Automotive LED Timing Light

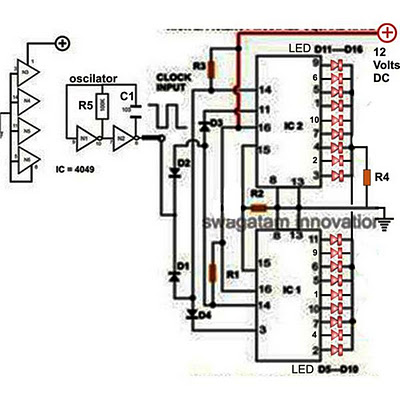

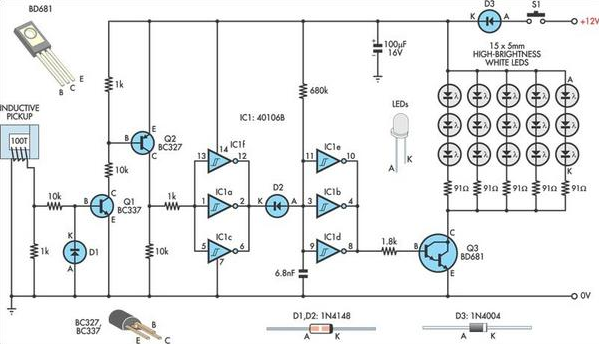

A useful timing strobe can be constructed using high-brightness LEDs and a few common components. Ignition pulses from the number 1 cylinder high-tension lead are used to trigger the circuit via a homemade inductive pickup. Transistors Q1 and Q2 buffer and amplify the pulses from the pickup, which then drive the inputs of three Schmitt-trigger inverters (IC1a, IC1c, and IC1f). Each positive pulse at the inverter inputs causes a low pulse at their outputs, forward-biasing D2 and immediately discharging the 6.8nF capacitor. When the capacitor is discharged, the inputs of the second bank of three inverters (IC1b, IC1d, and IC1e) see a logic low level, so their outputs go high, driving Q3 into conduction and powering the LED array. After the pulse ends, the inverter outputs from IC1a, IC1c, and IC1f return high, reverse-biasing D2. However, it takes some time for the 6.8nF capacitor to charge to the logic high threshold voltage of the inverters' inputs, effectively stretching the initial pulse width and lighting the LEDs for the required amount of time. The pickup can be salvaged from an old Xenon timing light or made from a C-type ferrite or powered iron core large enough to fit around a high-tension lead. Some experimentation will be required to determine the number of turns needed for reliable triggering. About 100 turns of light-gauge wire proved sufficient on the prototype. A cleat is used to close the magnetic path around the lead and is held in place with a large battery clip. Miniature screened microphone cable can be used to connect the pickup to the circuit to prevent interference from other sources.

This timing strobe circuit utilizes high-brightness LEDs as the primary visual output, activated by ignition pulses from the number 1 cylinder of an engine. The circuit is initiated using a homemade inductive pickup, which detects the high-tension lead's electromagnetic field. The output from the pickup is first buffered and amplified by transistors Q1 and Q2. This amplification ensures that the subsequent signals are strong enough to drive the inputs of the Schmitt-trigger inverters, specifically IC1a, IC1c, and IC1f.

The Schmitt-trigger inverters are critical for converting the pulsed input signals into a clean output. Each inverter generates a low output pulse in response to a positive input pulse, which forward-biases diode D2. This action discharges the 6.8nF capacitor immediately. As the capacitor discharges, it creates a logic low condition at the inputs of the second set of inverters (IC1b, IC1d, and IC1e). Consequently, these inverters output a high signal, which activates transistor Q3, thereby powering the LED array.

The timing of the LED illumination is controlled by the capacitor's charge and discharge cycle. After the initial pulse from the ignition, the outputs of IC1a, IC1c, and IC1f return to a high state, reverse-biasing D2. The capacitor's charging time to reach the logic high threshold of the inverters effectively lengthens the duration of the LED illumination, providing a strobe effect that can be adjusted based on the capacitor's characteristics.

For the inductive pickup, it is recommended to use a C-type ferrite or powered iron core, which should be wrapped with approximately 100 turns of light-gauge wire to ensure effective signal capture. The design may require some adjustments to the number of turns based on experimental results to achieve optimal triggering performance. To maintain signal integrity and minimize interference, a miniature screened microphone cable is advisable for connecting the pickup to the circuit. This setup provides a robust and effective method for visual timing indications in automotive applications.A useful timing strobe can be constructed using high-brightness LEDs and a few common components. Ignition pulses from the number 1 cylinder high-tension lead are used to trigger the circuit via a home-made inductive pickup. Transistors Q1 & Q2 buffer and amplify the pulses from the pickup, which then drive the inputs of three Schmitt-trigger inve

rters (IC1a, IC1c & IC1f). Each positive pulse at the inverter inputs causes a low pulse at their outputs, forward-biasing D2 and immediately discharging the 6. 8nF capacitor. When the capacitor is discharged, the inputs of the second bank of three inverters (IC1b, IC1d & IC1e) see a logic low level, so their outputs go high, driving Q3 into conduction and powering the LED array.

After the pulse ends, the IC1a, IC1c & IC1f inverter outputs return high, reverse biasing D2. However, it takes some time for the 6. 8nF capacitor to charge to the logic high threshold voltage of the inverters` inputs, effectively stretching the initial pulse width and lighting the LEDs for the required amount of time. The pickup can be salvaged from an old Xenon timing light or made up from a C type ferrite or powered iron core large enough to fit around a HT lead.

Some experimentation will be required to determine the number of turns required to achieve reliable triggering. About 100 turns of light-gauge wire proved sufficient on the prototype. A cleat is used to close the magnetic path around the lead and is held in place with a large battery clip.

Miniature screened microphone cable can be used to connect the pickup to the circuit, to prevent interference from other sources. 🔗 External reference

This timing strobe circuit utilizes high-brightness LEDs as the primary visual output, activated by ignition pulses from the number 1 cylinder of an engine. The circuit is initiated using a homemade inductive pickup, which detects the high-tension lead's electromagnetic field. The output from the pickup is first buffered and amplified by transistors Q1 and Q2. This amplification ensures that the subsequent signals are strong enough to drive the inputs of the Schmitt-trigger inverters, specifically IC1a, IC1c, and IC1f.

The Schmitt-trigger inverters are critical for converting the pulsed input signals into a clean output. Each inverter generates a low output pulse in response to a positive input pulse, which forward-biases diode D2. This action discharges the 6.8nF capacitor immediately. As the capacitor discharges, it creates a logic low condition at the inputs of the second set of inverters (IC1b, IC1d, and IC1e). Consequently, these inverters output a high signal, which activates transistor Q3, thereby powering the LED array.

The timing of the LED illumination is controlled by the capacitor's charge and discharge cycle. After the initial pulse from the ignition, the outputs of IC1a, IC1c, and IC1f return to a high state, reverse-biasing D2. The capacitor's charging time to reach the logic high threshold of the inverters effectively lengthens the duration of the LED illumination, providing a strobe effect that can be adjusted based on the capacitor's characteristics.

For the inductive pickup, it is recommended to use a C-type ferrite or powered iron core, which should be wrapped with approximately 100 turns of light-gauge wire to ensure effective signal capture. The design may require some adjustments to the number of turns based on experimental results to achieve optimal triggering performance. To maintain signal integrity and minimize interference, a miniature screened microphone cable is advisable for connecting the pickup to the circuit. This setup provides a robust and effective method for visual timing indications in automotive applications.A useful timing strobe can be constructed using high-brightness LEDs and a few common components. Ignition pulses from the number 1 cylinder high-tension lead are used to trigger the circuit via a home-made inductive pickup. Transistors Q1 & Q2 buffer and amplify the pulses from the pickup, which then drive the inputs of three Schmitt-trigger inve

rters (IC1a, IC1c & IC1f). Each positive pulse at the inverter inputs causes a low pulse at their outputs, forward-biasing D2 and immediately discharging the 6. 8nF capacitor. When the capacitor is discharged, the inputs of the second bank of three inverters (IC1b, IC1d & IC1e) see a logic low level, so their outputs go high, driving Q3 into conduction and powering the LED array.

After the pulse ends, the IC1a, IC1c & IC1f inverter outputs return high, reverse biasing D2. However, it takes some time for the 6. 8nF capacitor to charge to the logic high threshold voltage of the inverters` inputs, effectively stretching the initial pulse width and lighting the LEDs for the required amount of time. The pickup can be salvaged from an old Xenon timing light or made up from a C type ferrite or powered iron core large enough to fit around a HT lead.

Some experimentation will be required to determine the number of turns required to achieve reliable triggering. About 100 turns of light-gauge wire proved sufficient on the prototype. A cleat is used to close the magnetic path around the lead and is held in place with a large battery clip.

Miniature screened microphone cable can be used to connect the pickup to the circuit, to prevent interference from other sources. 🔗 External reference