A control two water supply frequency control circuit a

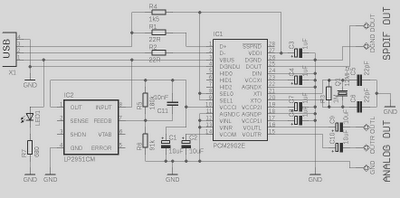

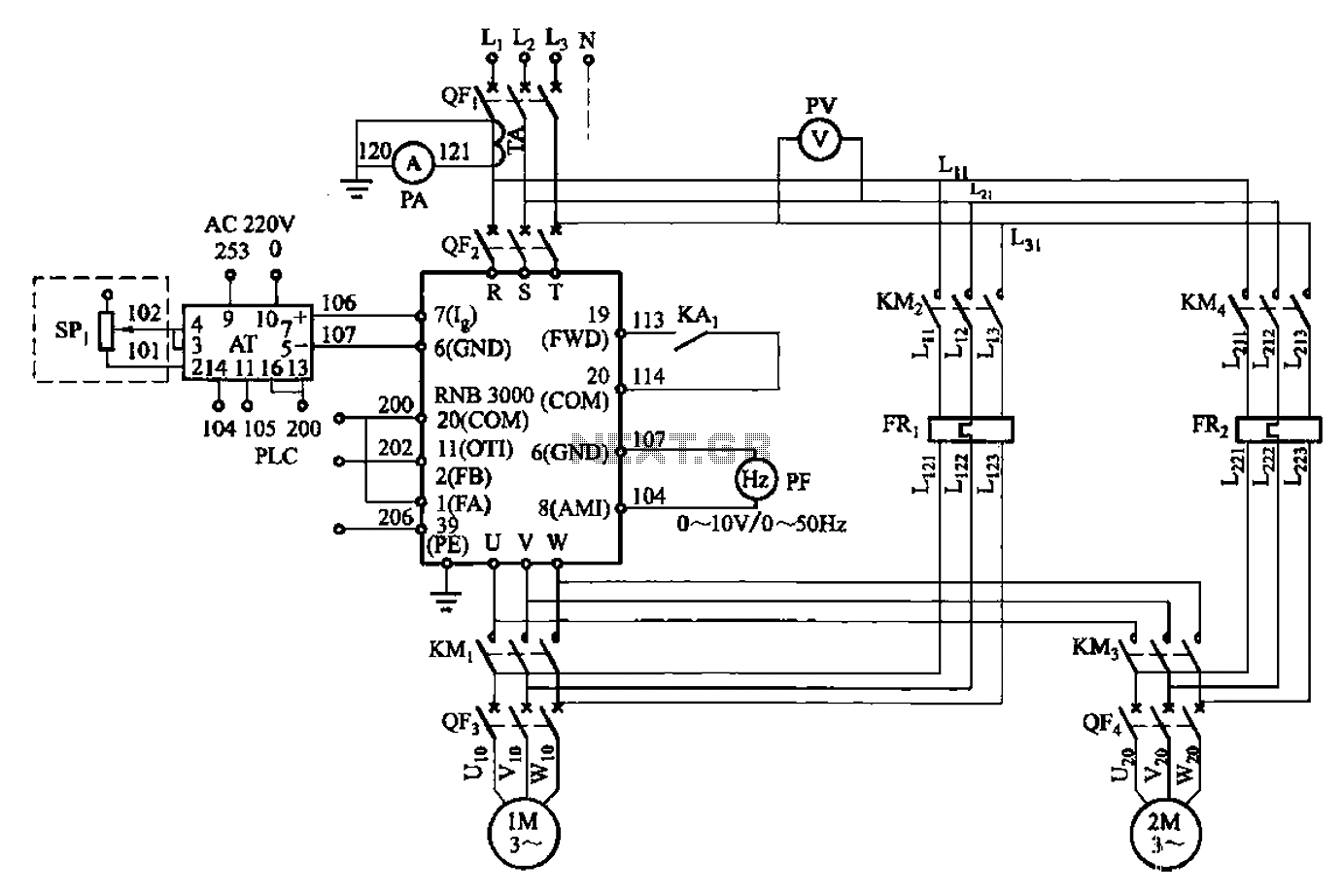

A control circuit for two motors, specifically for frequency control in a constant pressure water supply system, is illustrated in Figure 5-23. The circuit includes fault output terminals labeled 1 and 2, analog feedback current input terminals labeled 6 and 7, analog output terminals for the sub labeled 6 and 8, forward run terminals labeled 19 and 20, and programmable digital output terminals labeled 11 and 20.

The described circuit operates as a frequency control mechanism for two motors that regulate the pressure of water in a supply system. The primary function of this circuit is to maintain a constant pressure by adjusting the motor speeds based on feedback received from various sensors.

The fault output terminals (1 and 2) are crucial for monitoring the operational status of the motors. If an anomaly is detected, these terminals will relay fault signals to a monitoring system, allowing for timely maintenance or intervention.

The analog feedback current input terminals (6 and 7) receive signals from current sensors that monitor the actual motor performance. This feedback is essential for the control system to make real-time adjustments to the motor speeds, ensuring that the desired pressure levels are consistently achieved.

Analog output terminals (6 and 8) are used to provide data to other components of the system, such as a controller or display unit. This data can include information on current motor speeds or pressure levels, allowing operators to have a clear view of the system's performance.

The forward run terminals (19 and 20) are responsible for initiating the operation of the motors in a forward direction. These terminals are typically connected to a control switch or relay that activates the motors when water supply is required.

Programmable digital output terminals (11 and 20) allow for customization of the control circuit’s functions. These outputs can be programmed to perform specific tasks, such as activating alarms or controlling additional components based on the operational status of the motors.

Overall, this control circuit is integral to maintaining efficient operation in a constant pressure water supply system, ensuring that the motors function optimally while providing critical feedback and control capabilities.A control two (namely a frequency control two motors) Frequency constant pressure water supply control circuit shown in Figure 5-23. Figure, 1,2 fault output terminal; 6,7 anal og feedback current input terminals; 6,8 is the analog output of the sub; 19, 20 to run forward terminal; 11, 20 programmable digital output terminal.

The described circuit operates as a frequency control mechanism for two motors that regulate the pressure of water in a supply system. The primary function of this circuit is to maintain a constant pressure by adjusting the motor speeds based on feedback received from various sensors.

The fault output terminals (1 and 2) are crucial for monitoring the operational status of the motors. If an anomaly is detected, these terminals will relay fault signals to a monitoring system, allowing for timely maintenance or intervention.

The analog feedback current input terminals (6 and 7) receive signals from current sensors that monitor the actual motor performance. This feedback is essential for the control system to make real-time adjustments to the motor speeds, ensuring that the desired pressure levels are consistently achieved.

Analog output terminals (6 and 8) are used to provide data to other components of the system, such as a controller or display unit. This data can include information on current motor speeds or pressure levels, allowing operators to have a clear view of the system's performance.

The forward run terminals (19 and 20) are responsible for initiating the operation of the motors in a forward direction. These terminals are typically connected to a control switch or relay that activates the motors when water supply is required.

Programmable digital output terminals (11 and 20) allow for customization of the control circuit’s functions. These outputs can be programmed to perform specific tasks, such as activating alarms or controlling additional components based on the operational status of the motors.

Overall, this control circuit is integral to maintaining efficient operation in a constant pressure water supply system, ensuring that the motors function optimally while providing critical feedback and control capabilities.A control two (namely a frequency control two motors) Frequency constant pressure water supply control circuit shown in Figure 5-23. Figure, 1,2 fault output terminal; 6,7 anal og feedback current input terminals; 6,8 is the analog output of the sub; 19, 20 to run forward terminal; 11, 20 programmable digital output terminal.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713