Battery Powered Soldering Iron PCB

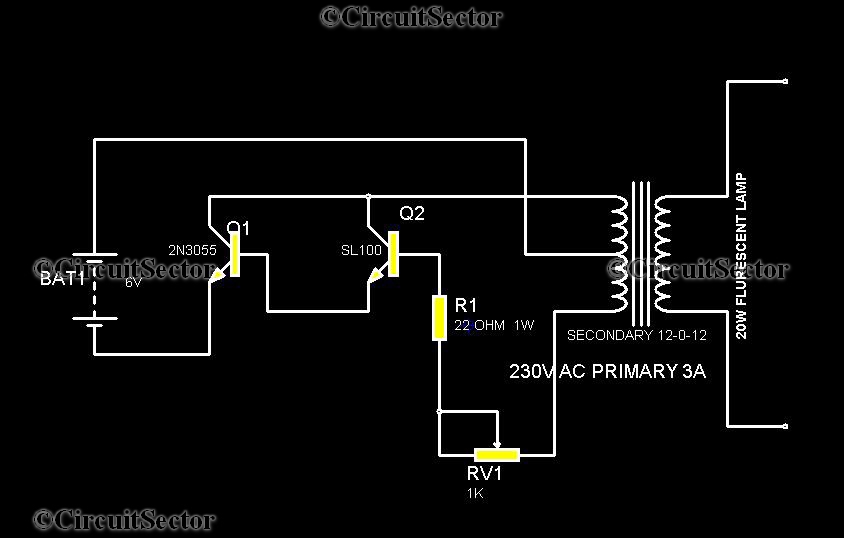

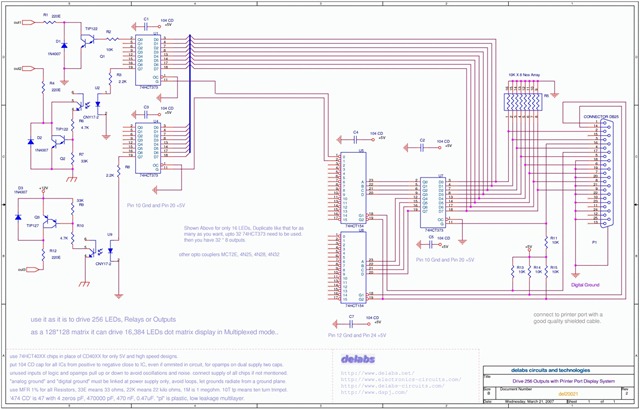

Traditional soldering irons utilize mains AC supply for heating, which can be inconvenient in the absence of such a power source. This document describes a simple and cost-effective inverter circuit designed for use with standard soldering irons (25W, 30W, 35W). The circuit allows for operation without mains power. It comprises eight transistors along with a few resistors and capacitors. A 12 Volt 7Ah battery is required for operation. Transistors T1 and T2, both BC547, form an astable multivibrator that generates a 50Hz signal. This output drives a PNP Darlington driver stage made up of transistors T3, T4, T5, and T6, which utilize BC558 and BD140. Two 2N3055 power transistors operate in a push-pull configuration, driving transformer X1, which in turn powers the soldering iron. Activating the circuit with switch S1 causes transformer X1 to produce 230V AC at its primary terminal, sufficient to heat the soldering iron. The duration of battery backup depends on the power rating of the soldering iron.

The inverter circuit designed for soldering iron applications addresses the limitations of conventional soldering methods that rely on mains electricity. The astable multivibrator configuration formed by the BC547 transistors (T1 and T2) is crucial for generating a consistent 50Hz square wave signal. This frequency is suitable for the operation of the transformer and the subsequent heating of the soldering iron.

The PNP Darlington stage, consisting of transistors T3 through T6, amplifies the signal from the astable multivibrator, ensuring that sufficient current is available to drive the power transistors. The choice of BC558 and BD140 in the Darlington configuration allows for high current gain, which is essential for efficient operation.

The push-pull arrangement of the 2N3055 transistors is particularly effective for driving the transformer X1. This configuration allows for efficient switching and minimizes power loss, making the circuit suitable for battery operation. The transformer is designed to step up the voltage to 230V AC, which is necessary for heating the soldering iron effectively.

The 12 Volt 7Ah battery provides the necessary power for the entire circuit. The selection of this battery capacity ensures a reasonable operating time, although the actual duration will vary based on the power rating of the soldering iron used. The circuit's design allows for portability and convenience, making it an excellent solution for fieldwork or situations where mains power is unavailable.

In summary, this inverter circuit provides a practical and efficient means of operating standard soldering irons away from mains electricity, utilizing a well-structured arrangement of transistors and passive components to achieve the desired outcome.As we know, traditional soldering irons uses mains ac supply to get heated but this will be annoying when we want to use it in the absence of mains supply. Here is a simple inexpensive circuit which we can call it as a inverter for normal soldering iron (25W, 30W, 35W).

The circuit can drive the soldering iron in the absence of power supply from m ains. This cold soldering iron circuit uses eight transistors and few resistors and capacitors. The battery should be a 12 Volt 7Ah. Each BC547 transitors - T1 and T2 form an astable multivibrator that produces 50Hz signal. The output of it drives the pnp darlington driver stage transistors formed by transistors T3-T5 and T6 utilizing BC558 and BD140. Two 2N3055 power transistors will perform push-pull operation whose output drives the transformer X1 which drives the soldering iron.

When you power the circuit using switch S1, transformer X1 produces 230V AC at its primary terminal. This voltage can be used to heat your soldering iron. The battery backup will depend upon the power rating of the iron. 🔗 External reference

The inverter circuit designed for soldering iron applications addresses the limitations of conventional soldering methods that rely on mains electricity. The astable multivibrator configuration formed by the BC547 transistors (T1 and T2) is crucial for generating a consistent 50Hz square wave signal. This frequency is suitable for the operation of the transformer and the subsequent heating of the soldering iron.

The PNP Darlington stage, consisting of transistors T3 through T6, amplifies the signal from the astable multivibrator, ensuring that sufficient current is available to drive the power transistors. The choice of BC558 and BD140 in the Darlington configuration allows for high current gain, which is essential for efficient operation.

The push-pull arrangement of the 2N3055 transistors is particularly effective for driving the transformer X1. This configuration allows for efficient switching and minimizes power loss, making the circuit suitable for battery operation. The transformer is designed to step up the voltage to 230V AC, which is necessary for heating the soldering iron effectively.

The 12 Volt 7Ah battery provides the necessary power for the entire circuit. The selection of this battery capacity ensures a reasonable operating time, although the actual duration will vary based on the power rating of the soldering iron used. The circuit's design allows for portability and convenience, making it an excellent solution for fieldwork or situations where mains power is unavailable.

In summary, this inverter circuit provides a practical and efficient means of operating standard soldering irons away from mains electricity, utilizing a well-structured arrangement of transistors and passive components to achieve the desired outcome.As we know, traditional soldering irons uses mains ac supply to get heated but this will be annoying when we want to use it in the absence of mains supply. Here is a simple inexpensive circuit which we can call it as a inverter for normal soldering iron (25W, 30W, 35W).

The circuit can drive the soldering iron in the absence of power supply from m ains. This cold soldering iron circuit uses eight transistors and few resistors and capacitors. The battery should be a 12 Volt 7Ah. Each BC547 transitors - T1 and T2 form an astable multivibrator that produces 50Hz signal. The output of it drives the pnp darlington driver stage transistors formed by transistors T3-T5 and T6 utilizing BC558 and BD140. Two 2N3055 power transistors will perform push-pull operation whose output drives the transformer X1 which drives the soldering iron.

When you power the circuit using switch S1, transformer X1 produces 230V AC at its primary terminal. This voltage can be used to heat your soldering iron. The battery backup will depend upon the power rating of the iron. 🔗 External reference