Water Level Alarm

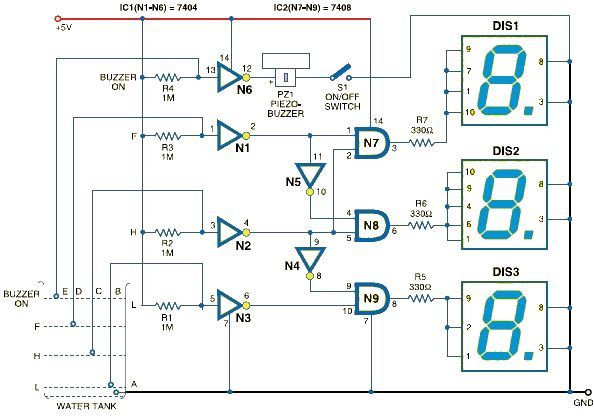

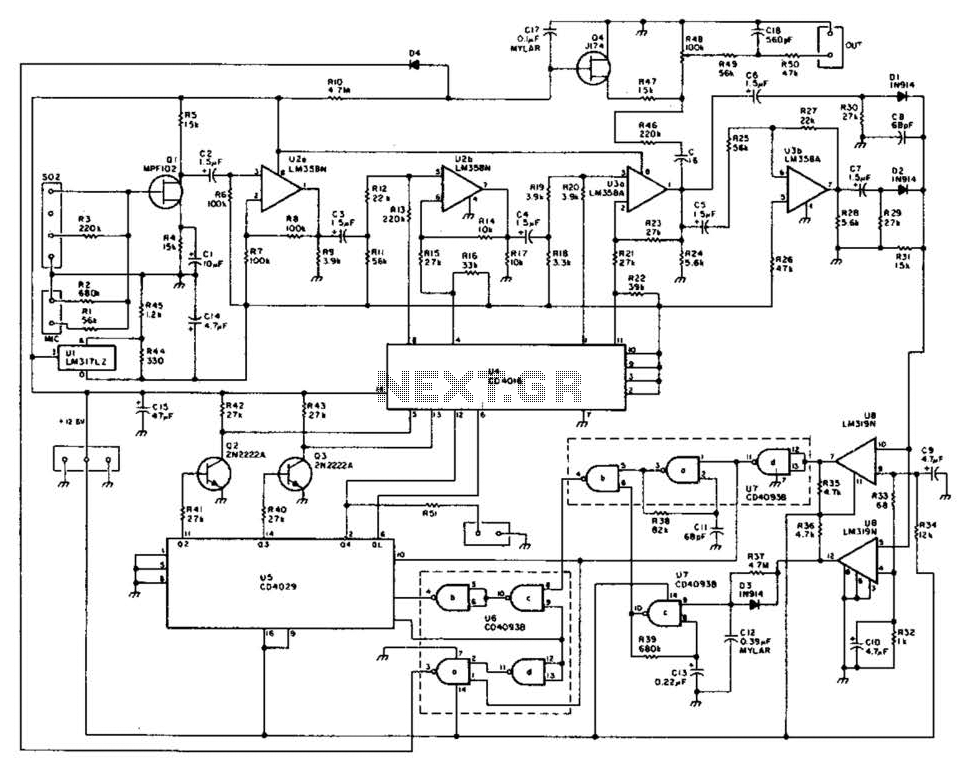

A circuit that offers visual indication of fluid level in a vessel, with a switchable audible alarm. Example uses would be to monitor the level of water in a bath or cold storage tank.

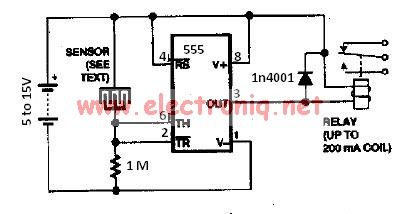

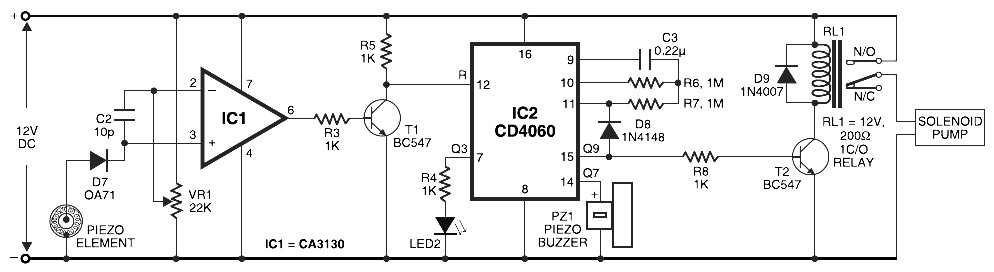

The described circuit functions as a fluid level monitoring system, capable of providing both visual and audible alerts to indicate the fluid level within a designated vessel. The primary components of this circuit typically include a fluid level sensor, an LED indicator, a microcontroller or comparator circuit, and a buzzer for the audible alarm.

The fluid level sensor can be a float switch, capacitive sensor, or ultrasonic sensor, depending on the application requirements. The float switch operates by rising and falling with the fluid level, completing a circuit when the fluid reaches a predetermined height. Capacitive sensors detect changes in capacitance caused by the presence of the fluid, while ultrasonic sensors use sound waves to measure the distance to the fluid surface.

The microcontroller or comparator circuit processes the input from the fluid level sensor. When the fluid level reaches a specified threshold, the microcontroller activates an LED indicator to provide a visual alert. This LED can be configured to illuminate in different colors to indicate various levels (e.g., green for safe levels, yellow for caution, and red for low levels).

In addition to the visual indicator, the circuit incorporates a switchable audible alarm. This alarm is typically a piezoelectric buzzer that emits sound when the fluid level is either too low or too high, depending on the design specifications. The switch mechanism allows users to activate or deactivate the alarm as needed, providing flexibility in monitoring applications.

Power supply considerations for the circuit should include voltage and current ratings that match the components used. A battery or an AC-to-DC power supply can be employed to ensure the circuit operates reliably.

Overall, this fluid level monitoring circuit is suitable for various applications, including domestic settings such as baths and aquariums, as well as industrial contexts like cold storage tanks, ensuring safe and efficient fluid management.A circuit that offers visual indication of fluid level in a vessel, with a switchable audible alarm. Example uses would be to monitor the level of water in a bath or cold storage tank. 🔗 External reference

The described circuit functions as a fluid level monitoring system, capable of providing both visual and audible alerts to indicate the fluid level within a designated vessel. The primary components of this circuit typically include a fluid level sensor, an LED indicator, a microcontroller or comparator circuit, and a buzzer for the audible alarm.

The fluid level sensor can be a float switch, capacitive sensor, or ultrasonic sensor, depending on the application requirements. The float switch operates by rising and falling with the fluid level, completing a circuit when the fluid reaches a predetermined height. Capacitive sensors detect changes in capacitance caused by the presence of the fluid, while ultrasonic sensors use sound waves to measure the distance to the fluid surface.

The microcontroller or comparator circuit processes the input from the fluid level sensor. When the fluid level reaches a specified threshold, the microcontroller activates an LED indicator to provide a visual alert. This LED can be configured to illuminate in different colors to indicate various levels (e.g., green for safe levels, yellow for caution, and red for low levels).

In addition to the visual indicator, the circuit incorporates a switchable audible alarm. This alarm is typically a piezoelectric buzzer that emits sound when the fluid level is either too low or too high, depending on the design specifications. The switch mechanism allows users to activate or deactivate the alarm as needed, providing flexibility in monitoring applications.

Power supply considerations for the circuit should include voltage and current ratings that match the components used. A battery or an AC-to-DC power supply can be employed to ensure the circuit operates reliably.

Overall, this fluid level monitoring circuit is suitable for various applications, including domestic settings such as baths and aquariums, as well as industrial contexts like cold storage tanks, ensuring safe and efficient fluid management.A circuit that offers visual indication of fluid level in a vessel, with a switchable audible alarm. Example uses would be to monitor the level of water in a bath or cold storage tank. 🔗 External reference