Attendance counter

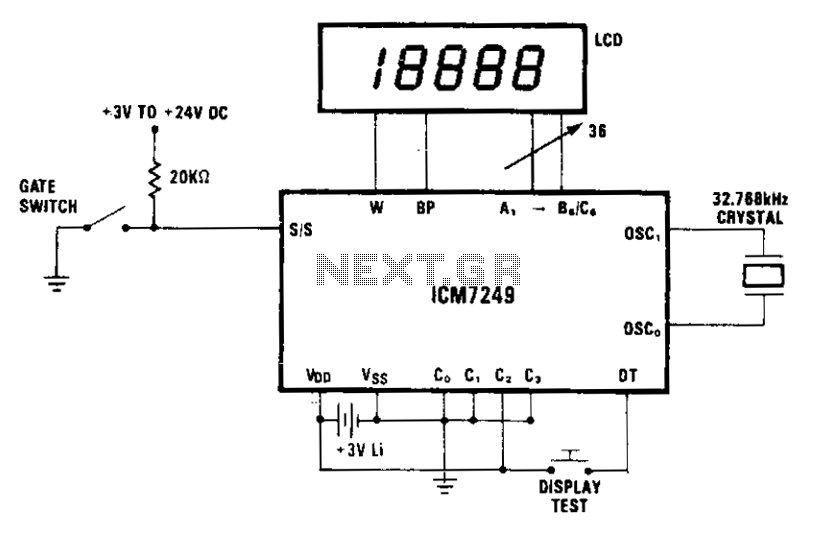

The display indicates each increment. In mode 2, external debouncing of the gate switch is unnecessary, provided that the switch bounce duration is less than 35 ms. The 3 V lithium battery can be replaced without interrupting operation if a suitable capacitor is connected in parallel with it. To minimize current drain, the display should be disconnected, if feasible, during this process. The capacitor must be sufficiently large to store charge for the duration required to physically replace the battery (t = VC/I). A 100 µF capacitor, initially charged to 3 V, will supply a current of 1.0 µA for 50 seconds before its voltage drops to 2.5 V, which is the minimum operating voltage for the ICM7249. Prior to battery removal, the capacitor should be connected in parallel across the VDD and GND terminals. After replacing the battery, the capacitor can be removed, and the display can be reconnected.

The circuit described operates with a display that increments based on input signals. In mode 2, it effectively eliminates the need for external debouncing circuitry for the gate switch, assuming the switch bounce duration is below 35 ms. This feature simplifies the design and reduces component count, making the circuit more efficient.

The power supply for the circuit is a 3 V lithium battery, which can be replaced without disrupting the operation of the display. This is achieved by using a capacitor connected in parallel with the battery. The capacitor serves as a temporary power source, allowing the circuit to remain powered while the battery is being replaced. It is crucial to select a capacitor with adequate capacitance to ensure that it can store sufficient charge for the time required to replace the battery.

A 100 µF capacitor is specified, which, when charged to 3 V, can deliver a current of 1.0 µA for approximately 50 seconds before its voltage drops to the minimum operating threshold of 2.5 V for the ICM7249 integrated circuit. This ensures that the display remains operational during the battery replacement process.

To implement this procedure correctly, the capacitor should be connected across the VDD and GND terminals before the battery is removed. This connection allows the capacitor to start discharging and providing power to the circuit immediately after the battery is disconnected. Once the new battery is installed, the capacitor can be safely removed, and the display can be reconnected to the circuit.

This design approach enhances reliability by allowing for maintenance without complete power loss, thereby preventing data loss or operational interruptions during battery changes. It is recommended to ensure that the capacitor is properly rated for the application to avoid any potential damage to the circuit components.The display shows each increment. By using mode 2, external debouncing of the gate switch is unnecessary, provided the switch bounce is less than 35ms. The 3 V lithium battery can be replaced without disturbing operation if a suitable capacitor is connected in parallel with it.

The display should be disconnected, if possible, during the procedure to minimize current drain. The capacitor should be large enough to store charge for the amount of time needed to physically replace the battery (t = VC/1). A 100 ^F capacitor initially charged to 3 V will supply a current of 1.0 µ A for 50 seconds before its voltage drops to 2.5 V, which is the minimum operating voltage for the ICM7249.

Before the battery is removed, the capacitor should be placed in parallel, across the VDD and GND terminals. After the battery is replaced, the capacitor can be removed and the display reconnected. 🔗 External reference

The circuit described operates with a display that increments based on input signals. In mode 2, it effectively eliminates the need for external debouncing circuitry for the gate switch, assuming the switch bounce duration is below 35 ms. This feature simplifies the design and reduces component count, making the circuit more efficient.

The power supply for the circuit is a 3 V lithium battery, which can be replaced without disrupting the operation of the display. This is achieved by using a capacitor connected in parallel with the battery. The capacitor serves as a temporary power source, allowing the circuit to remain powered while the battery is being replaced. It is crucial to select a capacitor with adequate capacitance to ensure that it can store sufficient charge for the time required to replace the battery.

A 100 µF capacitor is specified, which, when charged to 3 V, can deliver a current of 1.0 µA for approximately 50 seconds before its voltage drops to the minimum operating threshold of 2.5 V for the ICM7249 integrated circuit. This ensures that the display remains operational during the battery replacement process.

To implement this procedure correctly, the capacitor should be connected across the VDD and GND terminals before the battery is removed. This connection allows the capacitor to start discharging and providing power to the circuit immediately after the battery is disconnected. Once the new battery is installed, the capacitor can be safely removed, and the display can be reconnected to the circuit.

This design approach enhances reliability by allowing for maintenance without complete power loss, thereby preventing data loss or operational interruptions during battery changes. It is recommended to ensure that the capacitor is properly rated for the application to avoid any potential damage to the circuit components.The display shows each increment. By using mode 2, external debouncing of the gate switch is unnecessary, provided the switch bounce is less than 35ms. The 3 V lithium battery can be replaced without disturbing operation if a suitable capacitor is connected in parallel with it.

The display should be disconnected, if possible, during the procedure to minimize current drain. The capacitor should be large enough to store charge for the amount of time needed to physically replace the battery (t = VC/1). A 100 ^F capacitor initially charged to 3 V will supply a current of 1.0 µ A for 50 seconds before its voltage drops to 2.5 V, which is the minimum operating voltage for the ICM7249.

Before the battery is removed, the capacitor should be placed in parallel, across the VDD and GND terminals. After the battery is replaced, the capacitor can be removed and the display reconnected. 🔗 External reference