12ft GPS Wall Clock

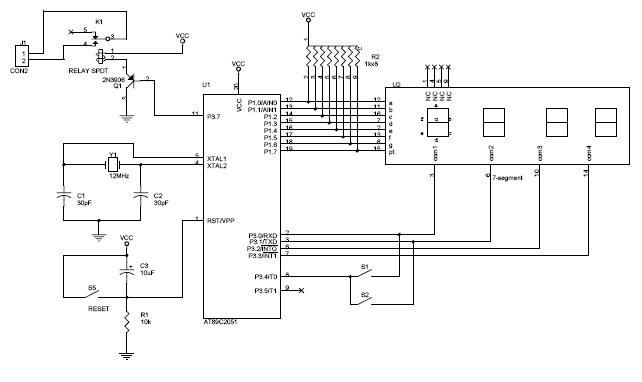

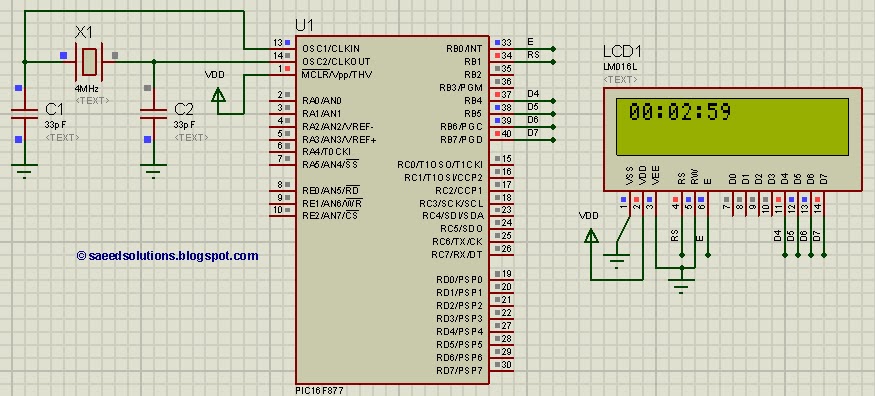

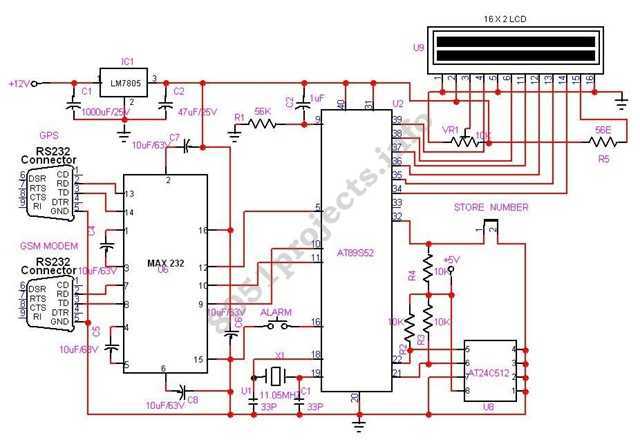

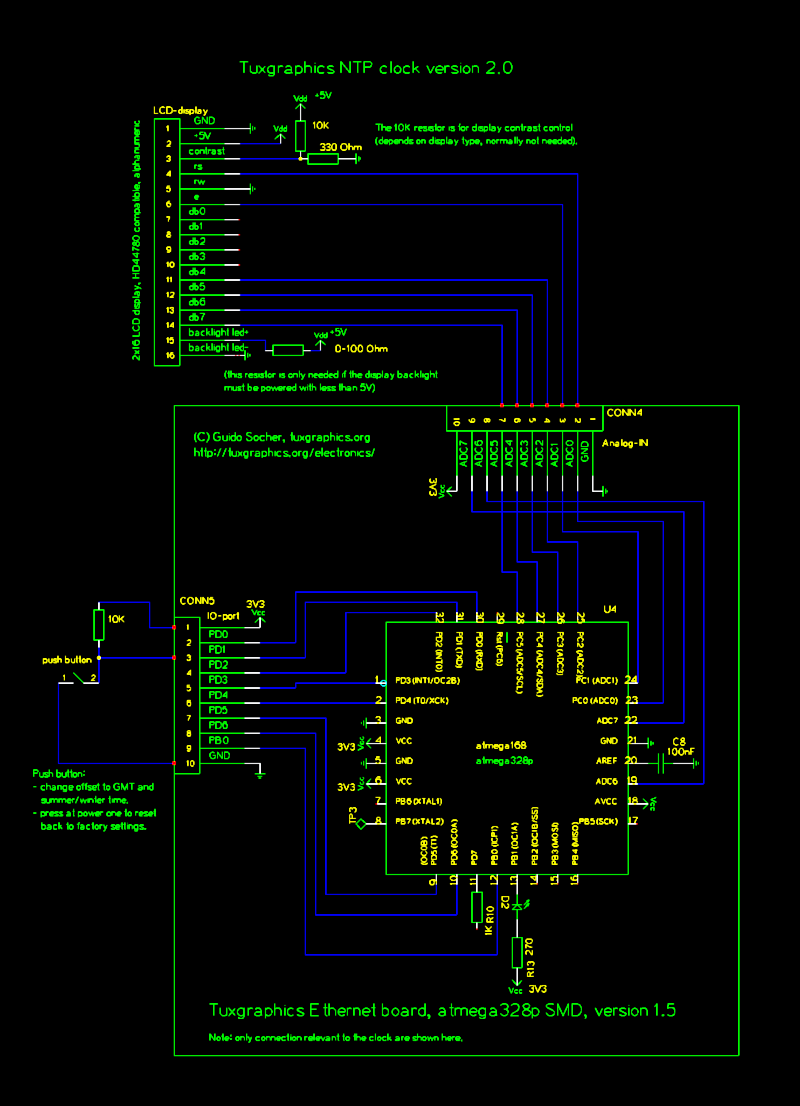

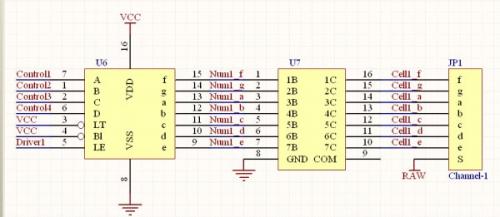

A discussion was held regarding the creation of a 6-foot tall alarm clock, modeled after a Timex faceplate. Initially perceived as an impractical idea, the project faced challenges that led to its suspension. However, the discovery of pre-packaged LED light bars reignited interest in constructing a large clock, which ultimately grew to a height of 12 feet. The clock now incorporates a GPS receiver, allowing it to automatically set itself and display hours, minutes, and seconds with an accuracy of 100 nanoseconds. The LED light bars, which consist of three LEDs and operate on 12V, come with built-in current limiting resistors and plastic carriers, facilitating the assembly of extensive arrays of bright LEDs without the need for custom configurations. Each bar consumes approximately 30mA at 12V, which is efficient compared to traditional neon tubes. The clock features two colons and six digits, drawing a total of 2.76 Amps, equating to around 33 Watts of power. An ATX power supply was considered, but a Mastech HY1803D variable bench power supply was utilized, capable of supplying 12V at 3A. Initially, the light bars were to be mounted directly to the wall in a 7-segment digit configuration, but the intense LED brightness necessitated a diffusion solution. A Styrene sheet was chosen to mitigate the harsh LED spots, requiring it to be positioned about 2 inches away from the LEDs. To further enhance light diffusion, 1.5-inch Styrofoam sheets were used to create light boxes around each set of light bars. The digits were designed to be 24 inches tall, and a multi-sheet printout method was employed to create stencils for the segments. The decision was made to construct the clock with separate digits for ease of manufacturing and improved aesthetics. This design choice also simplified wiring, as each digit required only seven signal wires and one return wire, leading to the use of pre-terminated Cat5 cables for connections. A master foam-board stencil was later created to ensure better alignment of the digit layers.

The 12-foot tall clock project showcases an innovative approach to large-scale LED display design. The integration of GPS technology for automatic time-setting enhances the functionality of the clock, making it not only visually striking but also precise. The use of pre-packaged LED light bars significantly reduces the complexity and labor involved in creating a large LED display, as they are designed for easy assembly and operation. The choice of 12V operation is standard in many LED applications, providing a balance between brightness and energy efficiency.

The decision to diffuse the intense LED light is critical to creating a visually appealing display. The Styrene and Styrofoam light boxes effectively minimize hot spots and provide a uniform light distribution across the digits, enhancing readability from a distance. This is particularly important for a clock of this size, where visibility is paramount.

The construction method, which involves creating separate digits, not only simplifies the manufacturing process but also allows for modularity in design. Each digit can be produced independently, enabling easier repairs or replacements if necessary. The use of Cat5 cables for wiring is a practical solution, leveraging existing technology to facilitate connections while maintaining a tidy and organized appearance.

Overall, this project exemplifies the intersection of creativity and engineering, resulting in a large-scale, functional art piece that effectively utilizes modern LED technology and design principles. The thoughtful consideration of materials, methods, and technologies involved in the clock’s construction contributes to its success as both a timekeeping device and a striking visual installation.We discussed creating a 6` tall alarm clock - authentic down to the Timex face plate. While this may sound like a silly idea to begin with, it quickly became obvious just how difficult it would be to build at that scale so the project was scuttled. Recently, I came across a source for pre-package LED light bars that rejuvenated my need for a big clock. Why not So here is the little project that grew to 12 feet. We added a GPS receiver so now we have a 12` clock that sets itself, displays hours/minutes/seconds, and is accurate to 100ns. Beat that bed side alarm! These light bars, as I like to call them, use three LEDs and run on 12V. Why use them They come pre-packaged with current limiting resistors and nice plastic carriers. This made it easy to create arrays of a large number of super-bright LEDs, without all the hassle and labor of creating our own custom configuration.

Each stick uses about 30mA @ 12V. This is actually pretty good considering how bright they are. 30mA is a fraction of what an equivalent neon tube would pull. It started out as just hours and minutes. Then it was obvious we needed a colon. Then the seconds were so cool that we just had to have them, so in the end, it was two colons and 6 digits. In all: 2. 76Amps! At 12V is ~33Watt power supply. This is not small by any means. Come to mention it - perhaps we could use an ATX power supply. Hmm. Maybe later. At this time, we are using a basic variable bench power supply from Mastech, the HY1803D. With an 18V 3A max output, it handles the 12V @ 3A requirement easily. Originally I was going to simply screw the light bars onto the wall in a 7-segment digit configuration.

That`s where things turned south. The LED bars are fabulous! But the LED intensity is so high, it`s painful to look at. So we needed to diffuse the LED light a bit and create a better shape to the light. Shopping at the local Home Depot produced a large selection of potential options. Using a Styrene sheet of plastic (commonly used with 24x48" fluorescent panel ceilings) l was able to get rid of the `spots` of LED light. The problem was that the styrene had to be ~2" away from the LED to get rid of the spots. I am not an optics engineer. So I decided on using 1 1/2" sheet of Styrofoam to create a light box of sorts around each set of light bars.

Oddly enough, the sheets of Styrofoam came in 24x48" sheets as well. So did the 1/8" fiber board (lighter, cheaper, and easier to cut then real wood). So it was decided! The digits would be 24" tall. I could replicate this! So I increased the print size to 24". Using MS Publisher to create a multi-sheet printout of standard 8. 5x11" sheets of paper, I taped the pages together and cut out the segments - I had my stencil! Couple thoughts mid-conversation here - I decided to split the clock into multiple digits. This simplifies manufacturing because you just have to make the same framed digit, as many times as you need. By separating the digits, you get rid of any ugly seams in the middle of your clock (imagine the cost and hassle a of a 12` single sheet of plastic).

This also simplified the wiring - 7 segments means 7 signal wires and 1 return wire (either power or ground) is needed. 8 wires - wait! Cat5 cables have 8 wires (4 twisted pairs). Suddenly, it was painfully simple and obvious that we should split things up and use pre-terminated, cheap, easy to find, Cat5 cable to connect all these digits to the controller.

Neat! Nuther note : I used the paper stencil many times on different layers. This was a bad idea. The paper flexes and moves around causing different layer material (fiber board, Styrofoam, or foam board) not to line up. These mis-alignments are very apparent when light starts being shown through the segments. I learned only half way through to create a master foam-board stencil. This rigid stencil moves less and creates much better alignments. So once you hav 🔗 External reference

The 12-foot tall clock project showcases an innovative approach to large-scale LED display design. The integration of GPS technology for automatic time-setting enhances the functionality of the clock, making it not only visually striking but also precise. The use of pre-packaged LED light bars significantly reduces the complexity and labor involved in creating a large LED display, as they are designed for easy assembly and operation. The choice of 12V operation is standard in many LED applications, providing a balance between brightness and energy efficiency.

The decision to diffuse the intense LED light is critical to creating a visually appealing display. The Styrene and Styrofoam light boxes effectively minimize hot spots and provide a uniform light distribution across the digits, enhancing readability from a distance. This is particularly important for a clock of this size, where visibility is paramount.

The construction method, which involves creating separate digits, not only simplifies the manufacturing process but also allows for modularity in design. Each digit can be produced independently, enabling easier repairs or replacements if necessary. The use of Cat5 cables for wiring is a practical solution, leveraging existing technology to facilitate connections while maintaining a tidy and organized appearance.

Overall, this project exemplifies the intersection of creativity and engineering, resulting in a large-scale, functional art piece that effectively utilizes modern LED technology and design principles. The thoughtful consideration of materials, methods, and technologies involved in the clock’s construction contributes to its success as both a timekeeping device and a striking visual installation.We discussed creating a 6` tall alarm clock - authentic down to the Timex face plate. While this may sound like a silly idea to begin with, it quickly became obvious just how difficult it would be to build at that scale so the project was scuttled. Recently, I came across a source for pre-package LED light bars that rejuvenated my need for a big clock. Why not So here is the little project that grew to 12 feet. We added a GPS receiver so now we have a 12` clock that sets itself, displays hours/minutes/seconds, and is accurate to 100ns. Beat that bed side alarm! These light bars, as I like to call them, use three LEDs and run on 12V. Why use them They come pre-packaged with current limiting resistors and nice plastic carriers. This made it easy to create arrays of a large number of super-bright LEDs, without all the hassle and labor of creating our own custom configuration.

Each stick uses about 30mA @ 12V. This is actually pretty good considering how bright they are. 30mA is a fraction of what an equivalent neon tube would pull. It started out as just hours and minutes. Then it was obvious we needed a colon. Then the seconds were so cool that we just had to have them, so in the end, it was two colons and 6 digits. In all: 2. 76Amps! At 12V is ~33Watt power supply. This is not small by any means. Come to mention it - perhaps we could use an ATX power supply. Hmm. Maybe later. At this time, we are using a basic variable bench power supply from Mastech, the HY1803D. With an 18V 3A max output, it handles the 12V @ 3A requirement easily. Originally I was going to simply screw the light bars onto the wall in a 7-segment digit configuration.

That`s where things turned south. The LED bars are fabulous! But the LED intensity is so high, it`s painful to look at. So we needed to diffuse the LED light a bit and create a better shape to the light. Shopping at the local Home Depot produced a large selection of potential options. Using a Styrene sheet of plastic (commonly used with 24x48" fluorescent panel ceilings) l was able to get rid of the `spots` of LED light. The problem was that the styrene had to be ~2" away from the LED to get rid of the spots. I am not an optics engineer. So I decided on using 1 1/2" sheet of Styrofoam to create a light box of sorts around each set of light bars.

Oddly enough, the sheets of Styrofoam came in 24x48" sheets as well. So did the 1/8" fiber board (lighter, cheaper, and easier to cut then real wood). So it was decided! The digits would be 24" tall. I could replicate this! So I increased the print size to 24". Using MS Publisher to create a multi-sheet printout of standard 8. 5x11" sheets of paper, I taped the pages together and cut out the segments - I had my stencil! Couple thoughts mid-conversation here - I decided to split the clock into multiple digits. This simplifies manufacturing because you just have to make the same framed digit, as many times as you need. By separating the digits, you get rid of any ugly seams in the middle of your clock (imagine the cost and hassle a of a 12` single sheet of plastic).

This also simplified the wiring - 7 segments means 7 signal wires and 1 return wire (either power or ground) is needed. 8 wires - wait! Cat5 cables have 8 wires (4 twisted pairs). Suddenly, it was painfully simple and obvious that we should split things up and use pre-terminated, cheap, easy to find, Cat5 cable to connect all these digits to the controller.

Neat! Nuther note : I used the paper stencil many times on different layers. This was a bad idea. The paper flexes and moves around causing different layer material (fiber board, Styrofoam, or foam board) not to line up. These mis-alignments are very apparent when light starts being shown through the segments. I learned only half way through to create a master foam-board stencil. This rigid stencil moves less and creates much better alignments. So once you hav 🔗 External reference