Universal Triac Control with Optocoupler

This universal triac controller circuit with optocoupler addresses the issue that triacs face when operating at low temperatures, as they require a higher gate trigger voltage.

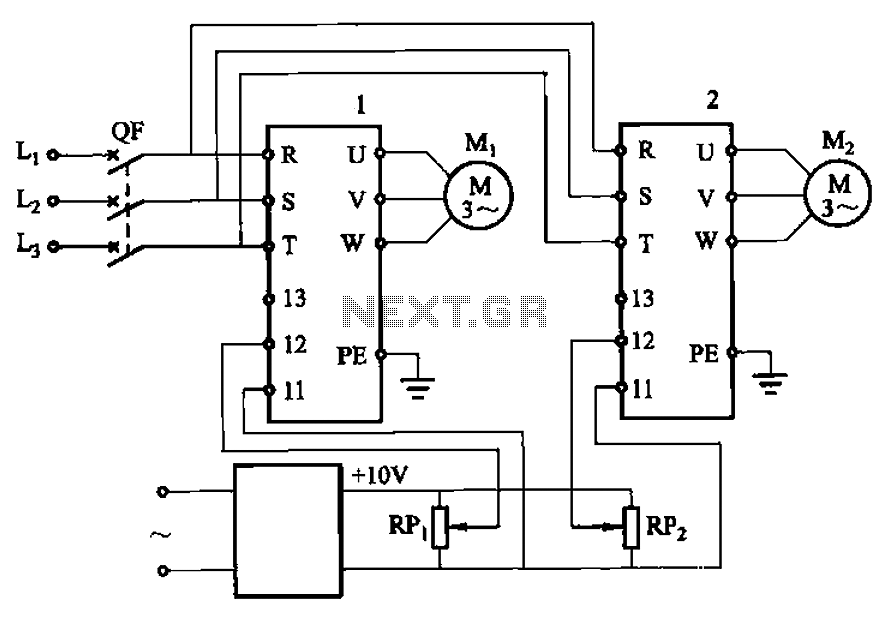

The universal triac controller circuit is designed to enhance the performance of triacs, particularly in low-temperature environments where standard operation may be compromised. The circuit employs an optocoupler to provide electrical isolation between the control side and the load side, ensuring safe operation and protecting sensitive components from high voltage spikes.

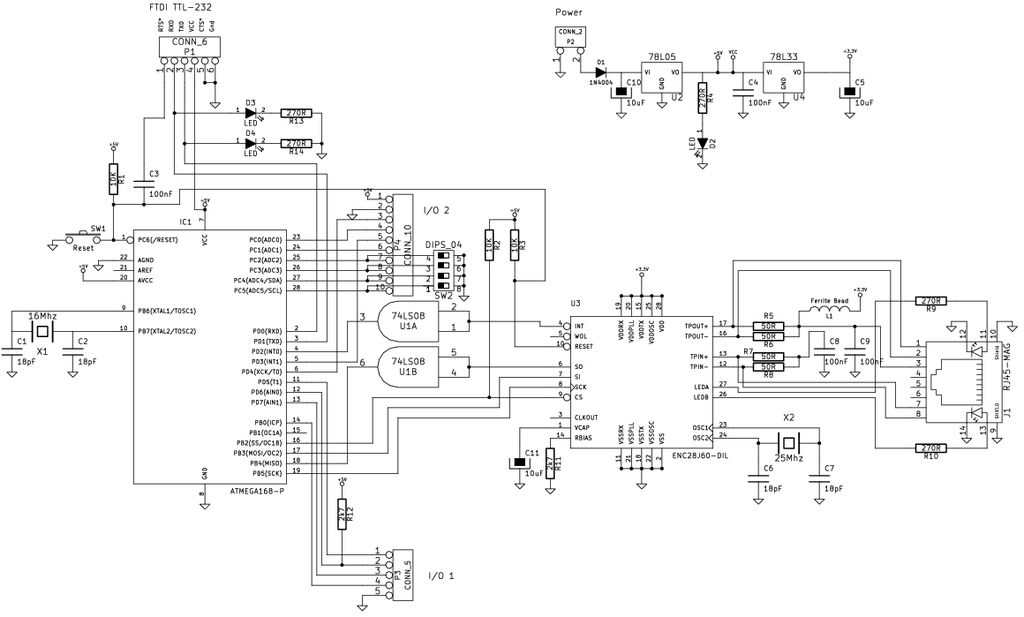

The configuration typically includes a triac, an optocoupler, resistors, and capacitors. The optocoupler is used to control the gate of the triac, allowing for low-voltage control signals to manage higher voltage loads. This is particularly advantageous in applications where the control circuit operates at a lower voltage, such as microcontrollers or digital logic circuits.

In the circuit, the optocoupler's LED is driven by the control signal, which activates the phototransistor on the output side. When the phototransistor conducts, it triggers the gate of the triac, allowing current to flow through the load. The use of a resistor in series with the LED ensures that the optocoupler operates within its specified current limits, while additional components may be employed to filter noise and stabilize the circuit.

For optimal performance, it is crucial to select a triac that matches the load specifications, including voltage and current ratings, and to ensure that the optocoupler is capable of providing sufficient gate current to trigger the triac reliably. This configuration not only improves the reliability of the triac operation in low-temperature conditions but also enhances overall circuit safety and efficiency.This universal triac controller circuit with optocoupler solves the problem that triacs have when functioning at low temperatures (triac needs higher gate. 🔗 External reference

The universal triac controller circuit is designed to enhance the performance of triacs, particularly in low-temperature environments where standard operation may be compromised. The circuit employs an optocoupler to provide electrical isolation between the control side and the load side, ensuring safe operation and protecting sensitive components from high voltage spikes.

The configuration typically includes a triac, an optocoupler, resistors, and capacitors. The optocoupler is used to control the gate of the triac, allowing for low-voltage control signals to manage higher voltage loads. This is particularly advantageous in applications where the control circuit operates at a lower voltage, such as microcontrollers or digital logic circuits.

In the circuit, the optocoupler's LED is driven by the control signal, which activates the phototransistor on the output side. When the phototransistor conducts, it triggers the gate of the triac, allowing current to flow through the load. The use of a resistor in series with the LED ensures that the optocoupler operates within its specified current limits, while additional components may be employed to filter noise and stabilize the circuit.

For optimal performance, it is crucial to select a triac that matches the load specifications, including voltage and current ratings, and to ensure that the optocoupler is capable of providing sufficient gate current to trigger the triac reliably. This configuration not only improves the reliability of the triac operation in low-temperature conditions but also enhances overall circuit safety and efficiency.This universal triac controller circuit with optocoupler solves the problem that triacs have when functioning at low temperatures (triac needs higher gate. 🔗 External reference