote control switch circuits, with some employing relays and others utilizing thyristors. The remote control transmitter is of a puffer type, featuring an ultrasound flute with both olive and flat circular shapes. This document presents a typical circuit diagram and discusses its operation and troubleshooting in two scenarios. The first scenario involves an AC220V circuit with C1 acting as a buck converter, while VD1 and VD2 serve as rectifiers. C2, following VD3, functions as a filter regulator to provide operating power to the control circuit. BM represents a piezoelectric ultrasonic receiving sensor, while R2 and L form a sub-ultrasonic resonance circuit. VT3 and VT4 create a flip-flop, and VT5 controls relay K, which executes the control circuit. CZ is responsible for the load sockets. The second part describes maintenance examples. In the first example, upon receiving commands from the remote control, the VD7 indicator lamp blinks rapidly, accompanied by mechanical noise from the relay armature. After one second, the relay stops, and both the control bulbs and VD7 extinguish. This failure may occur if the mains voltage drops below 180V or if the capacity of capacitor C1 is insufficient, leading to inadequate DC power supply. Measuring the mains voltage can help diagnose the issue, and replacing a degraded C1 (originally 0.32 F) with a 0.47 F / 400V polyester capacitor can resolve the problem. Additionally, a failure in C2 can produce similar symptoms. In the second example, each remote control command results in the LED bulbs controlled by VD7 entering a stable state after several flashes. The trigger pulse generation circuit utilizes R3 as the collector load resistor of VT2, outputting a trigger signal, while C5 prevents erroneous signals. If C5 fails, replacing it with a 2.2 F / 16V electrolytic capacitor resolves the issue. It has been observed that C5 values typically range from 0.47 F to 3.3 F, with larger capacities resulting in longer response times for the remote control switch.

The ultrasonic remote control switch circuit operates by harnessing ultrasonic signals to trigger electronic components effectively. The circuit is designed to convert AC mains voltage into a usable DC voltage through a series of components. The buck converter (C1) reduces the voltage, while the rectifier diodes (VD1, VD2) convert the AC signal to DC. The filtering capacitor (C2) smooths the output, ensuring a stable voltage supply for the control circuit, which is essential for reliable operation.

The piezoelectric ultrasonic sensor (BM) detects ultrasonic signals emitted by the remote control. The resonance circuit formed by R2 and L enhances the sensitivity of the receiver, allowing it to respond to specific frequencies associated with the transmitter. The flip-flop configuration (VT3 and VT4) is crucial for processing the received signals and ensuring that the relay (VT5) operates correctly to control the connected load (CZ).

Troubleshooting involves assessing the performance of key components, particularly the capacitors (C1 and C2) and the LED indicator (VD7). A drop in mains voltage can lead to insufficient power supply, causing the relay to fail to engage properly. Regular maintenance ensures that capacitors are within operational specifications, as their degradation can significantly impact circuit performance.

The design emphasizes the importance of component selection, as the values of C5 can influence the response time of the circuit. A well-optimized circuit will balance the capacitance values to achieve a quick response while maintaining stability. This intricate interplay of components allows for effective remote control functionality, making it suitable for a variety of applications in consumer electronics.Many brands and Asia ultrasonic remote control switch circuit form, the control device to perform some use of relay; others use thyristors. The use of remote control transmitter puffer type sub ultrasound flute (which have olive and flat circular shape). In this paper, a typical circuit shown in the drawings, for example, it works Introduction and troubleshooting two cases. First, the circuit AC220V by C1 Buck, VD1, VD2 rectifier; C2, after VD3 filter regulator control circuit to receive operating power.

BM is a piezoelectric ultrasonic receiving sensor sub; R2, L constitute a sub ultrasonic resonance circuit; VT3, VT4 constitute flip-flop; VT5 relay K composition and execution control circuit; CZ is charged with the load sockets. Second, Maintenance Examples [Example 1] after receiving the transmitter remote control commands, and controlled VD7 indicator lamp blinks in rapid succession at the same time, and you will hear mechanical noise generated when the relay armature trembling, after one second, warble stop by control bulbs and VD7 simultaneously extinguished.

This failure often occurs in remote switching power supply circuit, when the mains voltage is lower than 180V or down capacitor C1 of insufficient capacity, both due to the DC power supply to the machine is not sufficient to provide the required operating current, resulting in the drive circuit and relay difficult to successfully enter the normal pull-state performance of sorption is not strong, like non-absorbent such as smoking. After measuring the mains is normal, then remove the C1, measured obtaining capacity 0.32 F, capacity has been significantly reduced.

Put a 0.47 F / 400V polyester capacitor, troubleshooting. In addition, if C2 failure (no capacity) will lead to the same symptoms in this case. [Example 2] at each remote control lights, LED bulbs have VD7 and controlled in order to enter the stable after several flashing light-emitting state. The trigger pulse generation circuit, R3 is the collector load resistor VT2 from R3 output a trigger signal; C5 to prevent misunderstandings hair.

Failure in this case C5, a substitution electrolytic capacitor 2.2 F / 16V after the fault is cleared. Practice has proved that, C5 ranges generally between 0.47 ~ 3.3 F compare properly. In general, the capacity of the election was large, remote control switch response time is relatively longer, shorter and vice versa.

The ultrasonic remote control switch circuit operates by harnessing ultrasonic signals to trigger electronic components effectively. The circuit is designed to convert AC mains voltage into a usable DC voltage through a series of components. The buck converter (C1) reduces the voltage, while the rectifier diodes (VD1, VD2) convert the AC signal to DC. The filtering capacitor (C2) smooths the output, ensuring a stable voltage supply for the control circuit, which is essential for reliable operation.

The piezoelectric ultrasonic sensor (BM) detects ultrasonic signals emitted by the remote control. The resonance circuit formed by R2 and L enhances the sensitivity of the receiver, allowing it to respond to specific frequencies associated with the transmitter. The flip-flop configuration (VT3 and VT4) is crucial for processing the received signals and ensuring that the relay (VT5) operates correctly to control the connected load (CZ).

Troubleshooting involves assessing the performance of key components, particularly the capacitors (C1 and C2) and the LED indicator (VD7). A drop in mains voltage can lead to insufficient power supply, causing the relay to fail to engage properly. Regular maintenance ensures that capacitors are within operational specifications, as their degradation can significantly impact circuit performance.

The design emphasizes the importance of component selection, as the values of C5 can influence the response time of the circuit. A well-optimized circuit will balance the capacitance values to achieve a quick response while maintaining stability. This intricate interplay of components allows for effective remote control functionality, making it suitable for a variety of applications in consumer electronics.Many brands and Asia ultrasonic remote control switch circuit form, the control device to perform some use of relay; others use thyristors. The use of remote control transmitter puffer type sub ultrasound flute (which have olive and flat circular shape). In this paper, a typical circuit shown in the drawings, for example, it works Introduction and troubleshooting two cases. First, the circuit AC220V by C1 Buck, VD1, VD2 rectifier; C2, after VD3 filter regulator control circuit to receive operating power.

BM is a piezoelectric ultrasonic receiving sensor sub; R2, L constitute a sub ultrasonic resonance circuit; VT3, VT4 constitute flip-flop; VT5 relay K composition and execution control circuit; CZ is charged with the load sockets. Second, Maintenance Examples [Example 1] after receiving the transmitter remote control commands, and controlled VD7 indicator lamp blinks in rapid succession at the same time, and you will hear mechanical noise generated when the relay armature trembling, after one second, warble stop by control bulbs and VD7 simultaneously extinguished.

This failure often occurs in remote switching power supply circuit, when the mains voltage is lower than 180V or down capacitor C1 of insufficient capacity, both due to the DC power supply to the machine is not sufficient to provide the required operating current, resulting in the drive circuit and relay difficult to successfully enter the normal pull-state performance of sorption is not strong, like non-absorbent such as smoking. After measuring the mains is normal, then remove the C1, measured obtaining capacity 0.32 F, capacity has been significantly reduced.

Put a 0.47 F / 400V polyester capacitor, troubleshooting. In addition, if C2 failure (no capacity) will lead to the same symptoms in this case. [Example 2] at each remote control lights, LED bulbs have VD7 and controlled in order to enter the stable after several flashing light-emitting state. The trigger pulse generation circuit, R3 is the collector load resistor VT2 from R3 output a trigger signal; C5 to prevent misunderstandings hair.

Failure in this case C5, a substitution electrolytic capacitor 2.2 F / 16V after the fault is cleared. Practice has proved that, C5 ranges generally between 0.47 ~ 3.3 F compare properly. In general, the capacity of the election was large, remote control switch response time is relatively longer, shorter and vice versa.