Wireless On-Off Switch

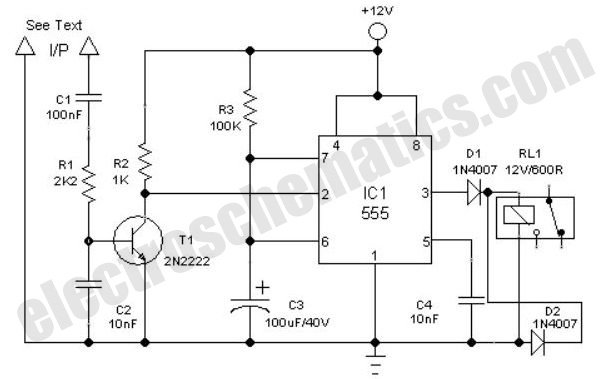

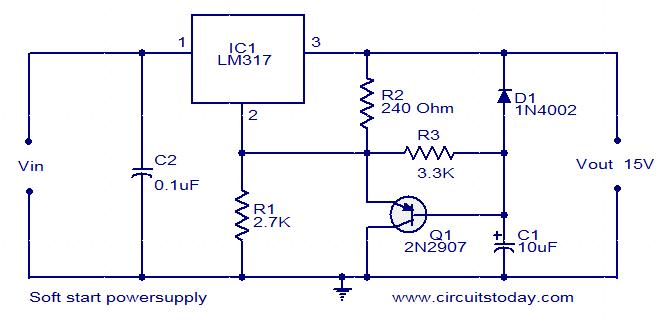

Typically, home appliances are controlled using switches, sensors, and similar devices. However, physical contact with switches can pose risks, especially in the event of a short circuit. The circuit outlined here eliminates the need for physical contact to operate the appliance. It requires only the movement of a hand between the infrared LED (D2) and the phototransistor (Q1). The infrared rays emitted by D2 are detected by the phototransistor, which activates devices such as hidden locks, flush systems, or hand dryers. This circuit is notably stable and sensitive in comparison to other AC appliance control systems. It is designed to be simple, compact, and cost-effective, with low current consumption measured in milliamperes. The circuit utilizes an IC CA3140, along with D2, a phototransistor, and various discrete components. When a regulated 5V power supply is connected, D2 emits infrared rays that are detected by Q1, provided they are correctly aligned. The collector of Q1 connects to the non-inverting pin (3) of IC1, while the inverting pin (2) is linked to a voltage-divider preset (R4). Adjusting preset R4 allows for variation in the reference voltage at pin 2, which influences the sensitivity of the phototransistor. The operational amplifier IC1 amplifies the signal received from the phototransistor. Resistor R3 regulates the base current of the transistor BC548 (Q2). The high output from IC1 at pin 6 activates the transistor Q2, which in turn energizes relay RL1 to power the appliance, such as a hand dryer, through the relay contacts. The operation of the circuit is straightforward; to switch on the appliance, one simply interrupts the infrared rays reaching the phototransistor with their hand. While the infrared beam is interrupted, the appliance remains powered through the relay. Removing the hand from the infrared beam deactivates the appliance via the relay. The circuit should be assembled on a general-purpose PCB. Resistors can be identified using color coding or a multimeter. It is essential to check the polarity and pin configuration of the IC before mounting it in its base. After soldering the components, connect a +5V supply to the circuit.

This infrared-based control circuit is an innovative solution for managing home appliances without direct contact, enhancing safety and convenience. The use of an infrared LED and phototransistor combination provides a non-invasive means of activation that significantly reduces the risk of electrical hazards associated with traditional switch-based systems. The CA3140 operational amplifier serves as the core component for signal amplification, ensuring that even minimal interruptions in the infrared beam can effectively trigger the control mechanism.

The design's sensitivity can be fine-tuned through the voltage-divider preset, allowing for customization based on the specific requirements of the application or the environment in which the circuit operates. This feature makes the circuit adaptable for various scenarios, whether in residential settings or commercial applications where hygiene and safety are paramount.

The relay (RL1) acts as a switch that can handle higher loads, making it suitable for controlling various appliances, including those that require significant power, such as hand dryers or automatic flush systems. The low current consumption of the circuit also contributes to energy efficiency, making it an environmentally friendly option for modern homes.

In terms of assembly, careful attention should be paid to the layout on the PCB to minimize interference and ensure reliable operation. Proper identification of components and verification of connections is crucial to prevent malfunctions. Overall, this circuit exemplifies a modern approach to appliance control, combining safety, efficiency, and ease of use in a compact design.Normally home appliances are controlled by means of switches, sensors, etc. However, physical contact with switches may be dangerous if there is any shorting. The circuit described here requires no physical contact for operating the appliance. You just need to move your hand between the infrared LED (D2) and the phototransistor (Q1). The infrared rays transmitted by D2 is detected by the phototransistor to activate the hidden lock, flush system, hand dryer or else. This circuit is very stable and sensitive compared to other AC appliance control circuits. It is simple, compact and cheap. Current consumption is low in milliamperes. The circuit is built around an IC CA3140, D2, phototransistor and other discrete components. When regulated 5V is connected to the circuit, D2 emits infrared rays, which are received by phototransistor Q1 if it is properly aligned.

The collector of Q1 is connected to non-inverting pin 3 of IC1. Inverting pin 2 of IC1 is connected to voltage-divider preset R4. Using preset R4 you can vary the reference voltage at pin 2, which also affects sensitivity of the phototransistor. Op-amp IC1 amplifies the signal received from the phototransistor. Resistor R3 controls the base current of transistor BC548 (Q2). The high output of IC1 at pin 6 drives transistor Q2 to energies relay RL1 and switch on the appliance, say, hand dryer, through the relay contacts.

The working of the circuit is simple. In order to switch on the appliance, you simply interrupt the infrared rays falling on the phototransistor through your hand. During the interruption, the appliance remains on through the relay. When you remove your hand from the infrared beam, the appliance turns off through the relay. Assemble the circuit on any general-purpose PCB. Identify the resistors through colour coding or using the multimeter. Check the polarity and pin configuration of the IC and mount it using base. After soldering the circuit, connect +5V supply to the circuit. 🔗 External reference

This infrared-based control circuit is an innovative solution for managing home appliances without direct contact, enhancing safety and convenience. The use of an infrared LED and phototransistor combination provides a non-invasive means of activation that significantly reduces the risk of electrical hazards associated with traditional switch-based systems. The CA3140 operational amplifier serves as the core component for signal amplification, ensuring that even minimal interruptions in the infrared beam can effectively trigger the control mechanism.

The design's sensitivity can be fine-tuned through the voltage-divider preset, allowing for customization based on the specific requirements of the application or the environment in which the circuit operates. This feature makes the circuit adaptable for various scenarios, whether in residential settings or commercial applications where hygiene and safety are paramount.

The relay (RL1) acts as a switch that can handle higher loads, making it suitable for controlling various appliances, including those that require significant power, such as hand dryers or automatic flush systems. The low current consumption of the circuit also contributes to energy efficiency, making it an environmentally friendly option for modern homes.

In terms of assembly, careful attention should be paid to the layout on the PCB to minimize interference and ensure reliable operation. Proper identification of components and verification of connections is crucial to prevent malfunctions. Overall, this circuit exemplifies a modern approach to appliance control, combining safety, efficiency, and ease of use in a compact design.Normally home appliances are controlled by means of switches, sensors, etc. However, physical contact with switches may be dangerous if there is any shorting. The circuit described here requires no physical contact for operating the appliance. You just need to move your hand between the infrared LED (D2) and the phototransistor (Q1). The infrared rays transmitted by D2 is detected by the phototransistor to activate the hidden lock, flush system, hand dryer or else. This circuit is very stable and sensitive compared to other AC appliance control circuits. It is simple, compact and cheap. Current consumption is low in milliamperes. The circuit is built around an IC CA3140, D2, phototransistor and other discrete components. When regulated 5V is connected to the circuit, D2 emits infrared rays, which are received by phototransistor Q1 if it is properly aligned.

The collector of Q1 is connected to non-inverting pin 3 of IC1. Inverting pin 2 of IC1 is connected to voltage-divider preset R4. Using preset R4 you can vary the reference voltage at pin 2, which also affects sensitivity of the phototransistor. Op-amp IC1 amplifies the signal received from the phototransistor. Resistor R3 controls the base current of transistor BC548 (Q2). The high output of IC1 at pin 6 drives transistor Q2 to energies relay RL1 and switch on the appliance, say, hand dryer, through the relay contacts.

The working of the circuit is simple. In order to switch on the appliance, you simply interrupt the infrared rays falling on the phototransistor through your hand. During the interruption, the appliance remains on through the relay. When you remove your hand from the infrared beam, the appliance turns off through the relay. Assemble the circuit on any general-purpose PCB. Identify the resistors through colour coding or using the multimeter. Check the polarity and pin configuration of the IC and mount it using base. After soldering the circuit, connect +5V supply to the circuit. 🔗 External reference