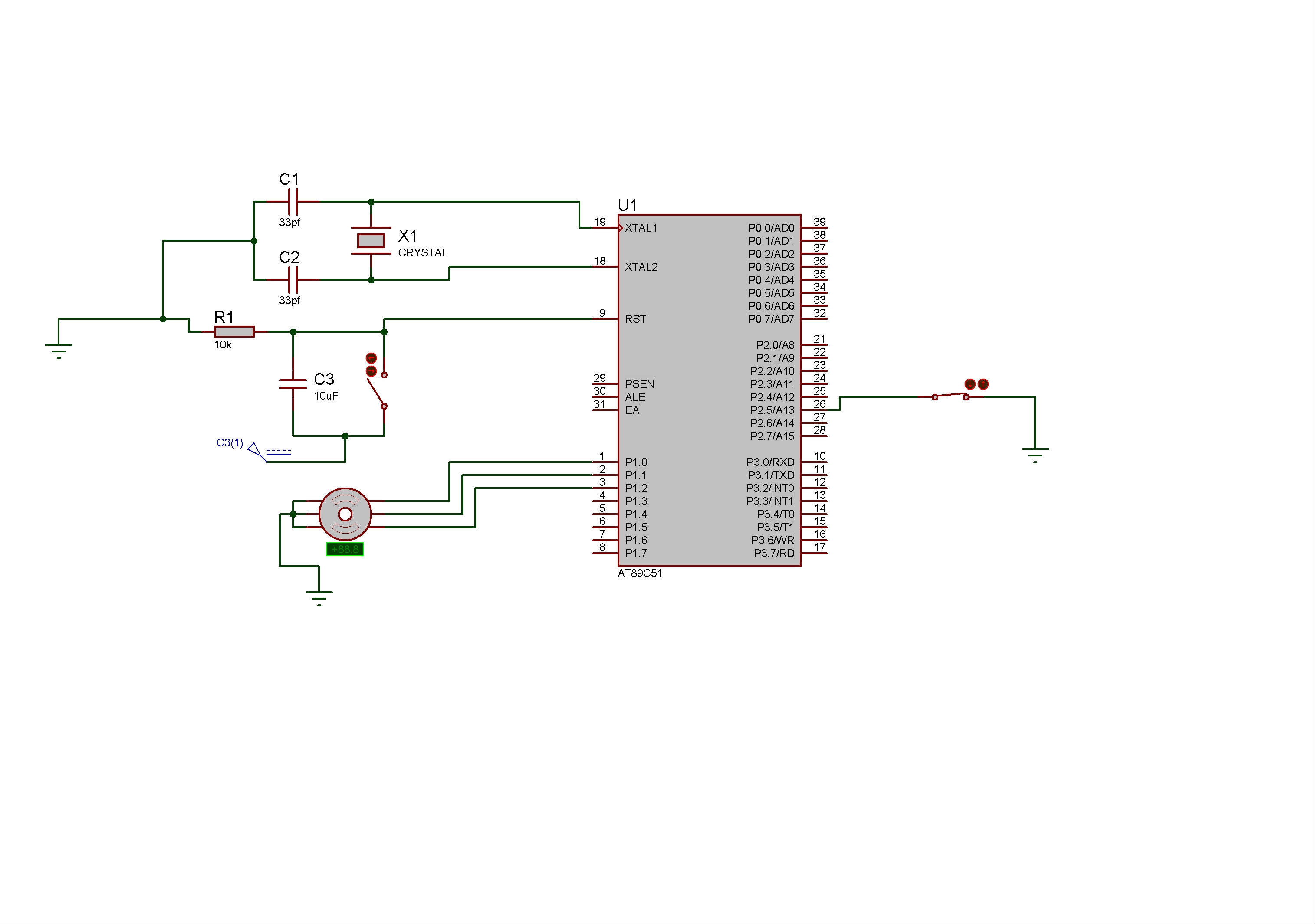

Controlling of Stepper Motor rotation in both direction using 8051 Microcontroller

Stepper motors consist of a permanent magnet rotating shaft, known as the rotor, and electromagnets on the stationary part that surrounds the motor, referred to as the stator. One complete rotation of a stepper motor is illustrated. At position 1, the rotor begins at the upper electromagnet, which is currently active and has voltage applied.

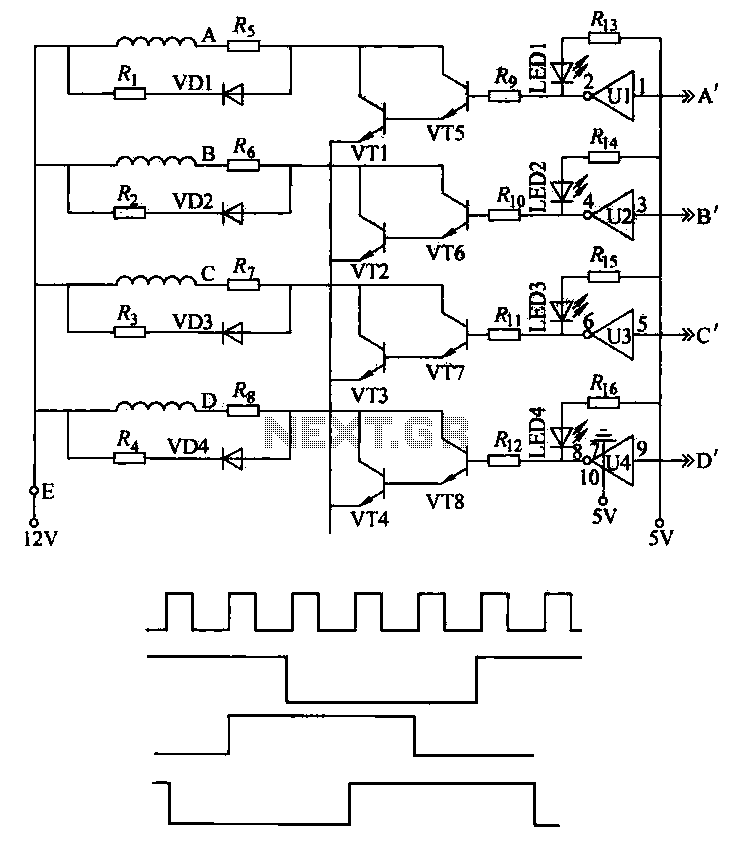

Stepper motors operate based on the principle of electromagnetic induction. The rotor, which is a permanent magnet, aligns itself with the magnetic field generated by the stator's electromagnets. The stator typically consists of multiple coils arranged in a specific sequence. When voltage is applied to these coils in a precise order, the magnetic field produced causes the rotor to step from one position to another, allowing for controlled movement.

The stepper motor's movement is characterized by discrete steps, which are defined by the number of poles in the rotor and the arrangement of the stator coils. The total number of steps per revolution can vary, with common configurations offering 200 steps per revolution (1.8 degrees per step) or 400 steps per revolution (0.9 degrees per step). This capability enables stepper motors to achieve high precision in positioning applications.

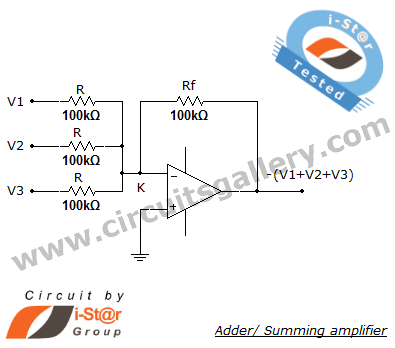

Control of a stepper motor is typically achieved through a driver circuit that sequences the voltage applied to the stator coils. The driver can be controlled using various methods, such as full-step, half-step, or microstepping techniques. Full-step operation energizes two coils at a time, while half-stepping alternates between energizing one and two coils, effectively doubling the resolution. Microstepping further divides each step into smaller increments, allowing for smoother motion and finer control.

In practical applications, stepper motors are widely used in robotics, CNC machinery, and 3D printers due to their ability to provide precise control of position and speed without the need for feedback systems. The simplicity of their control mechanisms and their robustness in various environments make them a popular choice for applications requiring accurate and repeatable motion.Stepper motors consist of a permanent magnet rotating shaft, called the rotor, and electromagnets on the stationary portion that surrounds the motor, called the stator. illustrates one complete rotation of a stepper motor. At position 1, we can see that the rotor is beginning at the upper electromagnet, which is currently active (has voltage applied.

🔗 External reference

Stepper motors operate based on the principle of electromagnetic induction. The rotor, which is a permanent magnet, aligns itself with the magnetic field generated by the stator's electromagnets. The stator typically consists of multiple coils arranged in a specific sequence. When voltage is applied to these coils in a precise order, the magnetic field produced causes the rotor to step from one position to another, allowing for controlled movement.

The stepper motor's movement is characterized by discrete steps, which are defined by the number of poles in the rotor and the arrangement of the stator coils. The total number of steps per revolution can vary, with common configurations offering 200 steps per revolution (1.8 degrees per step) or 400 steps per revolution (0.9 degrees per step). This capability enables stepper motors to achieve high precision in positioning applications.

Control of a stepper motor is typically achieved through a driver circuit that sequences the voltage applied to the stator coils. The driver can be controlled using various methods, such as full-step, half-step, or microstepping techniques. Full-step operation energizes two coils at a time, while half-stepping alternates between energizing one and two coils, effectively doubling the resolution. Microstepping further divides each step into smaller increments, allowing for smoother motion and finer control.

In practical applications, stepper motors are widely used in robotics, CNC machinery, and 3D printers due to their ability to provide precise control of position and speed without the need for feedback systems. The simplicity of their control mechanisms and their robustness in various environments make them a popular choice for applications requiring accurate and repeatable motion.Stepper motors consist of a permanent magnet rotating shaft, called the rotor, and electromagnets on the stationary portion that surrounds the motor, called the stator. illustrates one complete rotation of a stepper motor. At position 1, we can see that the rotor is beginning at the upper electromagnet, which is currently active (has voltage applied.

🔗 External reference