Constant Speed PWM Motor Control

A constant speed motor control can be achieved using closed-loop (servo) control. A constant speed motor maintains a steady speed regardless of variations in load.

In a closed-loop control system, feedback is utilized to compare the actual speed of the motor with the desired speed, allowing for adjustments to be made in real-time. This is typically accomplished through the use of sensors that monitor the motor's speed and provide this information to a controller, which processes the data and adjusts the input to the motor accordingly.

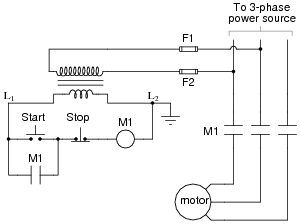

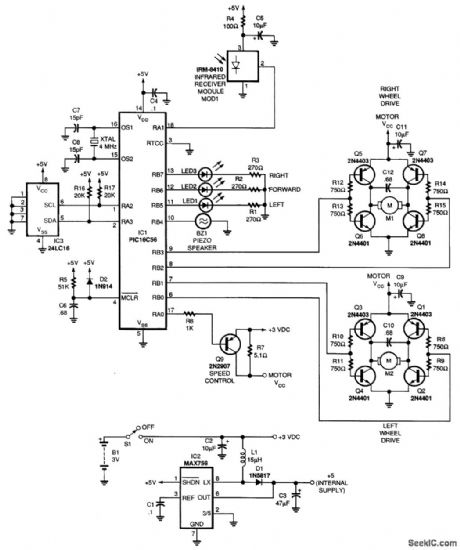

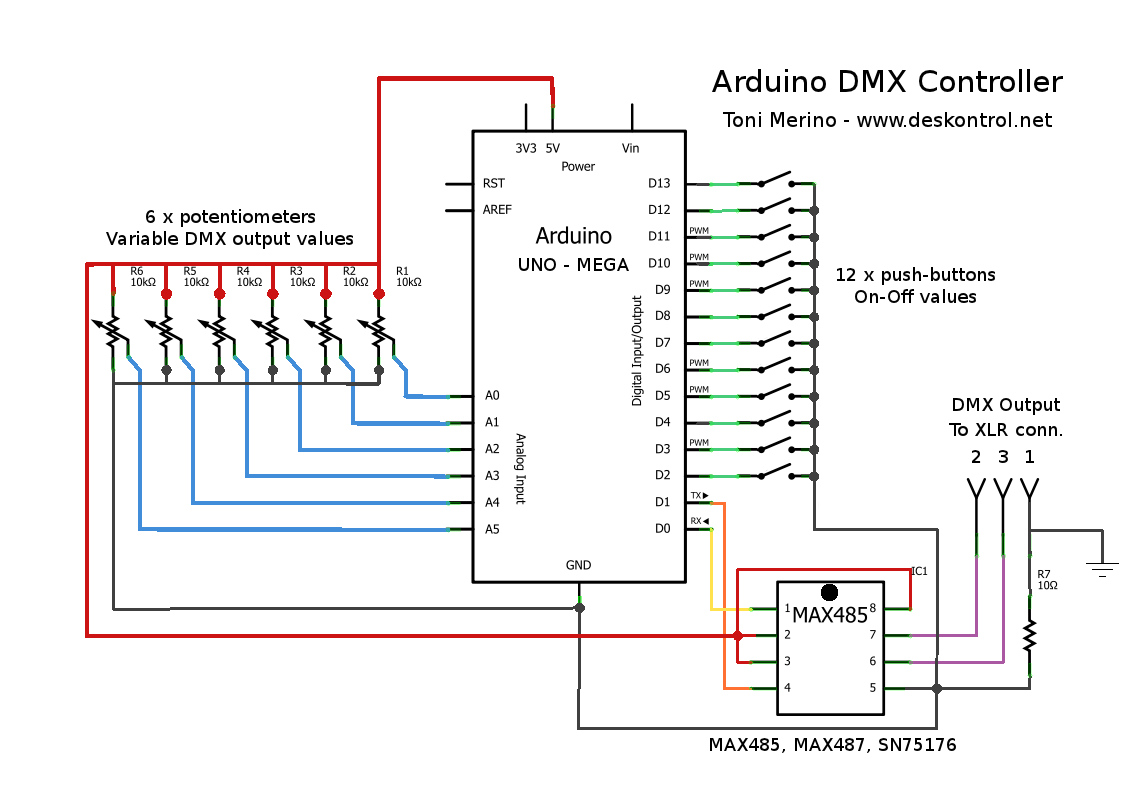

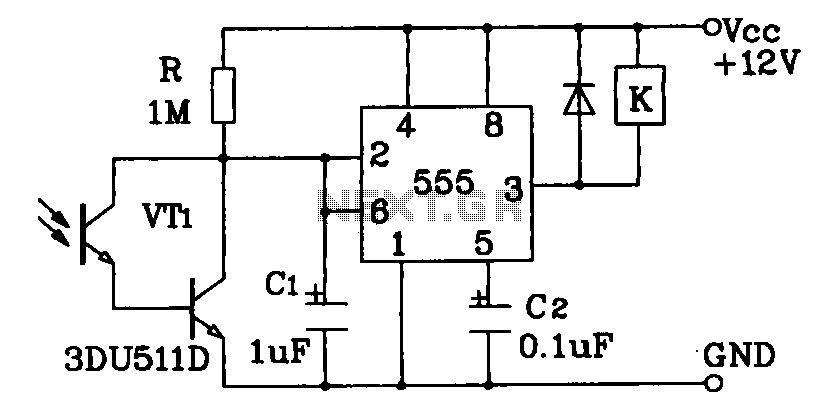

The essential components of a closed-loop motor control system include a motor, a speed sensor (such as an encoder or tachometer), a controller (often a microcontroller or a dedicated motor control IC), and a power driver circuit. The speed sensor measures the actual speed of the motor and sends this data to the controller. The controller calculates the difference between the desired speed and the actual speed, known as the error signal. Based on this error, the controller adjusts the duty cycle of the PWM signal sent to the power driver, which in turn controls the voltage and current supplied to the motor.

In designing the schematic for a closed-loop motor control system, it is crucial to select an appropriate motor type (e.g., DC, stepper, or brushless) based on the application requirements. The power driver circuit must be capable of handling the motor's current and voltage specifications. Additionally, the choice of feedback sensor impacts the overall accuracy and responsiveness of the control system.

The controller may implement various control algorithms, such as proportional-integral-derivative (PID) control, to optimize performance. The tuning of PID parameters is vital for achieving the desired response characteristics, including stability, speed of response, and minimal steady-state error.

Overall, a closed-loop constant speed motor control system is integral in applications requiring precise speed regulation, such as robotics, conveyor systems, and automated machinery. Proper design and implementation of the control circuitry ensure that the motor operates efficiently and reliably under varying load conditions.To make a constant speed motor control we can use Closed loop (servo) control. Constant speed motor is a motor that has constant speed although the load is.. 🔗 External reference

In a closed-loop control system, feedback is utilized to compare the actual speed of the motor with the desired speed, allowing for adjustments to be made in real-time. This is typically accomplished through the use of sensors that monitor the motor's speed and provide this information to a controller, which processes the data and adjusts the input to the motor accordingly.

The essential components of a closed-loop motor control system include a motor, a speed sensor (such as an encoder or tachometer), a controller (often a microcontroller or a dedicated motor control IC), and a power driver circuit. The speed sensor measures the actual speed of the motor and sends this data to the controller. The controller calculates the difference between the desired speed and the actual speed, known as the error signal. Based on this error, the controller adjusts the duty cycle of the PWM signal sent to the power driver, which in turn controls the voltage and current supplied to the motor.

In designing the schematic for a closed-loop motor control system, it is crucial to select an appropriate motor type (e.g., DC, stepper, or brushless) based on the application requirements. The power driver circuit must be capable of handling the motor's current and voltage specifications. Additionally, the choice of feedback sensor impacts the overall accuracy and responsiveness of the control system.

The controller may implement various control algorithms, such as proportional-integral-derivative (PID) control, to optimize performance. The tuning of PID parameters is vital for achieving the desired response characteristics, including stability, speed of response, and minimal steady-state error.

Overall, a closed-loop constant speed motor control system is integral in applications requiring precise speed regulation, such as robotics, conveyor systems, and automated machinery. Proper design and implementation of the control circuitry ensure that the motor operates efficiently and reliably under varying load conditions.To make a constant speed motor control we can use Closed loop (servo) control. Constant speed motor is a motor that has constant speed although the load is.. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713