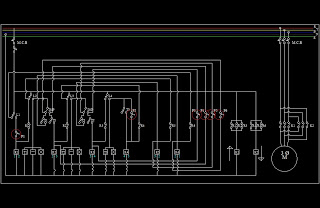

basic lift circuit four floors

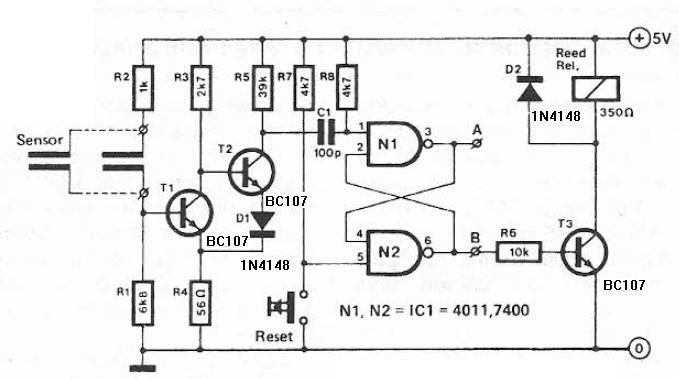

This is a basic lift circuit. When the P1 push button is pressed, the lift starts operating from the 1st floor to the 2nd floor. After a specified time duration, it automatically moves to the 3rd floor. The same sequence occurs when moving from the 3rd floor to the 4th floor.

The lift circuit operates using a series of interconnected components designed to facilitate vertical movement between floors in a building. The primary control element is the P1 push button, which initiates the lift's movement. Upon activation, a relay or motor driver circuit is engaged, powering the lift mechanism to ascend from the 1st floor to the 2nd floor.

The circuit may include a timer, which is crucial in determining the duration the lift remains at each floor. This timer can be implemented using a microcontroller or a simple RC timing circuit, depending on the complexity required. Once the timer elapses, a signal is sent to the lift control system, prompting it to engage the next relay or motor driver to continue the lift's journey to the 3rd floor.

Upon reaching the 3rd floor, the same process is repeated. The lift remains at this floor for a predetermined time before automatically moving to the 4th floor. This cycle of operation ensures that the lift is user-friendly and efficient, minimizing wait times for passengers.

Additional safety features may include limit switches that prevent the lift from exceeding its designated floors and emergency stop buttons that can be activated in case of malfunction. Power supply considerations must also be addressed, ensuring that the circuit can handle the load requirements of the lift motor while maintaining safety standards.

Overall, this basic lift circuit exemplifies a straightforward yet effective design for vertical transportation within a multi-story building.This is basic lift circuit. when press P1 push button lift starts to work 1st floor to 2 nd floor. Then after time duration it is automatically reach to 3 rd floor. And samething happen in 3rd floor & 4 th floor. 🔗 External reference

The lift circuit operates using a series of interconnected components designed to facilitate vertical movement between floors in a building. The primary control element is the P1 push button, which initiates the lift's movement. Upon activation, a relay or motor driver circuit is engaged, powering the lift mechanism to ascend from the 1st floor to the 2nd floor.

The circuit may include a timer, which is crucial in determining the duration the lift remains at each floor. This timer can be implemented using a microcontroller or a simple RC timing circuit, depending on the complexity required. Once the timer elapses, a signal is sent to the lift control system, prompting it to engage the next relay or motor driver to continue the lift's journey to the 3rd floor.

Upon reaching the 3rd floor, the same process is repeated. The lift remains at this floor for a predetermined time before automatically moving to the 4th floor. This cycle of operation ensures that the lift is user-friendly and efficient, minimizing wait times for passengers.

Additional safety features may include limit switches that prevent the lift from exceeding its designated floors and emergency stop buttons that can be activated in case of malfunction. Power supply considerations must also be addressed, ensuring that the circuit can handle the load requirements of the lift motor while maintaining safety standards.

Overall, this basic lift circuit exemplifies a straightforward yet effective design for vertical transportation within a multi-story building.This is basic lift circuit. when press P1 push button lift starts to work 1st floor to 2 nd floor. Then after time duration it is automatically reach to 3 rd floor. And samething happen in 3rd floor & 4 th floor. 🔗 External reference