Automatic winding circuitry

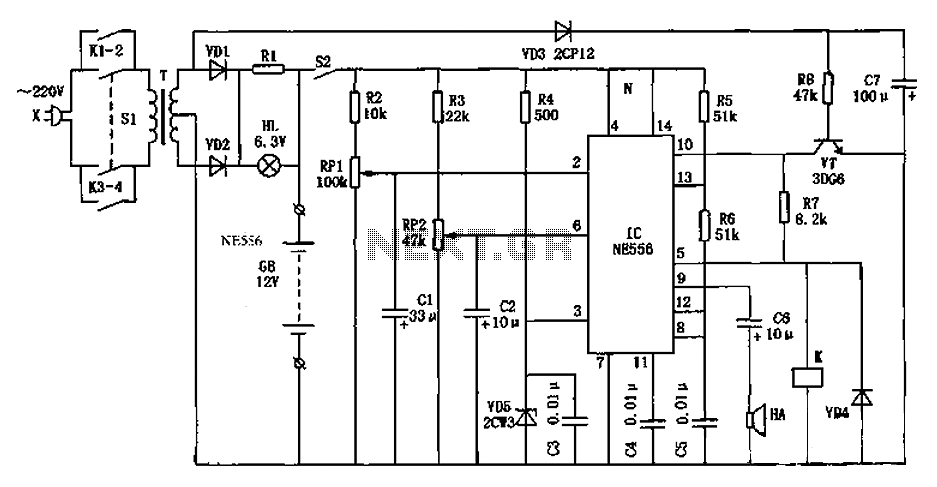

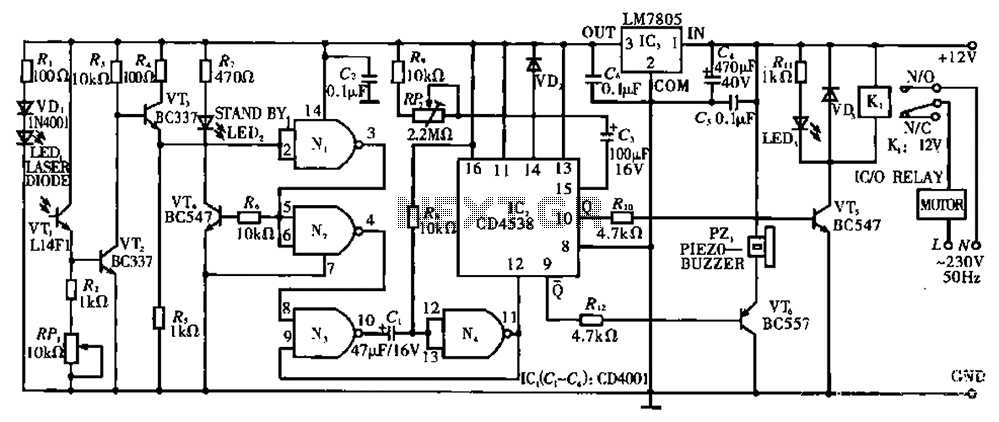

This document describes an electronic winding machine with manual, electric, and semi-automatic features. The specific example highlighted includes an electronic counting function that assists users in managing motor windings. The circuit design consists of various components as illustrated in the provided figures. The optical sensor circuit is made up of resistors and optical couplers, which facilitate counting through addition and subtraction mechanisms. The shaping circuit utilizes a Schmitt trigger NAND gate integrated circuit, while the plus/minus recognition is achieved through D flip-flop circuits. A four-digit counter is integrated with a reset button and a digital display for user feedback. The circuit allows for the adjustment of sensitivity through specific resistors, enhancing the machine's capability to count multiple winding coils simultaneously, thereby improving production efficiency.

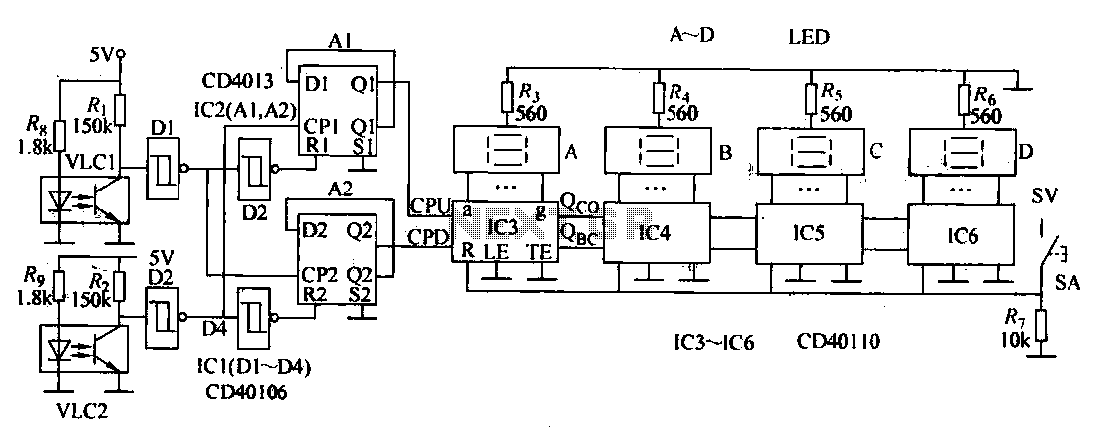

The electronic winding machine incorporates a sophisticated design tailored for efficient operation in winding applications. The core of the system is the optical sensor circuit, which employs resistors (R1, R2, R3, R4) and optical couplers (VLC1, VLC2) to detect the winding process. This circuit is divided into two main functions: the addition counting circuit and the subtraction counting circuit. The addition circuit is triggered by the first optical sensor (VLC1), which detects the winding motion and activates the counter to increment the count. Conversely, the subtraction circuit is initiated by the second optical sensor (VLC2), which is used for reverse winding operations, allowing the system to decrement the count as needed.

The shaping circuit is constructed using a Schmitt trigger NAND gate integrated circuit (IC1), which stabilizes the signal and ensures reliable operation during the counting process. The plus/minus recognition circuit employs two D flip-flops (IC2) to manage the direction of the count, allowing for seamless transitions between winding and unwinding operations.

The four-digit counter is a crucial feature, consisting of a counter/decoder integrated circuit (IC3 to IC6) that drives a digital display (LEDs A to D). This display provides real-time feedback to the operator regarding the number of turns completed. The reset functionality is integrated into the circuit, allowing the operator to clear the count as needed. The system is designed for user-friendly operation, with adjustments available for the resistors (Ri, Rz, R3) to fine-tune the sensitivity of the optical sensors, thereby accommodating various winding materials and conditions.

Overall, this electronic winding machine exemplifies advanced engineering design, combining electronic counting capabilities with mechanical winding processes to enhance production efficiency and accuracy in motor winding applications.Electronic Winder points manual, electric, semi-automatic winding machine variety, this example describes a winding machine with electronic counting feature that lets users coi led, used motor windings. (1) The circuit Winder shape as shown in FIG. 7-la. By the optical sensor circuit, shaping circuit, plus/minus recognition circuit and four-digit counter circuit, as shown in Figure 7-lb. Photosensor circuit consists of resistors Ri, R2, flat, R, and optical coupler VI-C1, VI4C2 composition.

R., R. And VLC1 composition adder counting sensor circuit. Rz, R9 and VLC2 composition subtraction counting sensor circuit. South Sixth shaping circuit Schmitt trigger NAND gate integrated circuit lCl internal rhyme D1-D4 constitute. Plus/minus recognition by the two D flip-flop circuit IC2 internal trigger Al, A2 components. Four-digit counter by the resistors R3-R, reset button S, counter/decoder integrated circuit IC3 ~ IC6 and LED digital display A ~ D components.

(2) The circuit diagram used to answer it SA, to reset the counter is cleared, then the input Dl, D3 and D2, D4 of the output terminal are high. Oi, Q2 output of IC2 is low. 10 does not count. When the winding machine forward (addition count), the rectangular aperture winding turntable so VLC1 first trigger, so D1 output high.

D2 output low Subsequently VLC2 trigger, D3 output level as the end of IC2 CP1 trigger pulse, A1 stupid turn in lC3 {the CPU side to join the count pulse, the counter starts counting the addition. Similarly, if the winding reverses, then. VLC2 first trigger work, VLC1 trigger work. AZ flip, count pulses IC3 provide the CPD, subtraction counter starts counting. Adjustment Ri wind resistance, can change VLC1 sensitivity. Adjustment Rz and R, the resistance, can change VLC2 sensitivity. Automatic winding machine has counted five simultaneous winding coils and other functions, can improve production efficiency.

The electronic winding machine incorporates a sophisticated design tailored for efficient operation in winding applications. The core of the system is the optical sensor circuit, which employs resistors (R1, R2, R3, R4) and optical couplers (VLC1, VLC2) to detect the winding process. This circuit is divided into two main functions: the addition counting circuit and the subtraction counting circuit. The addition circuit is triggered by the first optical sensor (VLC1), which detects the winding motion and activates the counter to increment the count. Conversely, the subtraction circuit is initiated by the second optical sensor (VLC2), which is used for reverse winding operations, allowing the system to decrement the count as needed.

The shaping circuit is constructed using a Schmitt trigger NAND gate integrated circuit (IC1), which stabilizes the signal and ensures reliable operation during the counting process. The plus/minus recognition circuit employs two D flip-flops (IC2) to manage the direction of the count, allowing for seamless transitions between winding and unwinding operations.

The four-digit counter is a crucial feature, consisting of a counter/decoder integrated circuit (IC3 to IC6) that drives a digital display (LEDs A to D). This display provides real-time feedback to the operator regarding the number of turns completed. The reset functionality is integrated into the circuit, allowing the operator to clear the count as needed. The system is designed for user-friendly operation, with adjustments available for the resistors (Ri, Rz, R3) to fine-tune the sensitivity of the optical sensors, thereby accommodating various winding materials and conditions.

Overall, this electronic winding machine exemplifies advanced engineering design, combining electronic counting capabilities with mechanical winding processes to enhance production efficiency and accuracy in motor winding applications.Electronic Winder points manual, electric, semi-automatic winding machine variety, this example describes a winding machine with electronic counting feature that lets users coi led, used motor windings. (1) The circuit Winder shape as shown in FIG. 7-la. By the optical sensor circuit, shaping circuit, plus/minus recognition circuit and four-digit counter circuit, as shown in Figure 7-lb. Photosensor circuit consists of resistors Ri, R2, flat, R, and optical coupler VI-C1, VI4C2 composition.

R., R. And VLC1 composition adder counting sensor circuit. Rz, R9 and VLC2 composition subtraction counting sensor circuit. South Sixth shaping circuit Schmitt trigger NAND gate integrated circuit lCl internal rhyme D1-D4 constitute. Plus/minus recognition by the two D flip-flop circuit IC2 internal trigger Al, A2 components. Four-digit counter by the resistors R3-R, reset button S, counter/decoder integrated circuit IC3 ~ IC6 and LED digital display A ~ D components.

(2) The circuit diagram used to answer it SA, to reset the counter is cleared, then the input Dl, D3 and D2, D4 of the output terminal are high. Oi, Q2 output of IC2 is low. 10 does not count. When the winding machine forward (addition count), the rectangular aperture winding turntable so VLC1 first trigger, so D1 output high.

D2 output low Subsequently VLC2 trigger, D3 output level as the end of IC2 CP1 trigger pulse, A1 stupid turn in lC3 {the CPU side to join the count pulse, the counter starts counting the addition. Similarly, if the winding reverses, then. VLC2 first trigger work, VLC1 trigger work. AZ flip, count pulses IC3 provide the CPD, subtraction counter starts counting. Adjustment Ri wind resistance, can change VLC1 sensitivity. Adjustment Rz and R, the resistance, can change VLC2 sensitivity. Automatic winding machine has counted five simultaneous winding coils and other functions, can improve production efficiency.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713