AC Current Monitor

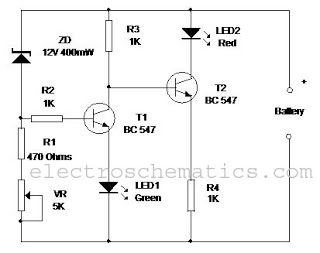

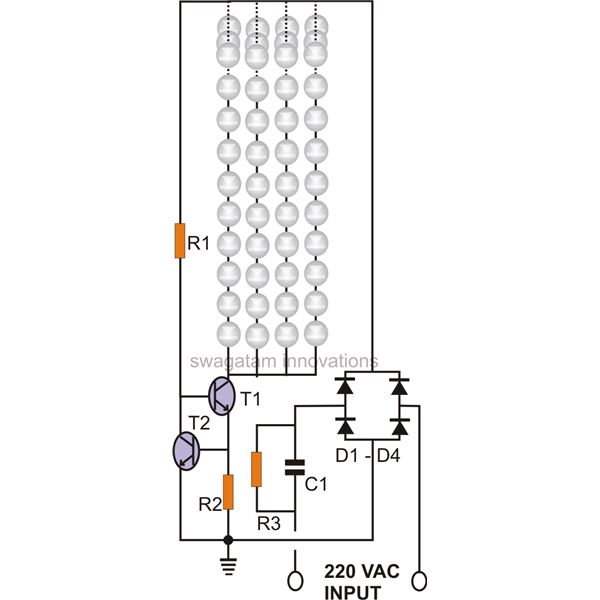

This circuit was designed on request to remotely monitor when a couple of electric heaters have been left on. Its sensor must be placed in contact with the feeder to be able to monitor when the power cable is drawing current, thus causing the circuit to switch on a LED.

The circuit utilizes a current sensing mechanism, which is critical for detecting the operational state of the electric heaters. A common approach for this is to use a current transformer or a Hall effect sensor that can be clamped around the power cable. This sensor is capable of generating a voltage signal proportional to the current flowing through the feeder.

The output from the current sensor is fed into a comparator circuit, which compares the sensor output against a predefined threshold voltage. When the current exceeds this threshold, indicating that the heaters are operational, the comparator output switches high. This transition activates a microcontroller or a transistor that drives an LED indicator.

The LED serves as a visual alert, indicating that the heaters are on. Additionally, the circuit may include a wireless transmission module, allowing real-time monitoring and notifications to be sent to a remote device, such as a smartphone or computer. This feature enhances the utility of the circuit, providing users with the ability to monitor the status of their heating devices from a distance.

Power supply considerations for this circuit must also be accounted for. A low-power design is recommended to ensure that the circuit can operate continuously without excessive energy consumption. The circuit can be powered using a small battery or a low-voltage AC power supply, depending on the installation environment.

In summary, this remote monitoring circuit for electric heaters integrates current sensing, signal processing, and visual indication to provide an effective solution for ensuring safety and energy efficiency in heating applications.This circuit was designed on request, to remotely monitor when a couple of electric heaters have been left on. Its sensor must be placed in contact with the feeder to be able to monitor when the power cable is drawing current, thus causing the circuit to switch-on a LED.

🔗 External reference

The circuit utilizes a current sensing mechanism, which is critical for detecting the operational state of the electric heaters. A common approach for this is to use a current transformer or a Hall effect sensor that can be clamped around the power cable. This sensor is capable of generating a voltage signal proportional to the current flowing through the feeder.

The output from the current sensor is fed into a comparator circuit, which compares the sensor output against a predefined threshold voltage. When the current exceeds this threshold, indicating that the heaters are operational, the comparator output switches high. This transition activates a microcontroller or a transistor that drives an LED indicator.

The LED serves as a visual alert, indicating that the heaters are on. Additionally, the circuit may include a wireless transmission module, allowing real-time monitoring and notifications to be sent to a remote device, such as a smartphone or computer. This feature enhances the utility of the circuit, providing users with the ability to monitor the status of their heating devices from a distance.

Power supply considerations for this circuit must also be accounted for. A low-power design is recommended to ensure that the circuit can operate continuously without excessive energy consumption. The circuit can be powered using a small battery or a low-voltage AC power supply, depending on the installation environment.

In summary, this remote monitoring circuit for electric heaters integrates current sensing, signal processing, and visual indication to provide an effective solution for ensuring safety and energy efficiency in heating applications.This circuit was designed on request, to remotely monitor when a couple of electric heaters have been left on. Its sensor must be placed in contact with the feeder to be able to monitor when the power cable is drawing current, thus causing the circuit to switch-on a LED.

🔗 External reference