Back emf motor speed control

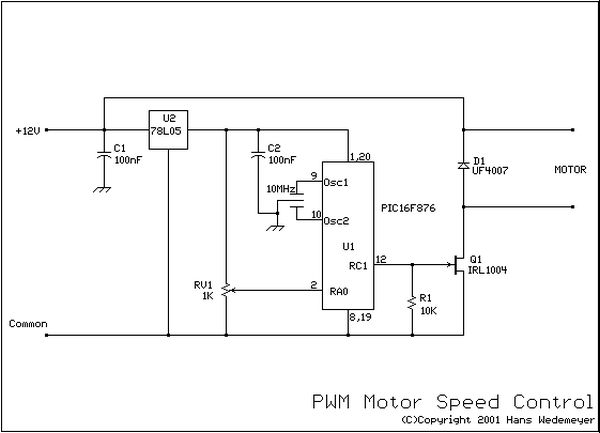

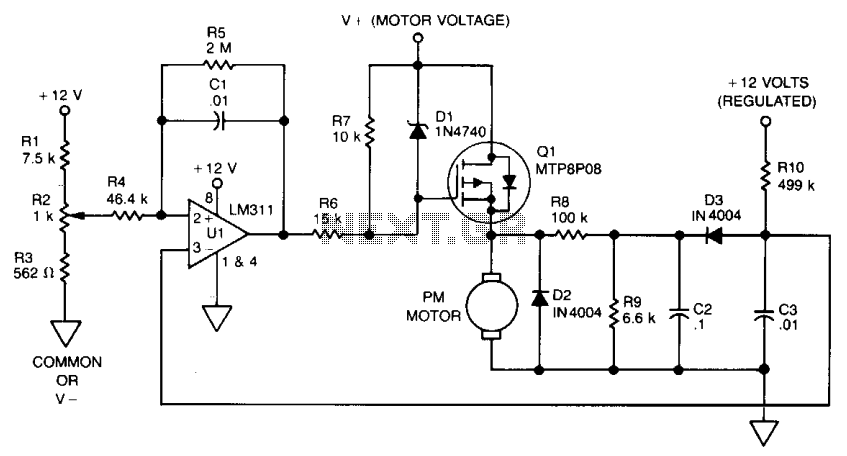

The use of power MOSFETs facilitates a direct interface between logic and motor power, enabling circuit simplicity and high efficiency. This speed control circuit can be implemented on a 22-pin, double-sided, 3.5 x 4-inch printed circuit board (PCB). A 12 V control supply and a TRW BL11, 30 V motor are utilized; with minor modifications, other motor and control voltages can be accommodated. For instance, a single 24 V rail could provide both control and motor voltages. Motor and control voltages are kept separate in this design because CMOS logic is employed to start, stop, reverse, and oscillate the motor with a variable delay between reversals. Motor speed is determined by potentiometer R2, which applies a corresponding DC voltage to the positive input of comparator U1. The output from U1 is connected to the TMOS device MTP8P08 (Q1). Zener diode D1 limits the drive to Q1. The output of Q1 drives the permanent magnet motor. Back EMF is generated from the motor through the network consisting of R8, R9, R10, C2, C3, and D3, which is applied to the negative input of comparator U1.

The circuit design leverages the advantages of power MOSFETs, allowing for efficient control of the motor's speed and direction. The incorporation of a 22-pin double-sided PCB enhances the circuit's compactness and facilitates efficient layout and routing. The choice of a 12 V control supply alongside a 30 V motor provides flexibility, allowing the circuit to be adapted for various applications with minimal alterations.

The speed control mechanism is centered around potentiometer R2, which functions as a variable resistor, enabling the user to adjust the voltage supplied to the positive input of comparator U1. Comparator U1 compares this voltage with the feedback voltage derived from the motor's back EMF. The feedback network, comprising resistors R8, R9, R10, capacitors C2 and C3, and diode D3, ensures that the motor speed remains stable and responsive to adjustments made via R2.

The output of comparator U1 drives the MOSFET Q1 (MTP8P08), which acts as a switch to control the power supplied to the motor. The Zener diode D1 plays a critical role in protecting the gate of the MOSFET from voltage spikes, ensuring reliable operation. The design allows for precise control over the motor's operation, including starting, stopping, reversing, and oscillating, with the added feature of a variable delay that can be adjusted to suit specific operational requirements.

Overall, the design emphasizes high efficiency and simplicity, making it suitable for various applications in motor control systems where precise speed regulation and reliability are paramount.The use of power MOSFETs allows a direct interface between logic and motor power, which permits circuit simplicity as well as high efficiency. This speed control circuit can be packaged on a 22-pin, double-sided, 3.5 4-in. pc board. A 12 V control supply and a TRW BL11, 30 V motor are used; with minor changes other motor and control voltages can be accommodated.

For example, a single 24 V rail could supply both control and motor voltages. Motor and control voltages are kept separate here because CMOS logic is used to start, stop, reverse and oscillate the motor with a variable delay between motor reversals. Motor speed is established by potentiometer R2, which applies a corresponding dc voltage to the + input of comparator Ul, whose output is then applied to TMOS device MTP8P08 (Ql). Zener diode Dl limits the drive to Ql. The output of Ql drives the permanent magnet motor.Back emf is obtained from the motor via the network consisting of R8, R9, RIO, C2, C3 and D3; it is applied to—input of comparator Ul.

The circuit design leverages the advantages of power MOSFETs, allowing for efficient control of the motor's speed and direction. The incorporation of a 22-pin double-sided PCB enhances the circuit's compactness and facilitates efficient layout and routing. The choice of a 12 V control supply alongside a 30 V motor provides flexibility, allowing the circuit to be adapted for various applications with minimal alterations.

The speed control mechanism is centered around potentiometer R2, which functions as a variable resistor, enabling the user to adjust the voltage supplied to the positive input of comparator U1. Comparator U1 compares this voltage with the feedback voltage derived from the motor's back EMF. The feedback network, comprising resistors R8, R9, R10, capacitors C2 and C3, and diode D3, ensures that the motor speed remains stable and responsive to adjustments made via R2.

The output of comparator U1 drives the MOSFET Q1 (MTP8P08), which acts as a switch to control the power supplied to the motor. The Zener diode D1 plays a critical role in protecting the gate of the MOSFET from voltage spikes, ensuring reliable operation. The design allows for precise control over the motor's operation, including starting, stopping, reversing, and oscillating, with the added feature of a variable delay that can be adjusted to suit specific operational requirements.

Overall, the design emphasizes high efficiency and simplicity, making it suitable for various applications in motor control systems where precise speed regulation and reliability are paramount.The use of power MOSFETs allows a direct interface between logic and motor power, which permits circuit simplicity as well as high efficiency. This speed control circuit can be packaged on a 22-pin, double-sided, 3.5 4-in. pc board. A 12 V control supply and a TRW BL11, 30 V motor are used; with minor changes other motor and control voltages can be accommodated.

For example, a single 24 V rail could supply both control and motor voltages. Motor and control voltages are kept separate here because CMOS logic is used to start, stop, reverse and oscillate the motor with a variable delay between motor reversals. Motor speed is established by potentiometer R2, which applies a corresponding dc voltage to the + input of comparator Ul, whose output is then applied to TMOS device MTP8P08 (Ql). Zener diode Dl limits the drive to Ql. The output of Ql drives the permanent magnet motor.Back emf is obtained from the motor via the network consisting of R8, R9, RIO, C2, C3 and D3; it is applied to—input of comparator Ul.