Car Parking Sensor Circuit Schematic Free With Explanation

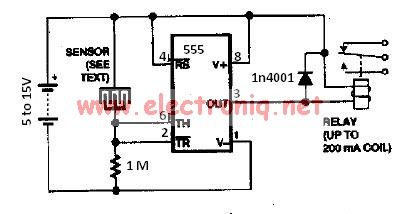

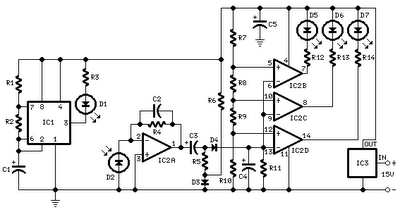

This circuit was designed to assist in parking a car near a garage wall while reversing. LED D7 lights up when the distance to the wall is approximately 20 cm. When the distance reduces to about 10 cm, both D7 and D6 illuminate, and at approximately 6 cm, D7, D6, and D5 all light up. This provides alerts as the vehicle approaches too close to the wall. The distances mentioned may vary based on the infrared transmitting and receiving LEDs used, which are significantly affected by the color of the reflecting surface. Dark surfaces can greatly reduce the sensitivity of the device. This circuit can also be utilized in other applications, such as liquid level detection and proximity sensing. IC1 operates as an oscillator, driving the infrared LED with 0.8 ms pulses at a frequency of 120 Hz and a peak current of about 300 mA. D1 and D2 are positioned facing the car, a few centimeters apart, on a small breadboard strip attached to the wall. D2 receives the infrared beam emitted by D1 and reflected by the surface in front of it. The signal is amplified by IC2A and peak detected by D4 and C4. Diode D3, along with resistors R5 and R6, compensates for the forward voltage drop of D4. A DC voltage that corresponds to the distance of the reflecting object is fed into the inverting inputs of three voltage comparators. These comparators turn the LEDs on and off based on voltages at their non-inverting inputs, which are determined by a voltage divider resistor chain composed of R7 to R10.

The circuit operates by utilizing infrared light to detect the proximity of objects, specifically the wall of a garage when parking. The core of the system is an oscillator circuit formed by IC1, which generates a series of pulses that drive the infrared LED (D1). The emitted infrared light travels towards the wall and is reflected back to the receiving LED (D2). The distance to the wall can be gauged by measuring the time it takes for the light to return, although in this design, the reflected light's intensity is directly correlated with the distance.

The reflected signal from D2 is then amplified by IC2A to ensure that it is strong enough for further processing. The peak detection stage, which includes D4 and C4, converts the varying signal into a stable DC voltage that represents the distance to the reflecting surface. The voltage levels are then compared against predefined thresholds set by a resistor divider network (R7-R10), which establishes the reference voltages for the voltage comparators.

As the vehicle approaches the wall, the increasing intensity of the reflected infrared light results in a corresponding increase in the DC voltage output. When this voltage surpasses the thresholds set by the comparators, the LEDs (D5, D6, D7) are activated in a sequential manner, providing a visual indication of how close the vehicle is to the wall. This visual feedback enhances the driver's awareness, helping to prevent collisions with the wall during parking maneuvers.

The design can be adapted for various applications beyond parking assistance, such as in liquid level sensing where the distance to the liquid surface can be measured, or in other proximity detection systems. Adjustments in the choice of infrared LEDs and the configuration of the circuit can optimize performance for different reflecting surfaces and environmental conditions.This circuit was designed as an aid in parking the car near the garage wall when backing up. LED D7 illuminates when bumper-wall distance is about 20 cm. , D7+D6 illuminate at about 10 cm. and D7+D6+D5 at about 6 cm. In this manner you are alerted when approaching too close to the wall. All distances mentioned before can vary, depending on infra-re d transmitting and receiving LEDs used and are mostly affected by the color of the reflecting surface. Black surfaces lower greatly the device sensitivity. Obviously, you can use this circuit in other applications like liquids level detection, proximity devices etc.

IC1 forms an oscillator driving the infra-red LED by means of 0. 8mSec. pulses at 120Hz frequency and about 300mA peak current. D1 & D2 are placed facing the car on the same line, a couple of centimeters apart, on a short breadboard strip fastened to the wall. D2 picks-up the infra-red beam generated by D1 and reflected by the surface placed in front of it. The signal is amplified by IC2A and peak detected by D4 & C4. Diode D3, with R5 & R6, compensates for the forward diode drop of D4. A DC voltage proportional to the distance of the reflecting object and D1 & D2 feeds the inverting inputs of three voltage comparators.

These comparators switch on and off the LEDs, referring to voltages at their non-inverting inputs set by the voltage divider resistor chain R7-R10. 🔗 External reference

The circuit operates by utilizing infrared light to detect the proximity of objects, specifically the wall of a garage when parking. The core of the system is an oscillator circuit formed by IC1, which generates a series of pulses that drive the infrared LED (D1). The emitted infrared light travels towards the wall and is reflected back to the receiving LED (D2). The distance to the wall can be gauged by measuring the time it takes for the light to return, although in this design, the reflected light's intensity is directly correlated with the distance.

The reflected signal from D2 is then amplified by IC2A to ensure that it is strong enough for further processing. The peak detection stage, which includes D4 and C4, converts the varying signal into a stable DC voltage that represents the distance to the reflecting surface. The voltage levels are then compared against predefined thresholds set by a resistor divider network (R7-R10), which establishes the reference voltages for the voltage comparators.

As the vehicle approaches the wall, the increasing intensity of the reflected infrared light results in a corresponding increase in the DC voltage output. When this voltage surpasses the thresholds set by the comparators, the LEDs (D5, D6, D7) are activated in a sequential manner, providing a visual indication of how close the vehicle is to the wall. This visual feedback enhances the driver's awareness, helping to prevent collisions with the wall during parking maneuvers.

The design can be adapted for various applications beyond parking assistance, such as in liquid level sensing where the distance to the liquid surface can be measured, or in other proximity detection systems. Adjustments in the choice of infrared LEDs and the configuration of the circuit can optimize performance for different reflecting surfaces and environmental conditions.This circuit was designed as an aid in parking the car near the garage wall when backing up. LED D7 illuminates when bumper-wall distance is about 20 cm. , D7+D6 illuminate at about 10 cm. and D7+D6+D5 at about 6 cm. In this manner you are alerted when approaching too close to the wall. All distances mentioned before can vary, depending on infra-re d transmitting and receiving LEDs used and are mostly affected by the color of the reflecting surface. Black surfaces lower greatly the device sensitivity. Obviously, you can use this circuit in other applications like liquids level detection, proximity devices etc.

IC1 forms an oscillator driving the infra-red LED by means of 0. 8mSec. pulses at 120Hz frequency and about 300mA peak current. D1 & D2 are placed facing the car on the same line, a couple of centimeters apart, on a short breadboard strip fastened to the wall. D2 picks-up the infra-red beam generated by D1 and reflected by the surface placed in front of it. The signal is amplified by IC2A and peak detected by D4 & C4. Diode D3, with R5 & R6, compensates for the forward diode drop of D4. A DC voltage proportional to the distance of the reflecting object and D1 & D2 feeds the inverting inputs of three voltage comparators.

These comparators switch on and off the LEDs, referring to voltages at their non-inverting inputs set by the voltage divider resistor chain R7-R10. 🔗 External reference