Automated Water Tank Filler

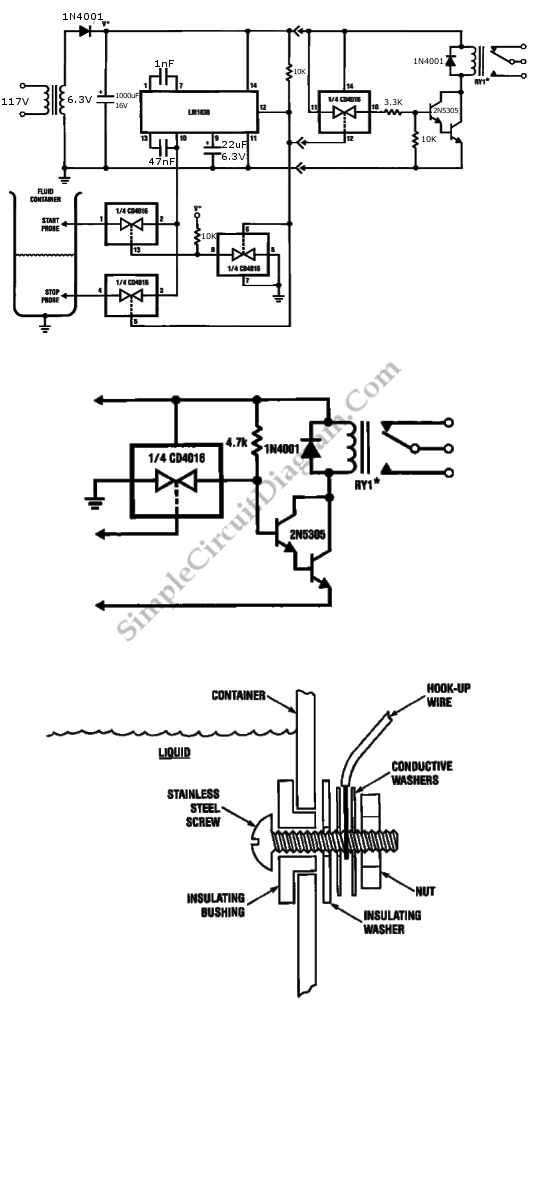

This circuit can be utilized to maintain the water level in the header tank within specified limits. It employs a 3HP submersible bore pump that features a high starting capacity.

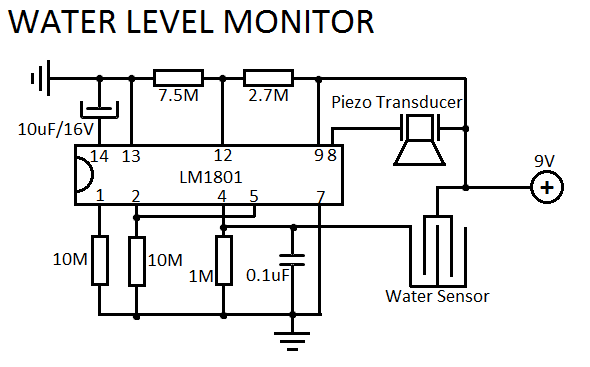

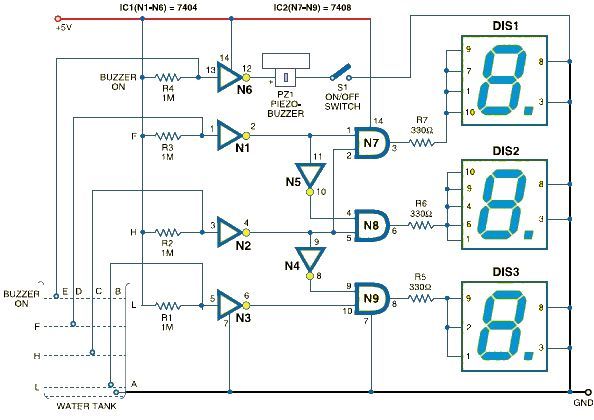

The proposed circuit operates by continuously monitoring the water level in the header tank and controlling the operation of the submersible bore pump accordingly. The system typically includes water level sensors, such as float switches or pressure transducers, that detect the water level at predetermined points.

When the water level falls below a set threshold, the sensor activates the pump, allowing water to fill the tank until the upper threshold is reached. Conversely, if the water level exceeds the upper limit, the circuit will deactivate the pump to prevent overflow.

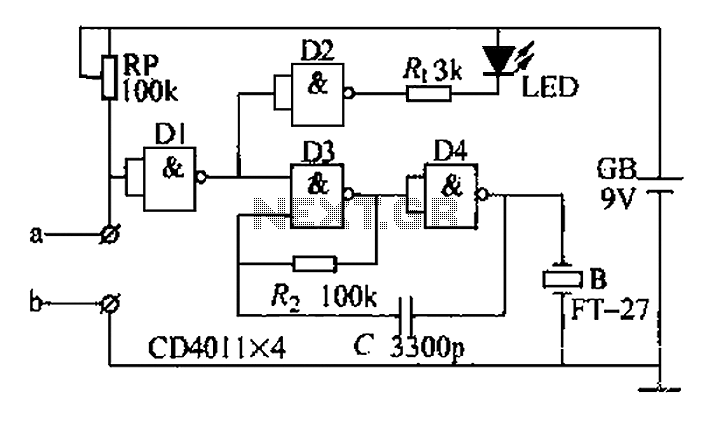

Key components of this circuit may include a microcontroller or relay system to process the signals from the sensors and control the pump operation. Additionally, protective devices such as circuit breakers or fuses can be integrated to safeguard against electrical faults.

The design should also consider the power supply requirements for the pump and control circuitry, ensuring that appropriate voltage and current ratings are maintained. Adequate wiring and connectors must be selected to handle the load of the 3HP pump, which may require specific gauge wiring to prevent overheating and voltage drops.

In summary, this circuit is essential for automated water level control in a header tank system, providing efficient operation of the submersible bore pump while ensuring that water levels remain within safe and functional limits.We can use the circuit below to maintain the level of water in the header tank within prescribed limits. A 3HP submersible bore pump which has a high starting.. 🔗 External reference

The proposed circuit operates by continuously monitoring the water level in the header tank and controlling the operation of the submersible bore pump accordingly. The system typically includes water level sensors, such as float switches or pressure transducers, that detect the water level at predetermined points.

When the water level falls below a set threshold, the sensor activates the pump, allowing water to fill the tank until the upper threshold is reached. Conversely, if the water level exceeds the upper limit, the circuit will deactivate the pump to prevent overflow.

Key components of this circuit may include a microcontroller or relay system to process the signals from the sensors and control the pump operation. Additionally, protective devices such as circuit breakers or fuses can be integrated to safeguard against electrical faults.

The design should also consider the power supply requirements for the pump and control circuitry, ensuring that appropriate voltage and current ratings are maintained. Adequate wiring and connectors must be selected to handle the load of the 3HP pump, which may require specific gauge wiring to prevent overheating and voltage drops.

In summary, this circuit is essential for automated water level control in a header tank system, providing efficient operation of the submersible bore pump while ensuring that water levels remain within safe and functional limits.We can use the circuit below to maintain the level of water in the header tank within prescribed limits. A 3HP submersible bore pump which has a high starting.. 🔗 External reference