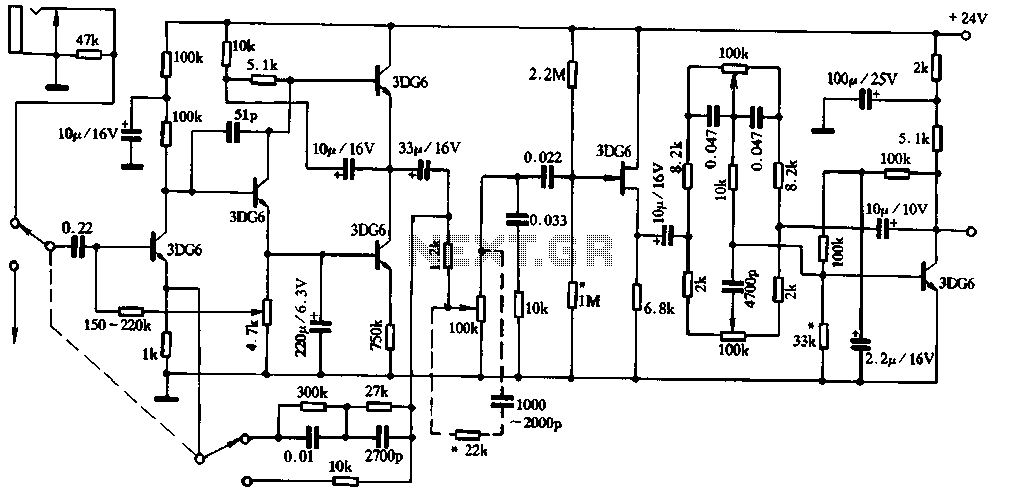

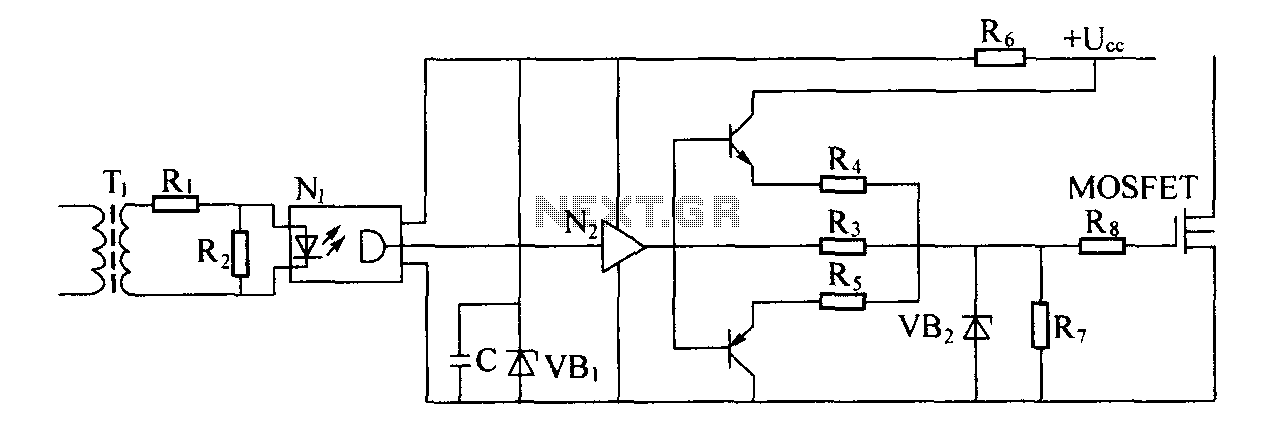

Battery Equality Monitor Circuit Schematic

Almost all 24V power systems in trucks, 4WDs, RVs, boats, etc., utilize two series-connected 12V lead-acid batteries. The charging system can only sustain the total voltage of the individual batteries. If one battery is failing, this circuit will illuminate an LED, thereby indicating potential battery issues. The circuit operates by detecting a voltage difference between the two series-connected 12V batteries. The idle current is sufficiently low to permit the unit to remain connected across the batteries continuously.

The described circuit functions as a voltage monitoring system for dual 12V lead-acid batteries configured in series to create a 24V power supply. This configuration is prevalent in various applications, including trucks, 4WD vehicles, recreational vehicles (RVs), and marine vessels. The primary goal of the circuit is to provide early detection of battery health issues by monitoring the voltage levels of each battery.

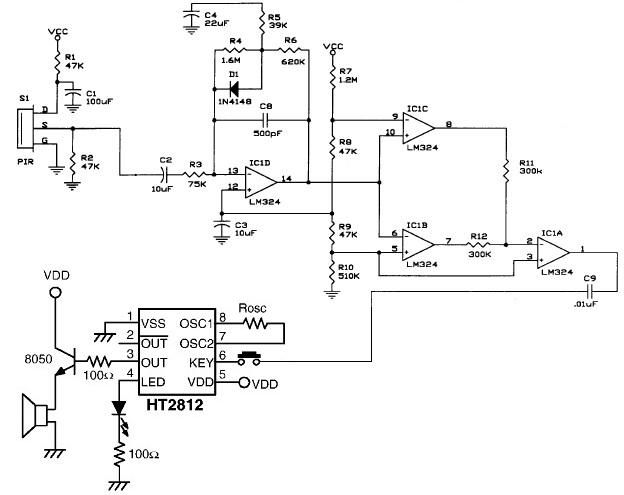

The circuit utilizes a microcontroller or a simple comparator circuit to measure the voltage across each battery. By comparing the voltages, the circuit can determine if one of the batteries is underperforming or failing. When a significant voltage difference is detected, indicating that one battery is not holding its charge as well as the other, an LED indicator is activated. This visual alert serves as a warning to the user, allowing for timely intervention before complete battery failure occurs.

In terms of design, the circuit should include necessary components such as resistors to limit current to the LED, a voltage divider to scale down the battery voltages to a manageable level for the comparator or microcontroller, and possibly a relay if further actions are required, such as disconnecting the failing battery from the circuit. Additionally, the idle current consumption of the circuit must be minimized, allowing it to remain connected across the batteries without draining them excessively.

Overall, this monitoring circuit enhances the reliability of 24V systems by providing critical feedback on battery health, thereby prolonging the lifespan of the batteries and ensuring the uninterrupted operation of connected systems.Almost all 24V power systems in trucks, 4WDs, RVs, boats, etc, employ two series-connected 12V lead-acid batteries. The charging system can only maintain the sum of the individual battery voltages. If one battery is failing, this circuit will light a LED. Hence impending battery problems can be forecast. The circuit works by detecting a voltage difference between the two series connected 12V batteries. Idle current is low enough to allow the unit to be permanently left across the batteries 🔗 External reference

The described circuit functions as a voltage monitoring system for dual 12V lead-acid batteries configured in series to create a 24V power supply. This configuration is prevalent in various applications, including trucks, 4WD vehicles, recreational vehicles (RVs), and marine vessels. The primary goal of the circuit is to provide early detection of battery health issues by monitoring the voltage levels of each battery.

The circuit utilizes a microcontroller or a simple comparator circuit to measure the voltage across each battery. By comparing the voltages, the circuit can determine if one of the batteries is underperforming or failing. When a significant voltage difference is detected, indicating that one battery is not holding its charge as well as the other, an LED indicator is activated. This visual alert serves as a warning to the user, allowing for timely intervention before complete battery failure occurs.

In terms of design, the circuit should include necessary components such as resistors to limit current to the LED, a voltage divider to scale down the battery voltages to a manageable level for the comparator or microcontroller, and possibly a relay if further actions are required, such as disconnecting the failing battery from the circuit. Additionally, the idle current consumption of the circuit must be minimized, allowing it to remain connected across the batteries without draining them excessively.

Overall, this monitoring circuit enhances the reliability of 24V systems by providing critical feedback on battery health, thereby prolonging the lifespan of the batteries and ensuring the uninterrupted operation of connected systems.Almost all 24V power systems in trucks, 4WDs, RVs, boats, etc, employ two series-connected 12V lead-acid batteries. The charging system can only maintain the sum of the individual battery voltages. If one battery is failing, this circuit will light a LED. Hence impending battery problems can be forecast. The circuit works by detecting a voltage difference between the two series connected 12V batteries. Idle current is low enough to allow the unit to be permanently left across the batteries 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713