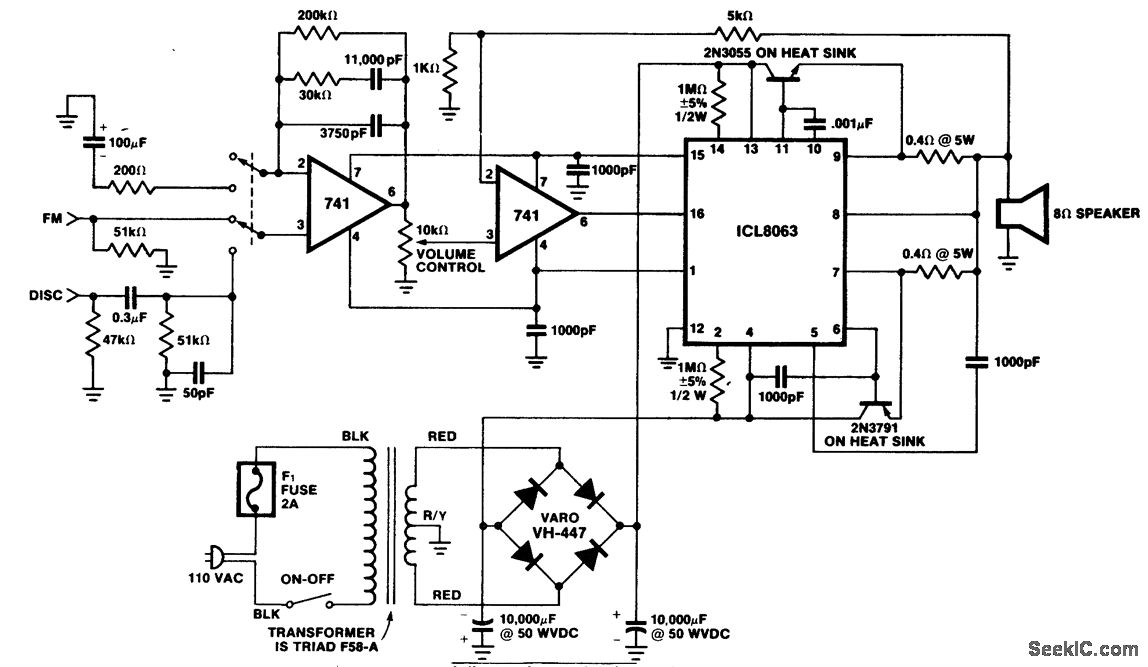

50 Watt Power Amplifier

The supply voltage should be about +/- 35 Volts at full load, which will let this little guy provide a maximum of 56 Watts (rated minimum output at 25 degrees C). To enable maximum power, it is important to get the lowest possible case to heatsink thermal resistance. This will be achieved by mounting with no insulating mica washer, but be warned that the heatsink will be at the -ve supply voltage and will have to be insulated from the chassis. More: Voltage gain is 27dB as shown, but this can be changed by using a different value resistor for the feedback path (R3, currently 22k, between pins 3 and 9). The inductor consists of 10 turns of 0.4mm enamelled copper wire, wound around the body of the 10 O.

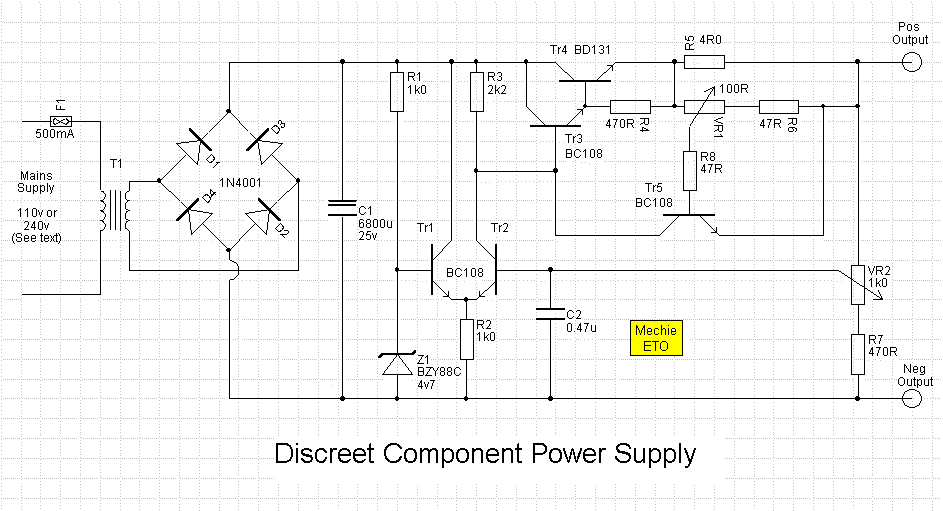

The described circuit operates with a dual power supply of approximately +/- 35 Volts, allowing for a maximum output power of 56 Watts under full load conditions. This configuration is particularly suited for audio amplification or similar applications where high power and low distortion are critical. The operational amplifier or transistor stage within the circuit must be designed to handle the thermal load effectively. The thermal management aspect is crucial; thus, the heatsink must be mounted directly to the component without an insulating mica washer to minimize thermal resistance. However, it is essential to ensure that the heatsink is properly insulated from the chassis, as it will be at a negative supply voltage, preventing any accidental short circuits or damage to the circuit.

The voltage gain of the amplifier is set at 27dB, which can be adjusted by changing the feedback resistor (R3) currently specified as 22k ohms connected between pins 3 and 9 of the amplification stage. This feedback configuration allows for flexibility in gain adjustment, enabling the designer to tailor the circuit's performance to specific requirements. The inductor used in the circuit is constructed with 10 turns of 0.4mm enamelled copper wire, wound around a core with a resistance of 10 ohms. The choice of wire gauge and the number of turns are critical for achieving the desired inductance and ensuring efficient operation in the intended frequency range.

In summary, attention to thermal management, adjustable gain through feedback resistor selection, and careful inductor design are critical components of this circuit's performance and reliability. Proper implementation of these elements will ensure optimal functionality and longevity of the electronic device.The supply voltage should be about +/- 35 Volts at full load, which will let this little guy provide a maximum of 56 Watts (rated minimum output at 25 degrees C). To enable maximum power, it is important to get the lowest possible case to heatsink thermal resistance.

This will be achieved by mounting with no insulating mica washer, but be warned that the heatsink will be at the -ve supply voltage and will have to be insulated from the chassis. Voltage gain is 27dB as shown, but this can be changed by using a different value resistor for the feedback path (R3, currently 22k, between pins 3 and 9). The inductor consists of 10 turns of 0.4mm enamelled copper wire, wound around the body of the 10 O 🔗 External reference

The described circuit operates with a dual power supply of approximately +/- 35 Volts, allowing for a maximum output power of 56 Watts under full load conditions. This configuration is particularly suited for audio amplification or similar applications where high power and low distortion are critical. The operational amplifier or transistor stage within the circuit must be designed to handle the thermal load effectively. The thermal management aspect is crucial; thus, the heatsink must be mounted directly to the component without an insulating mica washer to minimize thermal resistance. However, it is essential to ensure that the heatsink is properly insulated from the chassis, as it will be at a negative supply voltage, preventing any accidental short circuits or damage to the circuit.

The voltage gain of the amplifier is set at 27dB, which can be adjusted by changing the feedback resistor (R3) currently specified as 22k ohms connected between pins 3 and 9 of the amplification stage. This feedback configuration allows for flexibility in gain adjustment, enabling the designer to tailor the circuit's performance to specific requirements. The inductor used in the circuit is constructed with 10 turns of 0.4mm enamelled copper wire, wound around a core with a resistance of 10 ohms. The choice of wire gauge and the number of turns are critical for achieving the desired inductance and ensuring efficient operation in the intended frequency range.

In summary, attention to thermal management, adjustable gain through feedback resistor selection, and careful inductor design are critical components of this circuit's performance and reliability. Proper implementation of these elements will ensure optimal functionality and longevity of the electronic device.The supply voltage should be about +/- 35 Volts at full load, which will let this little guy provide a maximum of 56 Watts (rated minimum output at 25 degrees C). To enable maximum power, it is important to get the lowest possible case to heatsink thermal resistance.

This will be achieved by mounting with no insulating mica washer, but be warned that the heatsink will be at the -ve supply voltage and will have to be insulated from the chassis. Voltage gain is 27dB as shown, but this can be changed by using a different value resistor for the feedback path (R3, currently 22k, between pins 3 and 9). The inductor consists of 10 turns of 0.4mm enamelled copper wire, wound around the body of the 10 O 🔗 External reference