Wiper speed controller

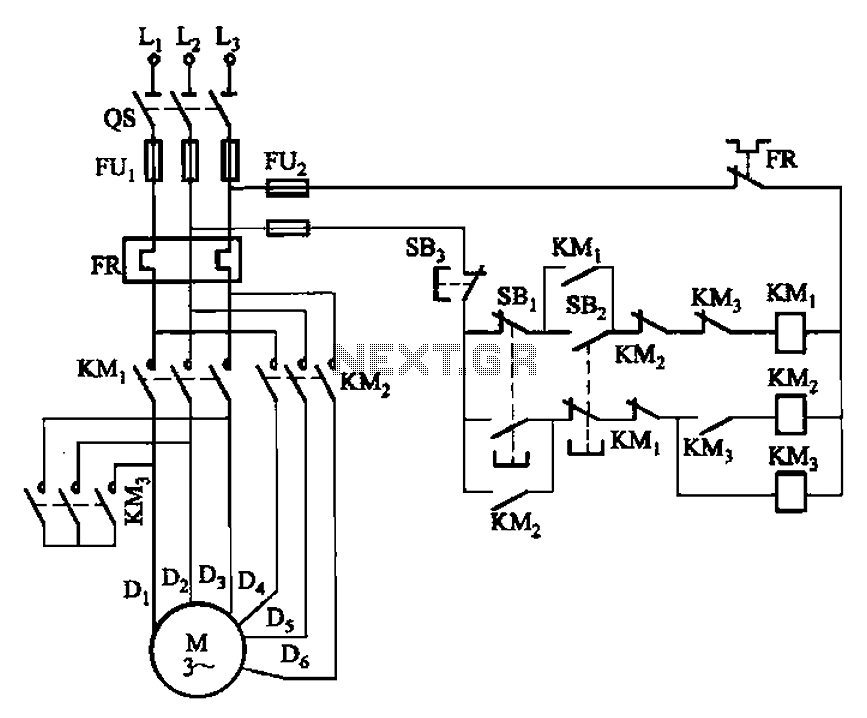

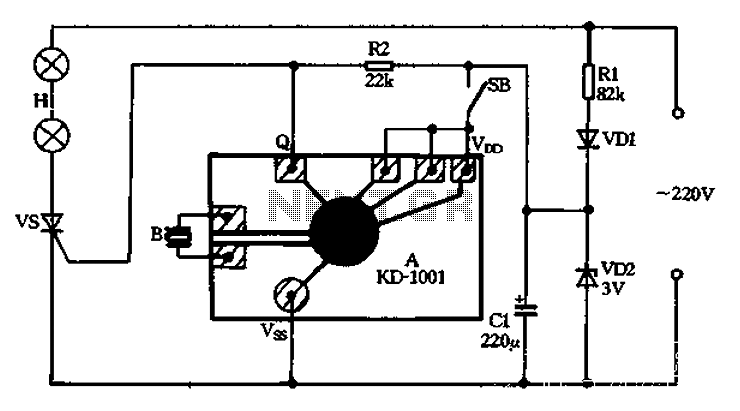

The relay that supplies power to the wiper motor is activated at regular intervals by the timer circuit, which closes the contacts for the wiper motor. Potentiometer R1 functions as the pulse rate control, while potentiometer R5 is used for pulse width control. These two controls should be fine-tuned for optimal performance once the unit is installed in a vehicle.

The described circuit utilizes a relay to manage the power distribution to the wiper motor, facilitating its operation in a controlled manner. The timer circuit plays a crucial role in this setup, generating periodic signals that actuate the relay. When the relay is energized, it closes the contacts, allowing current to flow to the wiper motor, thus initiating its movement.

Potentiometer R1 is integrated into the circuit to adjust the pulse rate, which determines how frequently the wiper motor operates. By varying the resistance of R1, the time interval between each activation of the motor can be modified, allowing for customization based on environmental conditions such as rain intensity.

Potentiometer R5, on the other hand, is responsible for controlling the pulse width. This adjustment influences the duration for which the wiper motor remains active during each cycle. A longer pulse width will result in extended wiper operation, while a shorter pulse width will decrease the active time.

It is essential to calibrate both potentiometers after installation in a vehicle to ensure optimal wiper performance. This adjustment allows the user to tailor the wiper's operation to specific needs, enhancing visibility and safety during inclement weather. Proper tuning of these parameters contributes significantly to the efficiency and effectiveness of the wiper system.

The overall design emphasizes user control and adaptability, making it suitable for various driving conditions. The relay, timer circuit, and adjustable potentiometers work in harmony to provide a reliable and efficient wiper motor operation.The relay which applies power to the wiper motor is actuated at periodic intervals by the timer circuit, closing the wiper motor contacts. Potentiometer R1 serves as the pulse rate control and potentiometer R5 as the pulse width control. These two controls should be adjusted for optimum performance after the unit is installed in a car.

The described circuit utilizes a relay to manage the power distribution to the wiper motor, facilitating its operation in a controlled manner. The timer circuit plays a crucial role in this setup, generating periodic signals that actuate the relay. When the relay is energized, it closes the contacts, allowing current to flow to the wiper motor, thus initiating its movement.

Potentiometer R1 is integrated into the circuit to adjust the pulse rate, which determines how frequently the wiper motor operates. By varying the resistance of R1, the time interval between each activation of the motor can be modified, allowing for customization based on environmental conditions such as rain intensity.

Potentiometer R5, on the other hand, is responsible for controlling the pulse width. This adjustment influences the duration for which the wiper motor remains active during each cycle. A longer pulse width will result in extended wiper operation, while a shorter pulse width will decrease the active time.

It is essential to calibrate both potentiometers after installation in a vehicle to ensure optimal wiper performance. This adjustment allows the user to tailor the wiper's operation to specific needs, enhancing visibility and safety during inclement weather. Proper tuning of these parameters contributes significantly to the efficiency and effectiveness of the wiper system.

The overall design emphasizes user control and adaptability, making it suitable for various driving conditions. The relay, timer circuit, and adjustable potentiometers work in harmony to provide a reliable and efficient wiper motor operation.The relay which applies power to the wiper motor is actuated at periodic intervals by the timer circuit, closing the wiper motor contacts. Potentiometer R1 serves as the pulse rate control and potentiometer R5 as the pulse width control. These two controls should be adjusted for optimum performance after the unit is installed in a car.