ve170 monitor repair with led

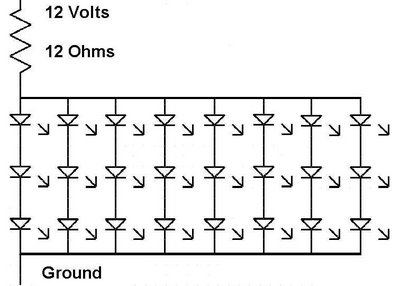

The issue with this monitor is that the power supply for the vacuum tube backlighting fails. The initial step involves completely disassembling the monitor into smaller components, followed by the careful removal of the gold-colored trays that hold the vacuum tubes. The tubes themselves must also be removed with caution to avoid breakage. The LEDs are positioned approximately 0.5 inches apart, utilizing the edge of a cardboard box as a reference. The test setup employed a 9-volt battery, with the LEDs spaced every three holes apart. The LEDs are wired in groups of three, each with a 12-ohm, 1-watt resistor in series with the sets. A resistor value between 10 ohms and 15 ohms would suffice. The LEDs in the tray must be angled at a 45-degree tilt towards the back of the screen for proper fitting, which is a tight arrangement. Attempts to use flat-front LEDs for direct upward illumination did not yield an increase in brightness. The bottom tray in the photo contains a total of 27 LEDs, with a similar quantity required in each tray. The dark areas in the image indicate the locations of the resistors, which are no longer placed in the tray for this reason. The labor involved in this process significantly exceeds the value of the repaired monitor. The image also illustrates that unless the LEDs are nearly touching, there will be gaps between them. An optimal solution would involve using surface-mount LEDs on a circuit board to ensure uniform lighting. A comparison with a laptop shows that the brightness is lower, and the color appears purple, despite appearing white to the naked eye, which suggests a bluish hue. The LEDs utilized were 3mm, 16,000 MCD bright white LEDs sourced from eBay. There are brighter alternatives available that may perform better. The flat-top LEDs fit better due to their shorter height and provide more even illumination across the screen. Additionally, resistors can be placed externally, wiring all LEDs in parallel in sets of three, with a 10 to 20-ohm resistor connected externally to the 12-volt power supply.

The described monitor repair process highlights the challenges associated with replacing the power supply for vacuum tube backlighting. The disassembly phase is critical, requiring meticulous handling to prevent damage to the vacuum tubes and their trays. The strategic placement of LEDs is essential for optimal light distribution, with the specified spacing and angling aimed at maximizing illumination efficiency.

The use of a 9-volt battery for testing demonstrates a practical approach to validating the LED configuration before final assembly. The choice of resistors is also pivotal, as they regulate current flow to the LEDs, ensuring they operate within safe limits while providing adequate brightness. The arrangement of LEDs in sets of three, with careful attention to their spacing, is necessary to avoid dark spots on the display.

For improved performance, the suggestion to utilize surface-mount LEDs on a dedicated circuit board represents a significant advancement in design. This approach would facilitate a more compact assembly and potentially enhance the uniformity of the backlighting across the screen. The comparison with laptop displays emphasizes the need for brightness and color accuracy in monitor design, as these factors are critical for user satisfaction.

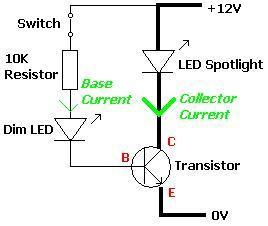

Future iterations of this project could explore the integration of higher-efficiency LEDs and alternative power supply solutions to further enhance the monitor's performance. Additionally, the implementation of a more sophisticated thermal management system may be beneficial, given the heat generated by high-brightness LEDs. Overall, the project illustrates the complexities of retrofitting older technology with modern lighting solutions, underscoring the balance between cost, labor, and performance.The problem with this monitor is that the power supply for the vacuum tube back lighting dies. The first step is to totally disassemble the monitor into little pieces, then carefully remove the gold colored trays that hold the vacuum tubes. Then carefully remove the tubes themselves without breaking them, like that can be done. The LED`s are spaced at about 1/2 inches apart by using the edge of a cardboard box as can be seen below. This was the test setup using a 9 volt battery, the LED`s are spaced every three holes from each other. The LED`s are wired in sets of 3 with a 12 ohm 1 watt resistor in series with all of the sets of three LED`s.

A 10 ohm to 15 ohm resistor would work just as well. This is what the LED`s look like in the tray. They have to be angled at a 45 degree angle towards the back of the screen in order to fit and it is a very tight fit. I tried to use a flat front LED so it could aim directly up at the screen but did not see any increase in brightness.

This is what it looks like with the bottom tray full of LED`s. There are a total of 27 LED`s in the bottom light tray in this photo. There needs to be about 27 LED`s in each of the trays. The dark areas are where the resistors are located. I no longer put any resistors in the tray for that reason. As you might be able to guess the labor far exceeds the value of the fixed monitor. Also you can see in the photo above that unless you space the LED`s so they are almost touching each other then there will be blank spaces between them. The ideal solution would be surface mount LED`s on a circuit board to provide continuous lighting. The picture below shows what it looks like compared to a laptop. As you can see it is not as bright and the picture has a purple color to it. Even thought the color looks white to the eye it is somewhat blue by comparison. The LED`s used were 3mm 16, 000 MCD bright white LED`s found on EBay. There are brighter LED`s available that might work even better. I tried using the flat top LED`s and they fit better because they are shorter and light the screen more evenly.

Also the resistors can be external, wire all of the LED`s up in parallel sets of 3 each, then use a 10 to 20 ohm resistor externally between it and the 12 volt power supply. 🔗 External reference

The described monitor repair process highlights the challenges associated with replacing the power supply for vacuum tube backlighting. The disassembly phase is critical, requiring meticulous handling to prevent damage to the vacuum tubes and their trays. The strategic placement of LEDs is essential for optimal light distribution, with the specified spacing and angling aimed at maximizing illumination efficiency.

The use of a 9-volt battery for testing demonstrates a practical approach to validating the LED configuration before final assembly. The choice of resistors is also pivotal, as they regulate current flow to the LEDs, ensuring they operate within safe limits while providing adequate brightness. The arrangement of LEDs in sets of three, with careful attention to their spacing, is necessary to avoid dark spots on the display.

For improved performance, the suggestion to utilize surface-mount LEDs on a dedicated circuit board represents a significant advancement in design. This approach would facilitate a more compact assembly and potentially enhance the uniformity of the backlighting across the screen. The comparison with laptop displays emphasizes the need for brightness and color accuracy in monitor design, as these factors are critical for user satisfaction.

Future iterations of this project could explore the integration of higher-efficiency LEDs and alternative power supply solutions to further enhance the monitor's performance. Additionally, the implementation of a more sophisticated thermal management system may be beneficial, given the heat generated by high-brightness LEDs. Overall, the project illustrates the complexities of retrofitting older technology with modern lighting solutions, underscoring the balance between cost, labor, and performance.The problem with this monitor is that the power supply for the vacuum tube back lighting dies. The first step is to totally disassemble the monitor into little pieces, then carefully remove the gold colored trays that hold the vacuum tubes. Then carefully remove the tubes themselves without breaking them, like that can be done. The LED`s are spaced at about 1/2 inches apart by using the edge of a cardboard box as can be seen below. This was the test setup using a 9 volt battery, the LED`s are spaced every three holes from each other. The LED`s are wired in sets of 3 with a 12 ohm 1 watt resistor in series with all of the sets of three LED`s.

A 10 ohm to 15 ohm resistor would work just as well. This is what the LED`s look like in the tray. They have to be angled at a 45 degree angle towards the back of the screen in order to fit and it is a very tight fit. I tried to use a flat front LED so it could aim directly up at the screen but did not see any increase in brightness.

This is what it looks like with the bottom tray full of LED`s. There are a total of 27 LED`s in the bottom light tray in this photo. There needs to be about 27 LED`s in each of the trays. The dark areas are where the resistors are located. I no longer put any resistors in the tray for that reason. As you might be able to guess the labor far exceeds the value of the fixed monitor. Also you can see in the photo above that unless you space the LED`s so they are almost touching each other then there will be blank spaces between them. The ideal solution would be surface mount LED`s on a circuit board to provide continuous lighting. The picture below shows what it looks like compared to a laptop. As you can see it is not as bright and the picture has a purple color to it. Even thought the color looks white to the eye it is somewhat blue by comparison. The LED`s used were 3mm 16, 000 MCD bright white LED`s found on EBay. There are brighter LED`s available that might work even better. I tried using the flat top LED`s and they fit better because they are shorter and light the screen more evenly.

Also the resistors can be external, wire all of the LED`s up in parallel sets of 3 each, then use a 10 to 20 ohm resistor externally between it and the 12 volt power supply. 🔗 External reference