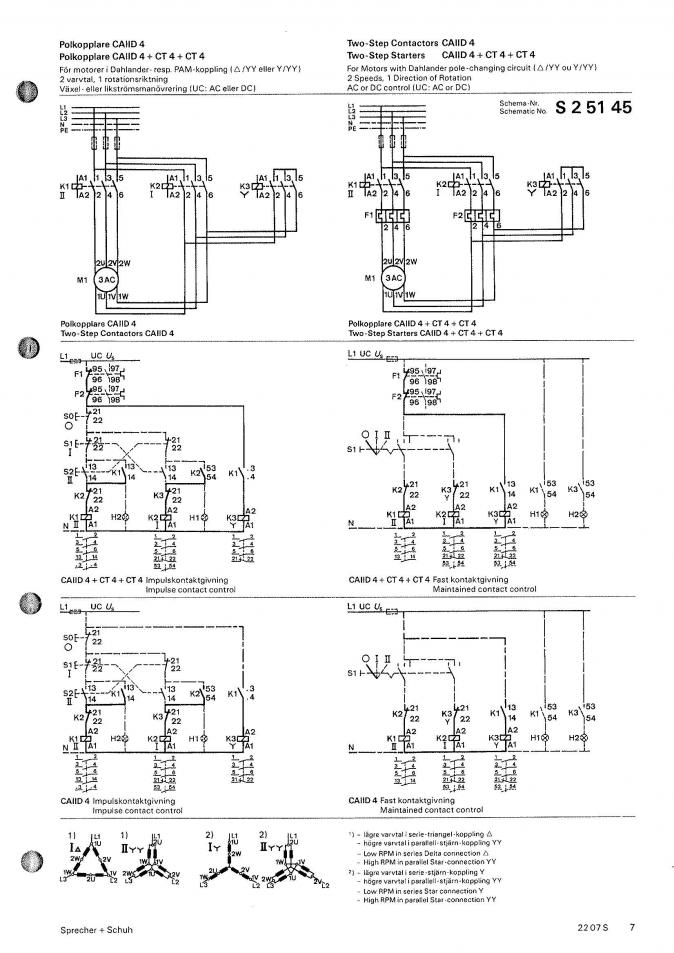

220/440V nameplate on 2-speed motor

A NOS lathe is available, but it lacks any historical information. It appears to be purpose-built, and it is important to note that there is no available technical support for this equipment.

The absence of historical context for the NOS lathe presents unique challenges and considerations for potential users. When dealing with a purpose-built lathe, it is essential to understand its design specifications, operational capabilities, and any unique features that differentiate it from standard lathes.

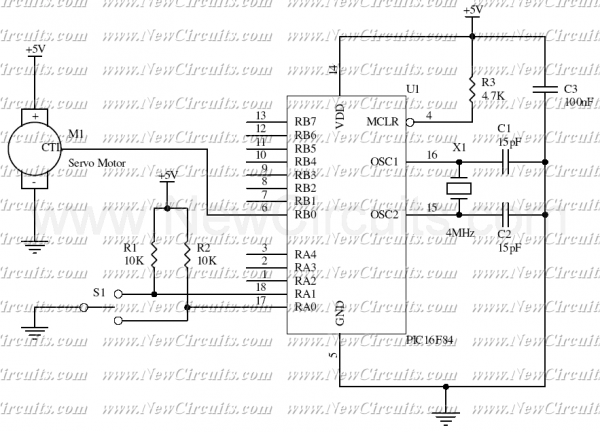

To effectively utilize the lathe, a thorough examination of its components is necessary. Key areas of focus should include the motor specifications, drive system, and control mechanisms. The motor's power rating and torque characteristics will determine the lathe's capacity for various machining tasks. Additionally, understanding the drive system, whether it is belt-driven or direct drive, will provide insights into the lathe's operational efficiency and maintenance requirements.

The control system should also be assessed to determine its ease of use and adaptability. If the lathe incorporates any programmable features or CNC capabilities, familiarity with the software and programming language will be crucial for maximizing its functionality.

In the absence of technical support, it may be beneficial to consult with industry professionals or reference manuals from similar lathes to gain insights into troubleshooting and maintenance practices. Furthermore, documenting any modifications or repairs made to the lathe can provide valuable information for future users or technicians.

Overall, while the lack of history and technical support may pose challenges, a methodical approach to understanding the lathe's design and operational characteristics can lead to successful utilization in various machining applications.I have a NOS lathe with NO history. Period. I think it was maybe purpose-built. In any case, I mention it because there is really no "tech-support.. 🔗 External reference

The absence of historical context for the NOS lathe presents unique challenges and considerations for potential users. When dealing with a purpose-built lathe, it is essential to understand its design specifications, operational capabilities, and any unique features that differentiate it from standard lathes.

To effectively utilize the lathe, a thorough examination of its components is necessary. Key areas of focus should include the motor specifications, drive system, and control mechanisms. The motor's power rating and torque characteristics will determine the lathe's capacity for various machining tasks. Additionally, understanding the drive system, whether it is belt-driven or direct drive, will provide insights into the lathe's operational efficiency and maintenance requirements.

The control system should also be assessed to determine its ease of use and adaptability. If the lathe incorporates any programmable features or CNC capabilities, familiarity with the software and programming language will be crucial for maximizing its functionality.

In the absence of technical support, it may be beneficial to consult with industry professionals or reference manuals from similar lathes to gain insights into troubleshooting and maintenance practices. Furthermore, documenting any modifications or repairs made to the lathe can provide valuable information for future users or technicians.

Overall, while the lack of history and technical support may pose challenges, a methodical approach to understanding the lathe's design and operational characteristics can lead to successful utilization in various machining applications.I have a NOS lathe with NO history. Period. I think it was maybe purpose-built. In any case, I mention it because there is really no "tech-support.. 🔗 External reference