Bachmann Sound Tips

The Bachmann Big Hauler locomotive has significantly improved in appearance, reliability, and noise level over the past few years. However, the sound system remains basic, providing a poor imitation of exhaust sounds in the form of a chuff synchronized with the engine drivers. While it lacks the quality of modern digital sound systems, it is possible to enhance the sound with minimal components and effort. The exhaust sound profile in the unmodified system is too sharp. By adding one resistor and one capacitor to the sound board in the tender, the attack and delay of the exhaust beat can be softened. The system's frequency response results in a tinny sound, which can be improved with two additional components to enhance low-frequency response. The sound system generates only two beats per driver revolution, whereas real steam locomotives produce four. Adding two short wires or resistors to the sound drum on the front axle can create the additional beats. The system also tends to hiss continuously when it stops with the sound contacts closed. A simple track power sensor can deactivate the sound when track power is lost. These modifications can be implemented independently and are fully reversible. The addition of these changes significantly enhances the Bachmann Big Hauler, improvements that should be considered for future models. Real steam locomotives can produce variable amplitude beats during forward and backward piston strokes, often due to valve timing adjustments or mechanical wear. This can result in a "CHUFF CHUFF chuff chuff" sound sequence, which is more engaging than a constant exhaust sound. Such variable exhaust sounds can also be achieved through simple modifications to the sound drum. The sound generator circuit board is located in the tender of the locomotive, consisting of a noise diode and a high-gain amplifier to drive the speaker. The sound system is activated by the sound drum in the locomotive, which connects or disconnects a tender-mounted 9-volt battery. For RC Big Haulers, the switched 9-volt power comes from the locomotive battery. The described modifications are compatible with both versions. In the RC Big Hauler, the sound circuit is integrated into the motor controller board located in the engine smokebox, occupying the rear third of the circuit board. Accessing the sound board involves removing four screws from the tender's bottom to detach the tender body, followed by unscrewing the coal load. The coal load can be left in place during reinstallation. The modification is easier with the tender body attached since it also serves as the battery holder. The black wire leading to the locomotive should be located and unsoldered. One end of a 10 to 22-ohm resistor and the positive lead of a 33 to 50 microfarad capacitor should be connected to the corresponding pad on the board. The black wire can then be reattached to the other end of the resistor, while the negative lead of the capacitor connects to the pad marked with a "G," which is linked to the red wire going to the locomotive.

The circuit modifications described enhance the auditory experience of the Bachmann Big Hauler locomotive, creating a more realistic sound profile that mimics the characteristics of actual steam locomotives. The addition of the resistor and capacitor alters the sound wave characteristics, softening the sharpness of the original sound and improving the low-frequency response. This results in a fuller sound that is more representative of steam engine exhaust.

The implementation of additional components to generate the missing beats per revolution is crucial for achieving a more authentic sound. By ensuring that the sound system produces four beats per driver revolution, the locomotive can replicate the rhythmic chuffing associated with real steam engines. The use of a track power sensor to disable the sound when the locomotive stops is a practical enhancement that prevents unwanted noise and improves the overall user experience.

Furthermore, the modifications maintain reversibility, allowing users to restore the original sound system if desired. This flexibility encourages experimentation and personalization, enabling hobbyists to tailor the sound characteristics of their locomotives to suit individual preferences.

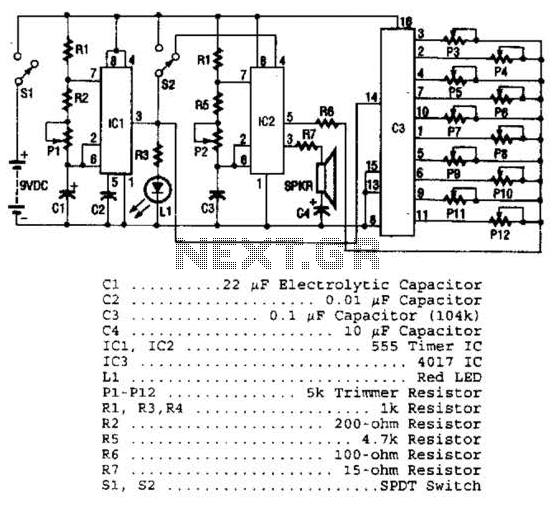

The schematic diagram of the sound generator circuit board illustrates the integration of components, including the noise diode and amplifier, essential for sound production. The design emphasizes simplicity and efficiency, reflecting the overall philosophy of enhancing the existing system without extensive alterations. The accessibility of the sound board and the straightforward nature of the modifications make this an attractive option for hobbyists seeking to enhance their Bachmann Big Hauler locomotives.The Bachmann Big Hauler locomotive has improved greatly over the last few years in appearance, reliability and noise level. However one thing that hasn`t improved is the very basic sound system. The system provides a pretty poor facsimile of an exhaust sound in the form of a "chuff" that is synchronized to the engine drivers.

The system can`t prov ide anything near the pleasing sound of new digital sound systems, but for less than a dollar`s worth of parts and a few minutes labor, the sound can be materially improved. The "profile" of the exhaust sound is much too sharp in an unmodified sound system. Addition of one resistor and one capacitor to the sound board in the tender will soften the attack and delay of the exhaust beat.

The frequency response of the system leads to a tinny sound, two more parts can improve the low frequency response. The sound system generates only two beats per driver revolution while real steam locomotives have four exhaust beats per revolution.

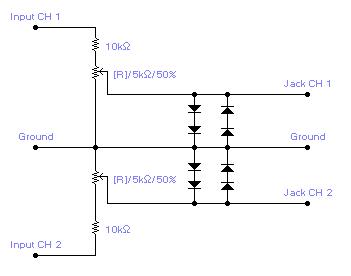

Addition of two short wires or resistors to the sound drum on the front axle in the locomotive adds the other two beats. The system has the annoying tendency to sometimes hiss continuously when it stops with the sound contacts closed.

A simple track power sensor can shut it off when the track power goes away. Each of these changes can be made independently and all are completely reversible. I find that the addition of these simple modifications makes a material improvement to the Bachmann Big Hauler, ones that Bachmann should incorporate in some future model. Often real steam locomotives will generate beats of different amplitude on the forward and backward piston strokes.

This is sometimes caused by the engineer adjusting the valve timing to modify locomotive performance, especially at low speeds, but more often it is caused by a tired and worn valves or a number of other problems. This can result in a "CHUFF CHUFF chuff chuff" sound sequence. While this variable exhaust sound usually doesn`t happen all the time, it is more interesting than steady and unchanging exhaust sounds.

This sound sequence, or any other repeating four pulse beat can also be accommodated by simple and reversible modifications to the sound drum. The sound generator circuit board sits in the tender of the locomotive. A schematic diagram of the circuit is shown below. The circuit consists of a noise diode and a high gain amplifier to drive the speaker. The sound system is switched on and off by the sound drum in the locomotive which either connects or disconnects a tender mounted 9 volt battery.

On RC Big Haulers, switched 9 volt power comes from the locomotive battery. The modifications described here will work for either version. In the RC Big Hauler, the sound circuit is part of the motor controller board in the engine smokebox. The circuit is the same and it occupies the rearmost third of the circuit board. Gain access the sound board by removing the four screws on the bottom of the tender that hold on the tender body and then remove the body.

Remove the two screws that attach the coal load and drop the screws into your junk box. The coal load will stay in place by itself when you reinstall it later. Reinstall the tender body and work through the hole exposed by the removed coal load. Its actually easier to do this mod with the tender body installed because the tender body is the battery holder too. Locate the black wire that leads to the locomotive as shown in the photo. It should go a pad on the board that also has a white wire leading to the battery. Unsolder the black wire. Install one end of a 10 to 22 ohm resistor and the positive lead of a 33 to 50 microfarad capacitor to this pad.

Solder the black wire back to the other end of the resistor. Solder the negative lead of the capacitor to pad which is connected to the red wire that goes to the locomotive (this pad is marked with a "G"). Put the battery back in and the 🔗 External reference

The circuit modifications described enhance the auditory experience of the Bachmann Big Hauler locomotive, creating a more realistic sound profile that mimics the characteristics of actual steam locomotives. The addition of the resistor and capacitor alters the sound wave characteristics, softening the sharpness of the original sound and improving the low-frequency response. This results in a fuller sound that is more representative of steam engine exhaust.

The implementation of additional components to generate the missing beats per revolution is crucial for achieving a more authentic sound. By ensuring that the sound system produces four beats per driver revolution, the locomotive can replicate the rhythmic chuffing associated with real steam engines. The use of a track power sensor to disable the sound when the locomotive stops is a practical enhancement that prevents unwanted noise and improves the overall user experience.

Furthermore, the modifications maintain reversibility, allowing users to restore the original sound system if desired. This flexibility encourages experimentation and personalization, enabling hobbyists to tailor the sound characteristics of their locomotives to suit individual preferences.

The schematic diagram of the sound generator circuit board illustrates the integration of components, including the noise diode and amplifier, essential for sound production. The design emphasizes simplicity and efficiency, reflecting the overall philosophy of enhancing the existing system without extensive alterations. The accessibility of the sound board and the straightforward nature of the modifications make this an attractive option for hobbyists seeking to enhance their Bachmann Big Hauler locomotives.The Bachmann Big Hauler locomotive has improved greatly over the last few years in appearance, reliability and noise level. However one thing that hasn`t improved is the very basic sound system. The system provides a pretty poor facsimile of an exhaust sound in the form of a "chuff" that is synchronized to the engine drivers.

The system can`t prov ide anything near the pleasing sound of new digital sound systems, but for less than a dollar`s worth of parts and a few minutes labor, the sound can be materially improved. The "profile" of the exhaust sound is much too sharp in an unmodified sound system. Addition of one resistor and one capacitor to the sound board in the tender will soften the attack and delay of the exhaust beat.

The frequency response of the system leads to a tinny sound, two more parts can improve the low frequency response. The sound system generates only two beats per driver revolution while real steam locomotives have four exhaust beats per revolution.

Addition of two short wires or resistors to the sound drum on the front axle in the locomotive adds the other two beats. The system has the annoying tendency to sometimes hiss continuously when it stops with the sound contacts closed.

A simple track power sensor can shut it off when the track power goes away. Each of these changes can be made independently and all are completely reversible. I find that the addition of these simple modifications makes a material improvement to the Bachmann Big Hauler, ones that Bachmann should incorporate in some future model. Often real steam locomotives will generate beats of different amplitude on the forward and backward piston strokes.

This is sometimes caused by the engineer adjusting the valve timing to modify locomotive performance, especially at low speeds, but more often it is caused by a tired and worn valves or a number of other problems. This can result in a "CHUFF CHUFF chuff chuff" sound sequence. While this variable exhaust sound usually doesn`t happen all the time, it is more interesting than steady and unchanging exhaust sounds.

This sound sequence, or any other repeating four pulse beat can also be accommodated by simple and reversible modifications to the sound drum. The sound generator circuit board sits in the tender of the locomotive. A schematic diagram of the circuit is shown below. The circuit consists of a noise diode and a high gain amplifier to drive the speaker. The sound system is switched on and off by the sound drum in the locomotive which either connects or disconnects a tender mounted 9 volt battery.

On RC Big Haulers, switched 9 volt power comes from the locomotive battery. The modifications described here will work for either version. In the RC Big Hauler, the sound circuit is part of the motor controller board in the engine smokebox. The circuit is the same and it occupies the rearmost third of the circuit board. Gain access the sound board by removing the four screws on the bottom of the tender that hold on the tender body and then remove the body.

Remove the two screws that attach the coal load and drop the screws into your junk box. The coal load will stay in place by itself when you reinstall it later. Reinstall the tender body and work through the hole exposed by the removed coal load. Its actually easier to do this mod with the tender body installed because the tender body is the battery holder too. Locate the black wire that leads to the locomotive as shown in the photo. It should go a pad on the board that also has a white wire leading to the battery. Unsolder the black wire. Install one end of a 10 to 22 ohm resistor and the positive lead of a 33 to 50 microfarad capacitor to this pad.

Solder the black wire back to the other end of the resistor. Solder the negative lead of the capacitor to pad which is connected to the red wire that goes to the locomotive (this pad is marked with a "G"). Put the battery back in and the 🔗 External reference