Car Analog tachometer circuit

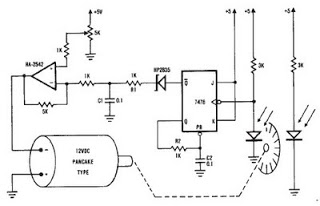

This is a nice design for people who have no tachometer in the car or on the bike. The circuit uses two ICs: an NE 555 and a CA 3140. The input of the circuit is connected to the breaker of the motor (on the side that is not connected to ground). Thus, the ignition pulses are fed into the circuit. By the two ICs, this signal is transformed into a speed-dependent voltage which is then fed to the meter. The scale of the meter is 0 to 10,000 rpm. The circuit must be adjusted. For this, R6 of IC2 is temporarily disconnected. A voltage of 4 V is then applied to R6. P2 is adjusted so that the meter shows full scale deflection. After this adjustment, R6 is reconnected. A voltage with a known frequency (for example, from a transformer at 220 V) is applied. The speed to which the meter is set can be calculated using the formula: rpm = (30 * f * t) / n. Here, rpm is the number of revolutions per minute, f is the frequency of the alternating voltage, t is the number of motor cycles (e.g., 4-stroke), and n is the number of cylinders. This adjustment is done using P1. It is important to remember that the full scale is 10,000 rpm.

R1 = 1 kOhm

R2 = 1 MΩ

R3, R5 = 10 kOhm

R4 = 6.8 kOhm

R6 = see chart

P1 = 5 kOhm

P2 = see chart

C1, C2 = 100 nF

C3 = 220 nF

C4 = 47 µF

D1, D2 = 1N 4001

D3 = 4.7 V zener

IC1 = NE 555

IC2 = CA 3140

M1 = 100 µA meter, or 1 mA

The circuit operates by detecting the ignition pulses generated by the motor's breaker, which produces a rectangular waveform corresponding to the engine's firing frequency. The NE 555 timer (IC1) is configured in monostable mode, allowing it to react to each pulse and generate a corresponding output signal. This output signal is then processed by the CA 3140 operational amplifier (IC2), which converts the pulse frequency into a proportional voltage that drives the analog meter (M1).

The adjustable resistors P1 and P2 allow for calibration of the circuit to ensure accurate readings on the meter. P1 is used to set the characteristics of the output voltage based on the input frequency, while P2 is used to calibrate the meter to read full scale at 10,000 rpm. The use of capacitors (C1, C2, C3, and C4) in the circuit helps stabilize the voltage levels and filter out noise, ensuring a clean signal is delivered to the meter.

The diodes (D1, D2, and D3) serve protection and voltage regulation roles within the circuit. D1 and D2 are standard rectifier diodes that protect the circuit from reverse polarity, while D3, a zener diode, regulates voltage levels to prevent damage to sensitive components.

The circuit's design is suitable for installation in vehicles lacking a built-in tachometer, providing a reliable method to monitor engine speed. Proper installation and calibration are essential for achieving accurate readings, and the circuit can be adjusted to accommodate different engine types and configurations.This is a nice design for people who have no tachometer in the car or on the bike have. The circuit uses two ICs: an NE 555 and a CA 3140. The input of the circuit to the breaker of the motor (on the side that is not connected to ground). Thus, the ignition pulses within the circuit. By the two IC's, this signal then transformed into a speed-dependent voltage which is fed to the meter. The scale of the meter is 0 to 10 000 rpm. The circuit must be adjusted. For this, R6 IC2 temporarily disconnected. On R6 is a voltage of 4 V put. P2 is then adjusted so that the meter full scale deflection. Then again put R6. Then in mass and a voltage is alternating or block whose frequency is known (eg a transformer at 220 V). The speed to which the meter is set to be calculated using the formula: rpm = (30 * f * t) / n. This is the number of revolutions per minute rpm, f is the frequency of the alternating voltage, t is the number of motor cycles (eg 4-stroke) and n the number of cylinders.

This adjustment happens to P1. Remember always that the full scale is 10 000 rpm. R1 = 1 kOhm R2 = 1 M ½ R3, R5 = 10 kOhm R4 = 6.8 kOhm R6 = see chart P1 = 5 kOhm P2 = see chart C1, C2 = 100 nF C3 = 220 nF C4 = 47 uF D1, D2 = 1N 4001 D3 = 4.7 V zener IC1 = NE 555 IC2 = CA 3140 M1 = 100 uA meter, or 1 mA 🔗 External reference

R1 = 1 kOhm

R2 = 1 MΩ

R3, R5 = 10 kOhm

R4 = 6.8 kOhm

R6 = see chart

P1 = 5 kOhm

P2 = see chart

C1, C2 = 100 nF

C3 = 220 nF

C4 = 47 µF

D1, D2 = 1N 4001

D3 = 4.7 V zener

IC1 = NE 555

IC2 = CA 3140

M1 = 100 µA meter, or 1 mA

The circuit operates by detecting the ignition pulses generated by the motor's breaker, which produces a rectangular waveform corresponding to the engine's firing frequency. The NE 555 timer (IC1) is configured in monostable mode, allowing it to react to each pulse and generate a corresponding output signal. This output signal is then processed by the CA 3140 operational amplifier (IC2), which converts the pulse frequency into a proportional voltage that drives the analog meter (M1).

The adjustable resistors P1 and P2 allow for calibration of the circuit to ensure accurate readings on the meter. P1 is used to set the characteristics of the output voltage based on the input frequency, while P2 is used to calibrate the meter to read full scale at 10,000 rpm. The use of capacitors (C1, C2, C3, and C4) in the circuit helps stabilize the voltage levels and filter out noise, ensuring a clean signal is delivered to the meter.

The diodes (D1, D2, and D3) serve protection and voltage regulation roles within the circuit. D1 and D2 are standard rectifier diodes that protect the circuit from reverse polarity, while D3, a zener diode, regulates voltage levels to prevent damage to sensitive components.

The circuit's design is suitable for installation in vehicles lacking a built-in tachometer, providing a reliable method to monitor engine speed. Proper installation and calibration are essential for achieving accurate readings, and the circuit can be adjusted to accommodate different engine types and configurations.This is a nice design for people who have no tachometer in the car or on the bike have. The circuit uses two ICs: an NE 555 and a CA 3140. The input of the circuit to the breaker of the motor (on the side that is not connected to ground). Thus, the ignition pulses within the circuit. By the two IC's, this signal then transformed into a speed-dependent voltage which is fed to the meter. The scale of the meter is 0 to 10 000 rpm. The circuit must be adjusted. For this, R6 IC2 temporarily disconnected. On R6 is a voltage of 4 V put. P2 is then adjusted so that the meter full scale deflection. Then again put R6. Then in mass and a voltage is alternating or block whose frequency is known (eg a transformer at 220 V). The speed to which the meter is set to be calculated using the formula: rpm = (30 * f * t) / n. This is the number of revolutions per minute rpm, f is the frequency of the alternating voltage, t is the number of motor cycles (eg 4-stroke) and n the number of cylinders.

This adjustment happens to P1. Remember always that the full scale is 10 000 rpm. R1 = 1 kOhm R2 = 1 M ½ R3, R5 = 10 kOhm R4 = 6.8 kOhm R6 = see chart P1 = 5 kOhm P2 = see chart C1, C2 = 100 nF C3 = 220 nF C4 = 47 uF D1, D2 = 1N 4001 D3 = 4.7 V zener IC1 = NE 555 IC2 = CA 3140 M1 = 100 uA meter, or 1 mA 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713