Water Level controller

The microcontroller-based water level controller and motor protector manages the on and off states of the motor based on the water level in the overhead tank (OHT). It regulates the tank's water level through a microcontroller, thereby providing automatic protection for the motor.

The microcontroller-based water level controller and motor protector is an essential system designed to maintain optimal water levels in an overhead tank while simultaneously safeguarding the motor from damage due to dry running or overflow conditions. The core component of this system is a microcontroller, which processes input from water level sensors and executes control logic to manage the motor operation.

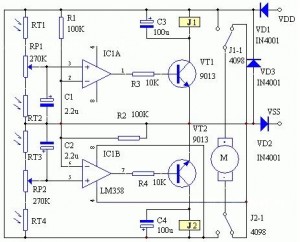

The system typically employs two types of sensors: a low-level sensor and a high-level sensor. The low-level sensor detects when the water level falls below a predefined threshold, signaling the microcontroller to activate the motor and fill the tank. Conversely, the high-level sensor indicates when the water level has reached its maximum capacity, prompting the microcontroller to turn off the motor to prevent overflow.

The microcontroller is programmed with specific algorithms that allow it to interpret the signals from the sensors. This includes debouncing logic to prevent false triggering from sensor noise and timing functions to manage the motor's on/off cycles effectively. Additionally, the microcontroller may include protection features such as a delay mechanism to prevent rapid cycling of the motor, which could lead to mechanical wear.

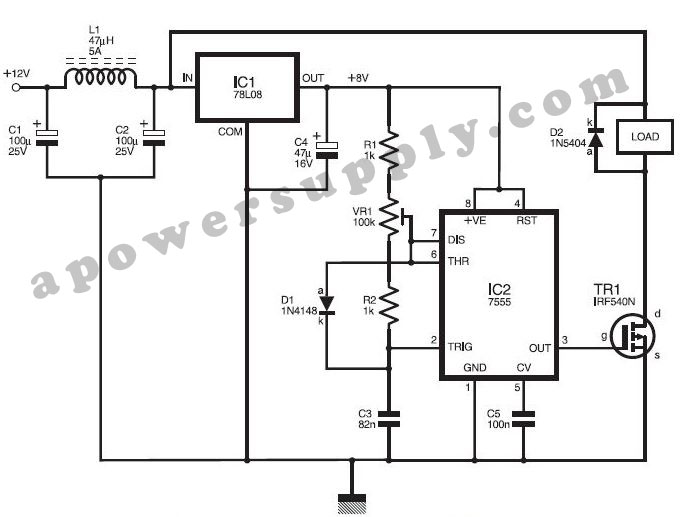

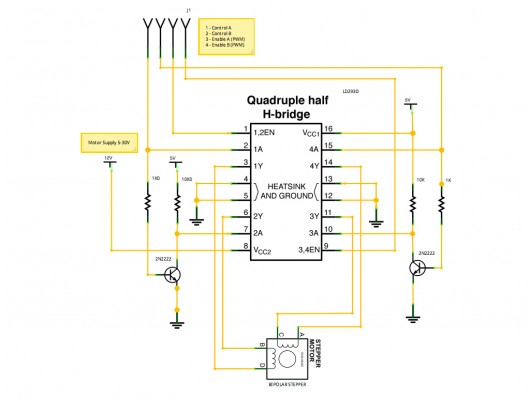

The output stage of the microcontroller typically interfaces with a relay or a solid-state switch that controls the motor's power supply. This ensures that the motor operates only when necessary, enhancing energy efficiency and prolonging the motor's lifespan.

In summary, the microcontroller-based water level controller cum motor protector is a sophisticated solution for managing water levels in overhead tanks, offering both operational efficiency and protection for the motor through automated control mechanisms.The Microcontroller based Water Level Controller cum Motor Protector controls on and off conditions of the motor depending upon the level of water in the over head tank (OHT), It controls water level of tank through micro-controller so that automatically protect the motor. ","0", 🔗 External reference

The microcontroller-based water level controller and motor protector is an essential system designed to maintain optimal water levels in an overhead tank while simultaneously safeguarding the motor from damage due to dry running or overflow conditions. The core component of this system is a microcontroller, which processes input from water level sensors and executes control logic to manage the motor operation.

The system typically employs two types of sensors: a low-level sensor and a high-level sensor. The low-level sensor detects when the water level falls below a predefined threshold, signaling the microcontroller to activate the motor and fill the tank. Conversely, the high-level sensor indicates when the water level has reached its maximum capacity, prompting the microcontroller to turn off the motor to prevent overflow.

The microcontroller is programmed with specific algorithms that allow it to interpret the signals from the sensors. This includes debouncing logic to prevent false triggering from sensor noise and timing functions to manage the motor's on/off cycles effectively. Additionally, the microcontroller may include protection features such as a delay mechanism to prevent rapid cycling of the motor, which could lead to mechanical wear.

The output stage of the microcontroller typically interfaces with a relay or a solid-state switch that controls the motor's power supply. This ensures that the motor operates only when necessary, enhancing energy efficiency and prolonging the motor's lifespan.

In summary, the microcontroller-based water level controller cum motor protector is a sophisticated solution for managing water levels in overhead tanks, offering both operational efficiency and protection for the motor through automated control mechanisms.The Microcontroller based Water Level Controller cum Motor Protector controls on and off conditions of the motor depending upon the level of water in the over head tank (OHT), It controls water level of tank through micro-controller so that automatically protect the motor. ","0", 🔗 External reference