When page is bookmarked text here is referenced verbatim

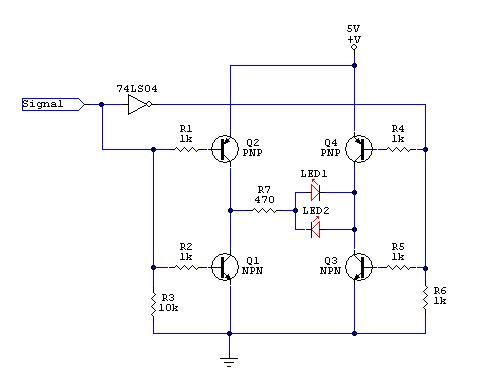

The image shows a completed locked anti-phase motor controller built on a breadboard, utilizing general-purpose transistors to control small DC motors for robotics applications. A typical DC motor controller lacks a braking function, which is essential for precise control. Addressing this issue is crucial as accurate motor control is necessary in robotics, particularly when cost is a consideration. DC motors are relatively inexpensive compared to other motor types, depending on their size. This tutorial provides guidance on breadboarding the motor controller hardware and programming the Netburner to output the locked anti-phase PWM signal. The entire process takes approximately three hours. The tutorial aims to use the Embedded Netburner MOD5213 to control a DC motor for small robotics applications. It is assumed that readers possess the following background and interests: If a computer lacks a 9-pin RS-232 Serial port, a USB adapter will need to be purchased, readily available online or in local computer stores. Before starting the motor controller project, several fundamental concepts must be addressed, including the function of an H-Bridge and the operation of a locked anti-phase motor driver. An H-Bridge is a basic motor controller configuration involving four transistors that allow for full forward and reverse motor operation. To drive the motor forward, transistors Q1 and Q3 must be activated while Q2 and Q4 remain off. Conversely, to reverse the motor, Q2 and Q4 are activated, while Q1 and Q3 are off, enabling complete power reversal through the motor. It is important to note that an invalid condition occurs when all transistors are activated, leading to a bypass of the motor and potentially causing a significant current spike that could damage the transistors. The locked anti-phase motor controller prevents this invalid condition through the use of an inverter. This inverter technique ensures that only one diagonal set of transistors conducts at any time, preventing all four transistors from being on simultaneously. The motor's operation is governed by the difference in time between high and low pulse durations in the duty cycle rather than the duty cycle itself. When the input signal is low, the motor spins at full throttle in one direction, while a high signal causes it to spin in the opposite direction. A 50% duty cycle results in no motor rotation, assuming a sufficiently high PWM frequency (>20 kHz). However, a drawback of this circuit type is that current continues to flow through the motor even when it is not rotating, which can impact efficiency and battery life. This section includes step-by-step instructions and photos for building the PWM motor driver, along with a schematic for constructing the locked anti-phase motor controller. This transistor motor driver can handle motors with a current draw of up to approximately 500 mA. The transistors used are not recommended for practical applications, but they illustrate the concept by utilizing LEDs wired in reverse polarity (a bi-color LED). For further information on the specific motor controller theory, refer to the provided web page. The motor controller circuit has been enhanced for better robustness concerning the PWM output from the Netburner. Using the accompanying schematic diagram, the circuit should be built on a breadboard using solid core wires to connect all components, sharing some of the traces.

The locked anti-phase motor controller circuit is an essential component for applications requiring precise motor control, particularly in robotics. The use of general-purpose transistors allows for a cost-effective solution while maintaining the necessary functionality. The H-Bridge configuration is critical, as it enables bidirectional control of the motor. In this setup, the transistors are strategically activated to ensure that only one pair of transistors conducts at a time, preventing the invalid condition that could lead to damage.

When implementing this circuit, attention must be paid to the PWM frequency and duty cycle to achieve the desired motor speed and direction. The choice of transistors should be made carefully, considering their current ratings and switching capabilities to ensure reliable operation. Additionally, the use of an inverter in the design enhances safety by preventing simultaneous conduction of all transistors, thereby protecting the circuit from potential failures.

The tutorial serves as a practical guide for building the motor controller on a breadboard, with clear instructions and visual aids to facilitate the assembly process. It is important to follow the schematic closely and verify connections to ensure proper functionality. The enhancements made to the circuit design aim to improve performance and reliability, making it suitable for various robotics applications. Overall, this locked anti-phase motor controller represents a valuable tool for hobbyists and engineers working with small DC motors in robotic systems.The photo depicts a completed (bread-barded) locked anti-phase motor controller using general purpose transistors, which allows you to control small DC motors for robotics applications. The big picture problem is that a normal DC motor controller does not have the "braking" function, which allows for precise control.

Solving this partially or comp letely is important because precise motor control is needed in robotics applications, and where cost is a factor. A DC motor is fairly cheap, dependent on size, compared to other types of motors. This tutorial shows you how to bread-board the motor controller hardware, and program the Netburner to output the lcked anti-phase PWM.

It takes approximately 3 hours to complete. This tutorial`s motivation is to use the Embedded Netburner MOD5213 to control a DC motor for small robotics applications. Readers of this tutorial assumes the reader has the following background and interests: *If your computer does not have a 9 pin RS-232 Serial port, you will need to purchase a USB Adapter.

They can be found almost anywhere on the internet, or in a computer store near you. Before we actually begin the motor controller, there are a few things that need to be addressed first. What is an H-Bridge, and what does it do (and) What is a locked anti-phase motor driver, and how does it work First of all, an H-bridge is a basic motor controller in which 4 transistors are configured with a motor to allow full forward and reverse of the motor, rather than just one direction.

As you can see in the figure below, how the motor controller gets its name. In order to drive the motor forward, transistors Q1 and Q3 must be driven (while Q2 and 4 are OFF). To drive the motor in reverse, Q2 and 4 should be driven, while Q1 and Q3 should remain off. This allows for the full reversal of power through the motor. NOTE! There is an invalid condition where all the transistors are driven, and in that case, the motor is bypassed, and a huge current spike will go through the transistors, possibly blowing them up (or at least permanently damaging them). With the locked anti-phase motor controller, this invalid condition is never satisfied because of an inverter.

The next question deals with the concept of controlling the motor using the inverter technique on the h-bridge. With having the inverter on the signal, only one diagonal set of transistors can conduct at any given time, thus all 4 transistors will usually never be on.

The motor is driven by a difference in the time high vs. time low pulse in the duty cycle, rather than the duty cycle all together. When the input signal is low, the motor spins full throttle in one direction, and when the signal is high, spins full throttle the opposite direction. When a 50% duty cycle is given as a signal, the difference of the time high vs. time low is zero, so there is no motor rotation (assuming the PWM is a fairly high frequency >20kHz).

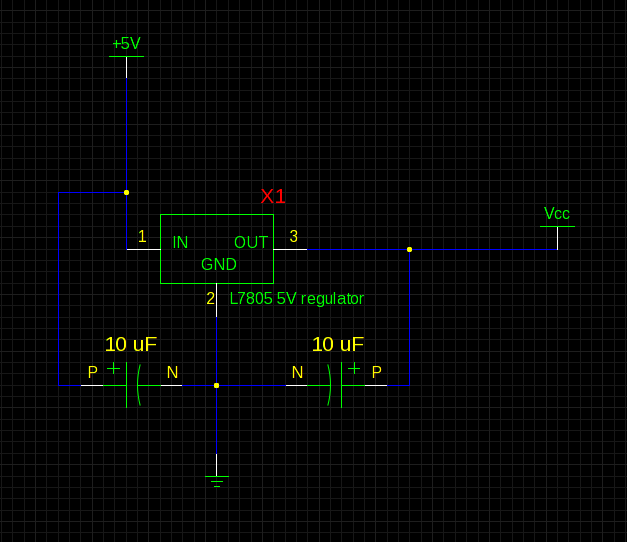

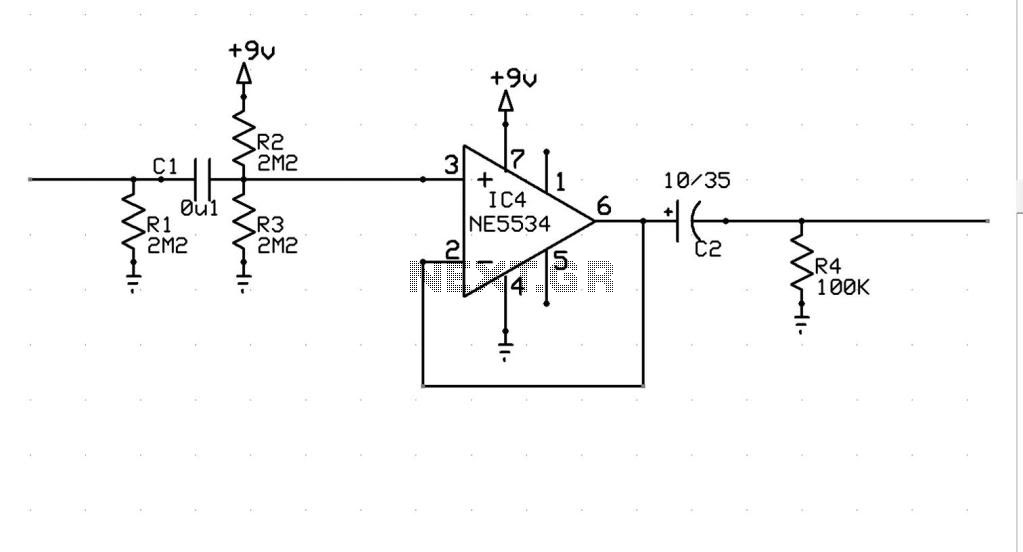

There are some downsides to using this circuit type for robotics. The main drawback is that even when the motor is not rotating, current is still being drawn through the motor, which may pose a problem when working with efficiency and battery life. This section gives step-by-step instructions along with photos to build the PWM motor driver. A schematic to construct the locked anti-phase motor controller is shown below. This transistor motor driver will drive motors up to around 500mA current draw. Using these transistors is not recommended, but is used to show the concept by using LED`s wired up in reverse polarity (a bi-color LED).

for more information on the specific motor controller theory, refer to this web page:. I enhanced the motor controller circuit a little to make it more robust to the PWM output from the Netburner. Using the schematic diagram below, construct the circuit on a breadboard. I used solid core wires to connect all the components, along with sharing some of the trac 🔗 External reference

The locked anti-phase motor controller circuit is an essential component for applications requiring precise motor control, particularly in robotics. The use of general-purpose transistors allows for a cost-effective solution while maintaining the necessary functionality. The H-Bridge configuration is critical, as it enables bidirectional control of the motor. In this setup, the transistors are strategically activated to ensure that only one pair of transistors conducts at a time, preventing the invalid condition that could lead to damage.

When implementing this circuit, attention must be paid to the PWM frequency and duty cycle to achieve the desired motor speed and direction. The choice of transistors should be made carefully, considering their current ratings and switching capabilities to ensure reliable operation. Additionally, the use of an inverter in the design enhances safety by preventing simultaneous conduction of all transistors, thereby protecting the circuit from potential failures.

The tutorial serves as a practical guide for building the motor controller on a breadboard, with clear instructions and visual aids to facilitate the assembly process. It is important to follow the schematic closely and verify connections to ensure proper functionality. The enhancements made to the circuit design aim to improve performance and reliability, making it suitable for various robotics applications. Overall, this locked anti-phase motor controller represents a valuable tool for hobbyists and engineers working with small DC motors in robotic systems.The photo depicts a completed (bread-barded) locked anti-phase motor controller using general purpose transistors, which allows you to control small DC motors for robotics applications. The big picture problem is that a normal DC motor controller does not have the "braking" function, which allows for precise control.

Solving this partially or comp letely is important because precise motor control is needed in robotics applications, and where cost is a factor. A DC motor is fairly cheap, dependent on size, compared to other types of motors. This tutorial shows you how to bread-board the motor controller hardware, and program the Netburner to output the lcked anti-phase PWM.

It takes approximately 3 hours to complete. This tutorial`s motivation is to use the Embedded Netburner MOD5213 to control a DC motor for small robotics applications. Readers of this tutorial assumes the reader has the following background and interests: *If your computer does not have a 9 pin RS-232 Serial port, you will need to purchase a USB Adapter.

They can be found almost anywhere on the internet, or in a computer store near you. Before we actually begin the motor controller, there are a few things that need to be addressed first. What is an H-Bridge, and what does it do (and) What is a locked anti-phase motor driver, and how does it work First of all, an H-bridge is a basic motor controller in which 4 transistors are configured with a motor to allow full forward and reverse of the motor, rather than just one direction.

As you can see in the figure below, how the motor controller gets its name. In order to drive the motor forward, transistors Q1 and Q3 must be driven (while Q2 and 4 are OFF). To drive the motor in reverse, Q2 and 4 should be driven, while Q1 and Q3 should remain off. This allows for the full reversal of power through the motor. NOTE! There is an invalid condition where all the transistors are driven, and in that case, the motor is bypassed, and a huge current spike will go through the transistors, possibly blowing them up (or at least permanently damaging them). With the locked anti-phase motor controller, this invalid condition is never satisfied because of an inverter.

The next question deals with the concept of controlling the motor using the inverter technique on the h-bridge. With having the inverter on the signal, only one diagonal set of transistors can conduct at any given time, thus all 4 transistors will usually never be on.

The motor is driven by a difference in the time high vs. time low pulse in the duty cycle, rather than the duty cycle all together. When the input signal is low, the motor spins full throttle in one direction, and when the signal is high, spins full throttle the opposite direction. When a 50% duty cycle is given as a signal, the difference of the time high vs. time low is zero, so there is no motor rotation (assuming the PWM is a fairly high frequency >20kHz).

There are some downsides to using this circuit type for robotics. The main drawback is that even when the motor is not rotating, current is still being drawn through the motor, which may pose a problem when working with efficiency and battery life. This section gives step-by-step instructions along with photos to build the PWM motor driver. A schematic to construct the locked anti-phase motor controller is shown below. This transistor motor driver will drive motors up to around 500mA current draw. Using these transistors is not recommended, but is used to show the concept by using LED`s wired up in reverse polarity (a bi-color LED).

for more information on the specific motor controller theory, refer to this web page:. I enhanced the motor controller circuit a little to make it more robust to the PWM output from the Netburner. Using the schematic diagram below, construct the circuit on a breadboard. I used solid core wires to connect all the components, along with sharing some of the trac 🔗 External reference