AIR-FILTER SENSOR FOR HOME-USED AIR CONDITIONERS

This project involves the design of an air-filter sensor intended for use in home heating and cooling systems. The project encompasses conceptual design, analysis, implementation, testing, and modifications. Initially, the study focuses on comparing air quality and power consumption between clean and dirty air filters. A photo sensor circuit featuring an ultra-bright LED emitter and a phototransistor receiver is employed to detect dust particles. When a predetermined amount of dust accumulates on the filter, a red warning LED activates, indicating that the light beam between the emitter and receiver is obstructed. The emitter and receiver are mounted on a simple fixture that can be easily attached to any air filter. Additionally, a cost analysis indicates that this design could significantly reduce electricity expenses if filters are replaced regularly. A crucial aspect of Engineering Technology (ET) education is the implementation of senior project designs, allowing students to apply knowledge acquired from other courses to address practical problems. Typically, Engineering Technology students undertake such projects in their senior year, working in small groups to tackle projects sourced from local industries, particularly small businesses lacking engineering staff for product development or manufacturing improvements. Faculty members, companies, the College's Technology Application Center, or students employed by these companies may initiate contacts for project opportunities. While student projects can vary widely, they must include specific components: design analysis, computer-generated drawings, vendor contacts, literature searches for products and manufacturing techniques, material selection, and, if feasible, prototype manufacturing and testing. The project described here was proposed to faculty members by a regional director. When a clean air filter is installed in a heating, ventilation, and air conditioning (HVAC) system, users often neglect to replace it, as it appears to have little effect on HVAC operation. However, when the air filter becomes dirty and is not replaced, air quality deteriorates, and HVAC efficiency declines. Since there is no existing literature or patents addressing this issue, a senior project team was formed to investigate and design an air-filter sensor for residential HVAC systems. Two teams are involved in the project: Team 1 conducts design analysis and fabricates components, while Team 2 performs air quality testing, cost analysis, and evaluations. The primary function of an air filter in a residential HVAC system is to block dust particles from incoming air and eliminate contaminants from recirculated air. A newly installed filter presents minimal resistance to airflow, resulting in lower friction loss and reduced energy consumption by the air mover (motor) compared to a system with a dirty filter. A clean air filter enhances air quality and provides a quicker response to temperature adjustments during HVAC operation compared to a dirty or blocked filter. To analyze airflow changes between clean and dirty filters, a simple apparatus was developed within the ET program. This apparatus consists of a rectangular box equipped with a fan and motor, featuring openings at both the fan discharge and suction ends. The suction end accommodates the installation of a standard small HVAC filter.

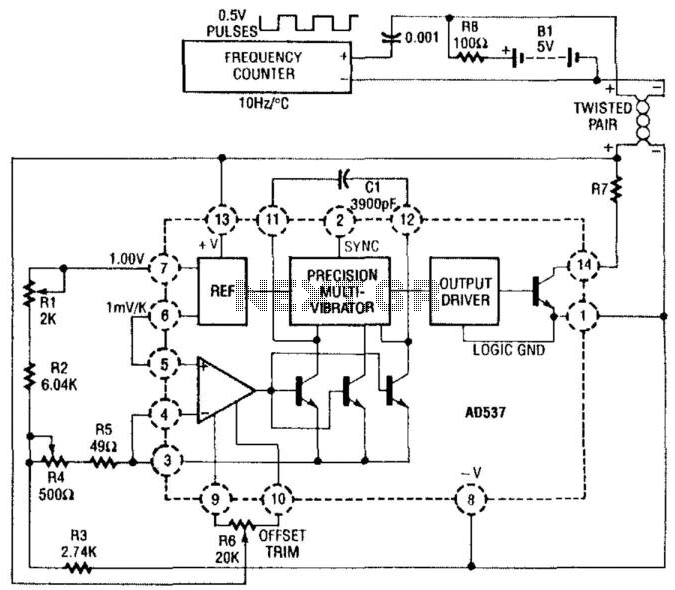

The air-filter sensor design project integrates various engineering principles and practical applications. The core of the design is the photo sensor circuit, which utilizes an ultra-bright LED as the emitter and a phototransistor as the receiver. The LED emits light, which is directed towards the phototransistor. Under normal conditions, this light beam remains uninterrupted, allowing the phototransistor to function correctly. However, as dust particles accumulate on the filter, they obstruct the light path, leading to a decrease in the amount of light detected by the phototransistor. When the light intensity falls below a certain threshold, the circuit triggers the red warning LED, providing a visual alert for filter maintenance.

The fixture designed to hold the emitter and receiver is engineered for easy installation on various types of air filters, ensuring adaptability across different HVAC systems. The materials selected for the fixture are lightweight yet durable, allowing for a straightforward mounting process without compromising the structural integrity of the air filter assembly.

In terms of energy efficiency, the project emphasizes the importance of timely filter replacements. By monitoring air quality and providing alerts for filter changes, the sensor contributes to maintaining optimal airflow and system efficiency. This, in turn, reduces energy consumption, leading to lower electricity bills for homeowners. The cost analysis conducted during the project highlights the potential savings associated with implementing this air-filter sensor, making it a valuable addition to residential HVAC systems.

Overall, this project not only addresses a practical issue in HVAC maintenance but also serves as a comprehensive educational experience for Engineering Technology students, allowing them to apply theoretical knowledge to real-world applications. The collaboration between students and local industries fosters innovation and enhances the learning experience, ultimately contributing to the development of effective engineering solutions.This is a design project of an air-filter sensor to be used in home heating and cooling system. The project includes conceptual design, analysis, implementation, tests and modifications. First, the air quality and power consumption between a clean air filter and a dirty air filter is studied. Then, a photo sensor circuit with an ultra high brightn ess LED emitter and a phototransistor receiver is used to detect dust particles. A red warning LED lights up when a specified amount of dust is collected on the filter and blocks the light beam between the emitter and the receiver. The emitter and receiver are mounted on a simple fixture and can be easily fitted on any air filter. In addition, the cost analysis shows that this design can significantly reduce the electricity bill if the filters are properly replaced.

A vital part of Engineering Technology (ET) education is the implementation of senior project designs to provide students with the opportunity to apply knowledge gained in other courses to solve practical problems. Engineering Technology students at usually take such a course in their senior year. Small groups of students (usually two) work on projects identified from one of several sources. The primary source of projects is local industry, usually small businesses. Many of these companies do not have the engineering staff to investigate new products or make major improvement in their manufacturing processes.

Contacts with these companies may be initiated by faculty members, the companies themselves, the College`s Technology Application Center (an on-campus organization that specializes in promoting economic development for the region through matching industry needs with faculty expertise, student resources and university facilities), or by students who may be working for one of the companies. While student projects may vary substantially, they must contain certain elements: design analysis, computer generated drawings, vendor contacts, literature search for products and manufacturing techniques, material selection and if possible prototype manufacture and testing.

The project described in this article was brought to the faculty members through a regional director of the When a clean air filter is installed in a heating, ventilation and air conditioning (HVAC) system, people usually forget to replace it because it does not have significant impact on the operation of a HVAC system. However, when the air filter became dirty and remained unchanged, the air quality will deteriorate, and efficiency of the HVAC system will also be reduced [1, 2, 3].

Since there is no paper or patent discussing this issue, a senior project team is formed to investigate this problem and design an air-filter sensor for a residential HVAC system. There are two teams working on the project. Team 1 performs the design analysis and fabricated the components [4]. Team 2 does air quality tests, cost analysis and testing [5]. The major purpose of installing an air filter in a residential HVAC system is to block the dusty air particles from the incoming air and remove contaminants introduced into the re-circulated air from conditioned space [1].

When a new filter is just installed, it provides little resistance to the airflow. The low resistance provides little friction loss in the system and thus requires less energy for the air mover (motor) than a system with a dirty filter. A clean air filter also produces better air quality and faster response to temperature adjustment during the same operation period of a HVAC system while compared to a dirty/blocked filter.

To better analyze the change of the airflow between a clean filter and a dirty filter, a simple apparatus was developed in the ET program [4, 5]. This apparatus is a rectangular box that has a fan and motor with openings at the fan discharge and suction ends.

The suction end has provisions for the installation of a standard small HVA 🔗 External reference

The air-filter sensor design project integrates various engineering principles and practical applications. The core of the design is the photo sensor circuit, which utilizes an ultra-bright LED as the emitter and a phototransistor as the receiver. The LED emits light, which is directed towards the phototransistor. Under normal conditions, this light beam remains uninterrupted, allowing the phototransistor to function correctly. However, as dust particles accumulate on the filter, they obstruct the light path, leading to a decrease in the amount of light detected by the phototransistor. When the light intensity falls below a certain threshold, the circuit triggers the red warning LED, providing a visual alert for filter maintenance.

The fixture designed to hold the emitter and receiver is engineered for easy installation on various types of air filters, ensuring adaptability across different HVAC systems. The materials selected for the fixture are lightweight yet durable, allowing for a straightforward mounting process without compromising the structural integrity of the air filter assembly.

In terms of energy efficiency, the project emphasizes the importance of timely filter replacements. By monitoring air quality and providing alerts for filter changes, the sensor contributes to maintaining optimal airflow and system efficiency. This, in turn, reduces energy consumption, leading to lower electricity bills for homeowners. The cost analysis conducted during the project highlights the potential savings associated with implementing this air-filter sensor, making it a valuable addition to residential HVAC systems.

Overall, this project not only addresses a practical issue in HVAC maintenance but also serves as a comprehensive educational experience for Engineering Technology students, allowing them to apply theoretical knowledge to real-world applications. The collaboration between students and local industries fosters innovation and enhances the learning experience, ultimately contributing to the development of effective engineering solutions.This is a design project of an air-filter sensor to be used in home heating and cooling system. The project includes conceptual design, analysis, implementation, tests and modifications. First, the air quality and power consumption between a clean air filter and a dirty air filter is studied. Then, a photo sensor circuit with an ultra high brightn ess LED emitter and a phototransistor receiver is used to detect dust particles. A red warning LED lights up when a specified amount of dust is collected on the filter and blocks the light beam between the emitter and the receiver. The emitter and receiver are mounted on a simple fixture and can be easily fitted on any air filter. In addition, the cost analysis shows that this design can significantly reduce the electricity bill if the filters are properly replaced.

A vital part of Engineering Technology (ET) education is the implementation of senior project designs to provide students with the opportunity to apply knowledge gained in other courses to solve practical problems. Engineering Technology students at usually take such a course in their senior year. Small groups of students (usually two) work on projects identified from one of several sources. The primary source of projects is local industry, usually small businesses. Many of these companies do not have the engineering staff to investigate new products or make major improvement in their manufacturing processes.

Contacts with these companies may be initiated by faculty members, the companies themselves, the College`s Technology Application Center (an on-campus organization that specializes in promoting economic development for the region through matching industry needs with faculty expertise, student resources and university facilities), or by students who may be working for one of the companies. While student projects may vary substantially, they must contain certain elements: design analysis, computer generated drawings, vendor contacts, literature search for products and manufacturing techniques, material selection and if possible prototype manufacture and testing.

The project described in this article was brought to the faculty members through a regional director of the When a clean air filter is installed in a heating, ventilation and air conditioning (HVAC) system, people usually forget to replace it because it does not have significant impact on the operation of a HVAC system. However, when the air filter became dirty and remained unchanged, the air quality will deteriorate, and efficiency of the HVAC system will also be reduced [1, 2, 3].

Since there is no paper or patent discussing this issue, a senior project team is formed to investigate this problem and design an air-filter sensor for a residential HVAC system. There are two teams working on the project. Team 1 performs the design analysis and fabricated the components [4]. Team 2 does air quality tests, cost analysis and testing [5]. The major purpose of installing an air filter in a residential HVAC system is to block the dusty air particles from the incoming air and remove contaminants introduced into the re-circulated air from conditioned space [1].

When a new filter is just installed, it provides little resistance to the airflow. The low resistance provides little friction loss in the system and thus requires less energy for the air mover (motor) than a system with a dirty filter. A clean air filter also produces better air quality and faster response to temperature adjustment during the same operation period of a HVAC system while compared to a dirty/blocked filter.

To better analyze the change of the airflow between a clean filter and a dirty filter, a simple apparatus was developed in the ET program [4, 5]. This apparatus is a rectangular box that has a fan and motor with openings at the fan discharge and suction ends.

The suction end has provisions for the installation of a standard small HVA 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713