15 kV @ 30 mA Floating-Output AC or DC High-Voltage Power Supply

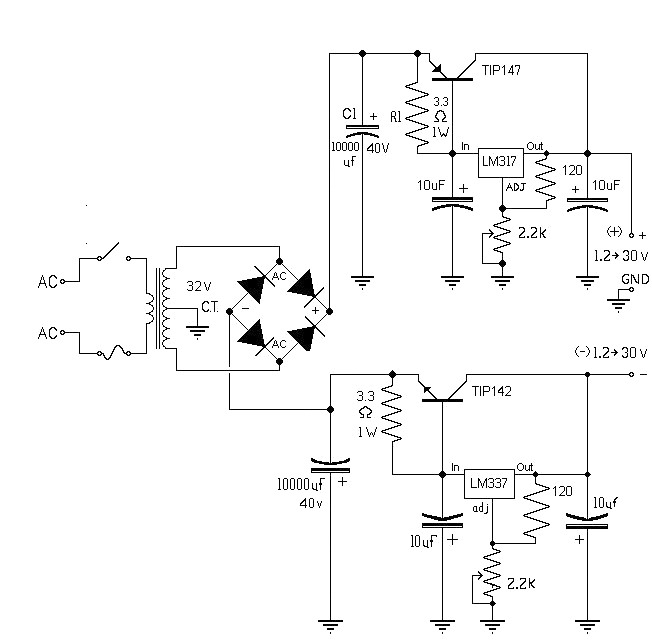

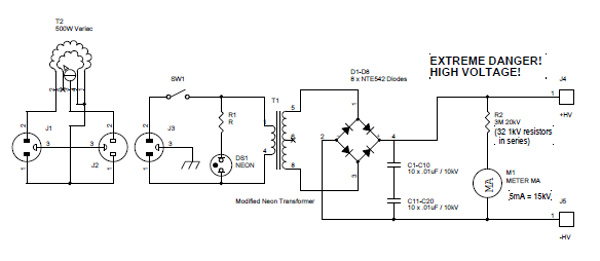

Transformers designed for powering large neon signs are cost-effective and highly reliable. Typically, the secondary winding is center-tapped, which restricts the full utilization of its peak-to-peak output in scenarios where one terminal must be grounded. In the power supply detailed here, the high-voltage transformer was removed from its metal enclosure to isolate the center tap from ground. This necessitates careful application of a thick insulating layer on the transformer. A complete can of Shellac was used to meticulously coat and re-coat the transformer. A robust Delrin insulating bracket was constructed for the modified transformer, which was then placed inside a grounded metallic enclosure. High-voltage cable was utilized for wiring, further insulated with thick silicone tubing. High-voltage putty (GC ELECTRONICS # 10-8882) was generously applied for additional insulation. The high-voltage connectors were sourced from Surplus Sales of Nebraska. To achieve a variable AC output, a 500 W variac was employed. It is important to note that neon-tube transformers are typically designed to first generate a voltage spike to initiate gas discharge, subsequently entering a constant-current mode. Therefore, the output voltage can fluctuate significantly based on the load. A one-to-one voltage relationship between the variac's output (the input to the neon transformer) and the neon transformer’s output is only feasible under very light loads. A floating DC output is produced through full-wave rectification and filtering of the neon transformer’s output. Eight NTE542 high voltage diodes, commonly used in small microwave ovens, were used to construct a full-wave bridge rectifier as illustrated in the schematic diagram. Twenty 0.01 µF capacitors rated at 10 kV are employed to filter the rectified voltage. A surplus panel meter, marked in kV and likely sourced from an X-ray machine, was used along with a series of resistors to measure the output voltage. This power supply was originally designed to operate a Chinese DC-powered CO2 laser tube but has since become a valuable addition to a collection of high-voltage power supplies for operating a plasma generator.

The described power supply circuit utilizes a high-voltage transformer specifically designed for neon signs, which is modified to enhance safety and functionality. The transformer is center-tapped, allowing for a grounded reference point, but in this configuration, it has been isolated to maximize the output voltage available for various applications. The use of Shellac as an insulating material is crucial for ensuring that the transformer remains safe to operate at high voltages, preventing any accidental discharge.

The Delrin bracket serves as a sturdy mechanical support while providing additional electrical insulation. The incorporation of high-voltage cables and silicone tubing further enhances the safety of the system, ensuring that all connections are properly insulated against potential arcing or short circuits. The application of high-voltage putty adds another layer of protection, particularly at critical junctions where high-voltage components are connected.

The variac allows for precise control of the input voltage to the neon transformer, enabling the user to adjust the output voltage as needed. However, caution is advised since the output voltage can vary significantly depending on the load conditions. The full-wave bridge rectifier composed of NTE542 diodes is designed to convert the AC output from the transformer into a usable DC voltage. The filtering capacitors smooth out the rectified voltage, ensuring a stable DC output suitable for powering sensitive electronic devices.

The inclusion of a panel meter provides real-time feedback on the output voltage, allowing for safe operation and monitoring of the system. Overall, this power supply design exemplifies a practical approach to high-voltage applications, combining safety, reliability, and versatility in its construction and intended use.Transformers made for powering large neon signs are inexpensive and very reliable. Most commonly, the secondary is center-tapped, which prevents the use of its full peak-to-peak output in applications where one of the terminals needs to be grounded. In the power supply described in this post, I took out the high-voltage transformer out of its metal lic enclosure to isolate the center tap from ground. This requires very careful application of a thick insulated layer to the transformer. I used a full can of Shellac to patiently coat and re-coat the transformer. I built a thick Delrin insulating bracket for the modifiedtransformer, and placed it inside a grounded metallic enclosure. I wired it using high-voltage cable that is further insulated by thick silicone tubing. Iliberally use high-voltage putty (GC ELECTRONICS # 10-8882) for insulation. I purchased the high-voltage connectors at Surplus Sales of Nebraska. To obtain a variable AC output, I use a 500 W variac. It must be remembered that neon-tube transformers are commonly designed to first produce a voltage spike to start discharge in the gas, and then enter constant-current mode.

As such, the voltage will vary quite a bit depending on the load. A one-to-one voltagerelationship between the variac`s output (the input to the neon transformer) and the neon transformer`s output is only possible for very light loads. Floating DC output is generated by full-wave rectification and filtering of the neon transformer`s output.

I used eight NTE542 high voltage diodes (commonly used in small microwave ovens) to build a full-wave-bridge rectifier as shown in the schematic diagram above. Twenty 0. 01 uF @ 10 kV capacitors are used to filter the rectified voltage. I used asurplus panel meter (labeled in kV, probably from an X-ray machine) with a string of resistors to measure the output voltage.

I originally built this power supply to run a Chinese DC-powered CO2 laser tube, but it has proven to be a great addition to my collection of high-voltage power supplies for running my plasma generator. 🔗 External reference

The described power supply circuit utilizes a high-voltage transformer specifically designed for neon signs, which is modified to enhance safety and functionality. The transformer is center-tapped, allowing for a grounded reference point, but in this configuration, it has been isolated to maximize the output voltage available for various applications. The use of Shellac as an insulating material is crucial for ensuring that the transformer remains safe to operate at high voltages, preventing any accidental discharge.

The Delrin bracket serves as a sturdy mechanical support while providing additional electrical insulation. The incorporation of high-voltage cables and silicone tubing further enhances the safety of the system, ensuring that all connections are properly insulated against potential arcing or short circuits. The application of high-voltage putty adds another layer of protection, particularly at critical junctions where high-voltage components are connected.

The variac allows for precise control of the input voltage to the neon transformer, enabling the user to adjust the output voltage as needed. However, caution is advised since the output voltage can vary significantly depending on the load conditions. The full-wave bridge rectifier composed of NTE542 diodes is designed to convert the AC output from the transformer into a usable DC voltage. The filtering capacitors smooth out the rectified voltage, ensuring a stable DC output suitable for powering sensitive electronic devices.

The inclusion of a panel meter provides real-time feedback on the output voltage, allowing for safe operation and monitoring of the system. Overall, this power supply design exemplifies a practical approach to high-voltage applications, combining safety, reliability, and versatility in its construction and intended use.Transformers made for powering large neon signs are inexpensive and very reliable. Most commonly, the secondary is center-tapped, which prevents the use of its full peak-to-peak output in applications where one of the terminals needs to be grounded. In the power supply described in this post, I took out the high-voltage transformer out of its metal lic enclosure to isolate the center tap from ground. This requires very careful application of a thick insulated layer to the transformer. I used a full can of Shellac to patiently coat and re-coat the transformer. I built a thick Delrin insulating bracket for the modifiedtransformer, and placed it inside a grounded metallic enclosure. I wired it using high-voltage cable that is further insulated by thick silicone tubing. Iliberally use high-voltage putty (GC ELECTRONICS # 10-8882) for insulation. I purchased the high-voltage connectors at Surplus Sales of Nebraska. To obtain a variable AC output, I use a 500 W variac. It must be remembered that neon-tube transformers are commonly designed to first produce a voltage spike to start discharge in the gas, and then enter constant-current mode.

As such, the voltage will vary quite a bit depending on the load. A one-to-one voltagerelationship between the variac`s output (the input to the neon transformer) and the neon transformer`s output is only possible for very light loads. Floating DC output is generated by full-wave rectification and filtering of the neon transformer`s output.

I used eight NTE542 high voltage diodes (commonly used in small microwave ovens) to build a full-wave-bridge rectifier as shown in the schematic diagram above. Twenty 0. 01 uF @ 10 kV capacitors are used to filter the rectified voltage. I used asurplus panel meter (labeled in kV, probably from an X-ray machine) with a string of resistors to measure the output voltage.

I originally built this power supply to run a Chinese DC-powered CO2 laser tube, but it has proven to be a great addition to my collection of high-voltage power supplies for running my plasma generator. 🔗 External reference