A CMOS the spot welding time adjustment circuit b

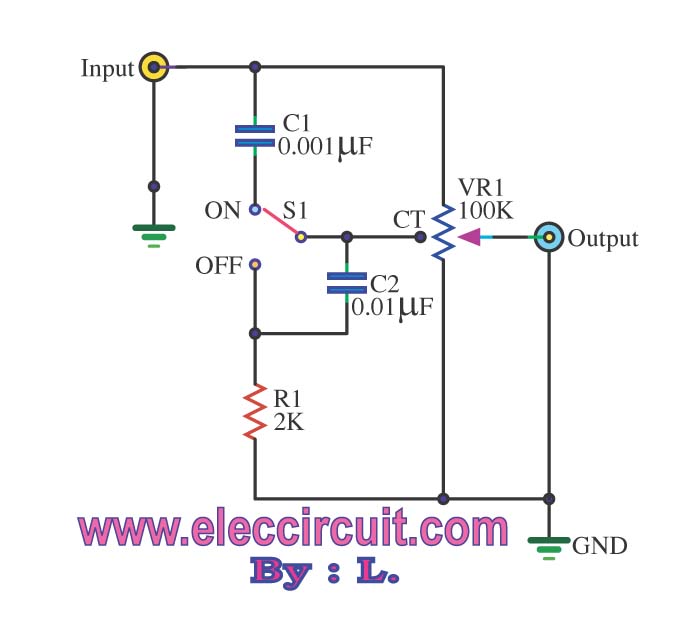

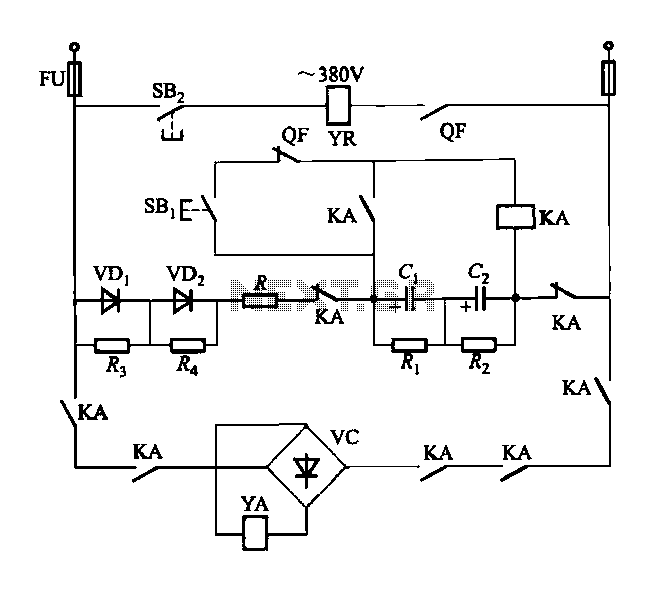

A CMOS-based circuit designed for adjusting the time of spot welding. This circuit utilizes a CMOS device that allows for cycle selection ranging from 1 to 99 cycles. In practical applications, most users find that adjustments within 10 cycles are sufficient. The schematic integrates various CMOS components, including gates 1 to 20 (C036), counters 21 and 22 (C180), D flip-flops 25 and 26 (C043), and a seven-segment decoder (C036) for LED digital displays (BS202).

The described circuit employs complementary metal-oxide-semiconductor (CMOS) technology to facilitate precise control over the timing of spot welding operations. The cycle adjustment feature is crucial for optimizing the welding process, allowing users to select the appropriate duration for different materials and thicknesses. The range of 1 to 99 cycles provides flexibility, although typical usage often requires fewer cycles, with a common setting around 10.

The integration of gates (C036) serves as the logic control elements, enabling the configuration of the desired cycle count. The counters (C180) play a vital role in tracking the number of cycles completed during the welding process, ensuring accurate timing and repeatability. The D flip-flops (C043) are utilized to store the state of the control signals, providing a stable output that can be used to trigger the welding operation.

Additionally, the inclusion of a seven-segment decoder (C036) enhances user interaction by displaying the selected cycle count on an LED display (BS202). This feature allows operators to easily monitor and adjust settings in real-time, contributing to improved operational efficiency and safety.

Overall, the CMOS-based spot welding time adjustment circuit is a sophisticated solution that combines various electronic components to deliver precise control and user-friendly operation, making it suitable for a range of industrial applications.A CMOS constituting the spot welding time adjustment circuit b The number of cycles it uses CMOS device composed of a control circuit, optionally in the range of 1 to 99 cycles to choose from. In actual use, most of them within 10 cycles adjusted enough. Drawing, are integrated with CMOS circuitry; gates 1 to 20 available C036; C180 counter available 21,22; D flip-flops 25, 26 Available C043; seven segment decoder applications C036; LED digital works BS202.

The described circuit employs complementary metal-oxide-semiconductor (CMOS) technology to facilitate precise control over the timing of spot welding operations. The cycle adjustment feature is crucial for optimizing the welding process, allowing users to select the appropriate duration for different materials and thicknesses. The range of 1 to 99 cycles provides flexibility, although typical usage often requires fewer cycles, with a common setting around 10.

The integration of gates (C036) serves as the logic control elements, enabling the configuration of the desired cycle count. The counters (C180) play a vital role in tracking the number of cycles completed during the welding process, ensuring accurate timing and repeatability. The D flip-flops (C043) are utilized to store the state of the control signals, providing a stable output that can be used to trigger the welding operation.

Additionally, the inclusion of a seven-segment decoder (C036) enhances user interaction by displaying the selected cycle count on an LED display (BS202). This feature allows operators to easily monitor and adjust settings in real-time, contributing to improved operational efficiency and safety.

Overall, the CMOS-based spot welding time adjustment circuit is a sophisticated solution that combines various electronic components to deliver precise control and user-friendly operation, making it suitable for a range of industrial applications.A CMOS constituting the spot welding time adjustment circuit b The number of cycles it uses CMOS device composed of a control circuit, optionally in the range of 1 to 99 cycles to choose from. In actual use, most of them within 10 cycles adjusted enough. Drawing, are integrated with CMOS circuitry; gates 1 to 20 available C036; C180 counter available 21,22; D flip-flops 25, 26 Available C043; seven segment decoder applications C036; LED digital works BS202.