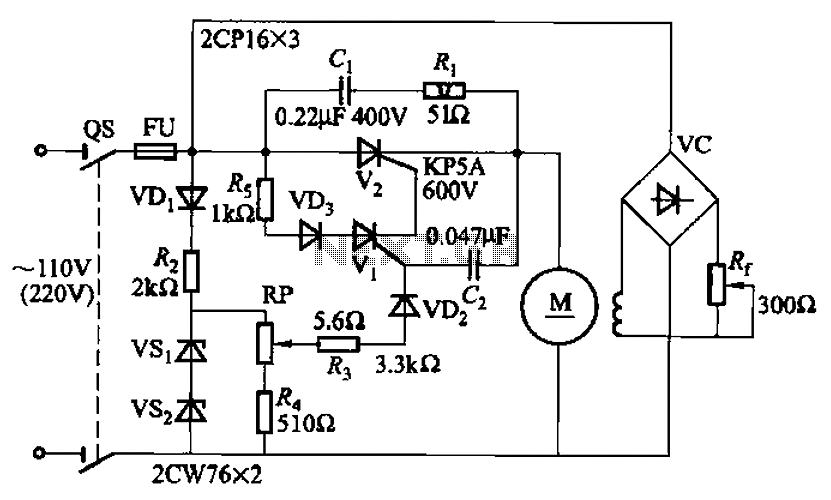

100W resistance triggered doer control circuit

A 100W resistance-triggered motor control circuit designed for arc welding machines. It features an adjustment potentiometer (Rr) that can modify the DC motor excitation current. Additionally, a regulator (RP) is included to adjust the DC motor armature voltage, enabling speed control.

This circuit is primarily utilized in arc welding applications, where precise control over the motor's operation is essential for effective welding processes. The resistance-triggered design allows for straightforward implementation, making it an ideal choice for basic welding machine setups.

The adjustment potentiometer (Rr) plays a crucial role in controlling the excitation current of the DC motor. By varying the resistance, the user can influence the magnetic field strength generated within the motor, thereby affecting its torque and overall performance. This capability is vital for adapting the welding process to different materials and thicknesses.

The regulator (RP) is responsible for controlling the armature voltage supplied to the DC motor. Adjusting this voltage directly impacts the motor's speed, allowing for fine-tuning during operation. This feature is particularly useful in welding applications where different speeds may be required depending on the welding technique or material being used.

Overall, this circuit design emphasizes simplicity and functionality, making it accessible for those involved in welding machine construction or modification. Proper implementation of the adjustment potentiometer and regulator will enable users to achieve optimal performance from their arc welding machines.100W resistance triggered doer control circuit It is dragging the arc welding machine control circuit of the most simple kind. Adjustment potentiometer Rr, can change the DC mo tor excitation current. Regulator RP, can change the DC motor armature voltage, to achieve speed control purposes.

This circuit is primarily utilized in arc welding applications, where precise control over the motor's operation is essential for effective welding processes. The resistance-triggered design allows for straightforward implementation, making it an ideal choice for basic welding machine setups.

The adjustment potentiometer (Rr) plays a crucial role in controlling the excitation current of the DC motor. By varying the resistance, the user can influence the magnetic field strength generated within the motor, thereby affecting its torque and overall performance. This capability is vital for adapting the welding process to different materials and thicknesses.

The regulator (RP) is responsible for controlling the armature voltage supplied to the DC motor. Adjusting this voltage directly impacts the motor's speed, allowing for fine-tuning during operation. This feature is particularly useful in welding applications where different speeds may be required depending on the welding technique or material being used.

Overall, this circuit design emphasizes simplicity and functionality, making it accessible for those involved in welding machine construction or modification. Proper implementation of the adjustment potentiometer and regulator will enable users to achieve optimal performance from their arc welding machines.100W resistance triggered doer control circuit It is dragging the arc welding machine control circuit of the most simple kind. Adjustment potentiometer Rr, can change the DC mo tor excitation current. Regulator RP, can change the DC motor armature voltage, to achieve speed control purposes.