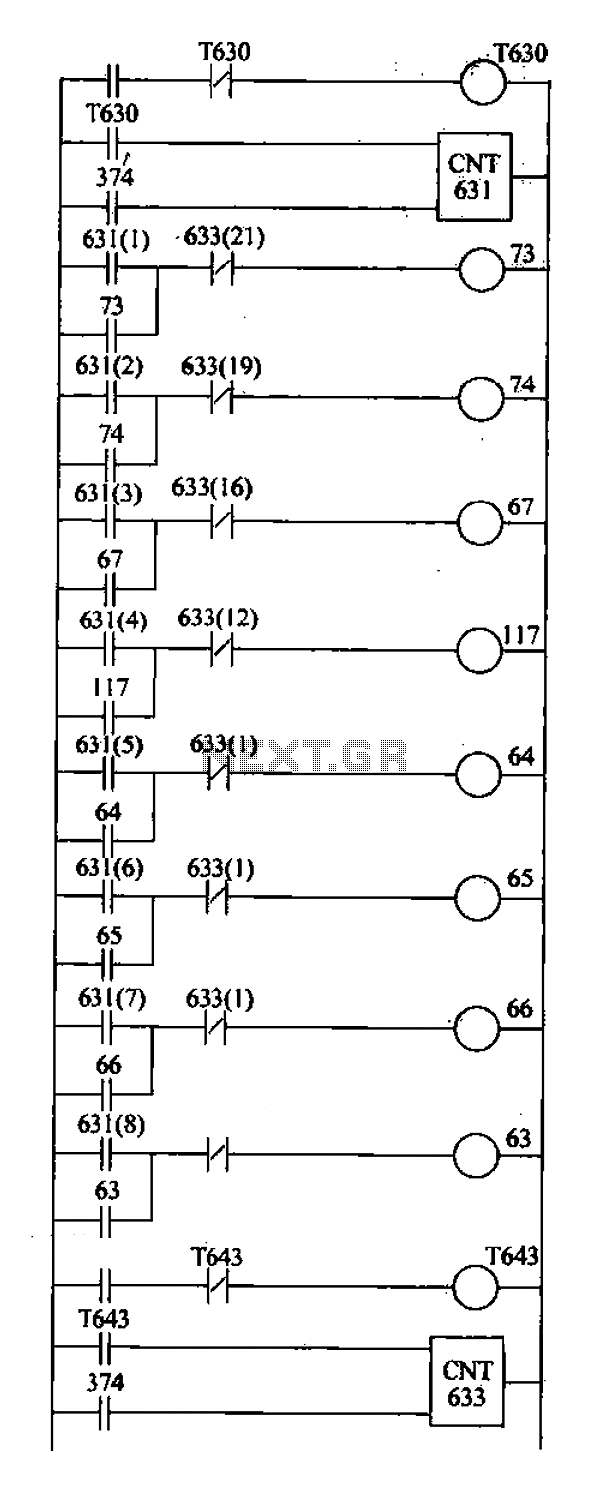

Conveyor control Ladder

Based on the system characteristics, a drum controller is utilized to meet the specified requirements, with the design of the ladder as illustrated in the accompanying figure. 1) C631 and C633 function as a drum controller, counting pulses generated by T630, with a pulse period of 5 seconds. C633 is employed for counting pulses generated by T643, also with a 5-second pulse period. 2) When the start signal is activated, T630 generates a pulse every 5 seconds, advancing C631, which causes the corresponding normally open contacts to close, initiating the equipment in sequence. 3) Upon activation of the stop signal, T633 generates a pulse every 5 seconds, advancing C633, and when the appropriate time is reached, the corresponding normally closed contacts close, commanding the equipment to stop. 4) In conclusion, this design exemplifies the automatic control of a sand production line, where timer, drum controller, and shift register sequence control ladder designs are employed according to the flow characteristics of the sand transport and grinding roller conveyor system. It is evident that the PLC offers robust control capabilities, with a wealth of programming instructions, allowing for flexible and convenient user program design, making it highly suitable for the automation and control of production line delivery systems.

The described circuit employs a drum controller for sequential control of equipment in a sand production line, utilizing pulse counting mechanisms to manage operational states effectively. The primary components include timers T630 and T643, which generate pulses at regular intervals, specifically every 5 seconds. The drum controller, comprising capacitors C631 and C633, counts these pulses to determine the operational sequence of the equipment.

In the operational phase, when the start signal is received, T630 initiates pulse generation. Each pulse advances the drum controller (C631), causing the associated normally open contacts to close, which starts the machinery in a predetermined sequence. This ensures that each piece of equipment is activated in the correct order, optimizing the production flow and preventing operational overlaps that could lead to inefficiencies or equipment damage.

Conversely, when a stop signal is activated, T633 takes over to control the stopping sequence. It generates pulses in a similar manner, advancing C633. Upon reaching a specified count, the drum controller closes the normally closed contacts, which halts the operation of the equipment. This method of control allows for precise timing and coordination among the different components of the production line, ensuring safety and efficiency.

The integration of a programmable logic controller (PLC) within this design enhances the system's flexibility and adaptability. The PLC can be programmed with various instructions tailored to specific operational needs, allowing for adjustments in the timing, sequence, and conditions under which equipment operates. This capability is particularly beneficial in environments where production requirements may change frequently, providing a dynamic solution to automation challenges.

Overall, the schematic design exemplifies a robust approach to automation in material handling and production processes, demonstrating the effectiveness of using a drum controller in conjunction with PLC technology for real-time operational management.According to the characteristics of the system, using the drum controller to achieve the above requirements, the design of the ladder as shown in FIG. As follows: 1) C631, C633 as a drum controller, which counts pulses generated by the T630, the pulse period is sequentially stopped at 5s C633. Use, its counting pulses generated by the T643, the pulse period is 5s. 2) after the start signal is active. T630 produces a pulse every 5s, C631 step, the corresponding pair of normally open contacts closed, the equipment along the sequence start.

3) After the stop signal is active, T633 produces a pulse every 5s, C633 step, and when it reaches the appropriate time, a corresponding pair of normally closed contacts closed, the equipment order to stop. (4) Conclusion In this case sand production line automatic control, for example, according to transport sand, sand and grind roller conveyor system flow characteristics, were used for the timer, drum controller, a shift register sequence control ladder the design of.

As can be seen, PLC in order to control side surfaces powerful, has a wealth of programming instructions, user program design flexible, convenient and very suitable delivery systems such as automation and control production lines.

The described circuit employs a drum controller for sequential control of equipment in a sand production line, utilizing pulse counting mechanisms to manage operational states effectively. The primary components include timers T630 and T643, which generate pulses at regular intervals, specifically every 5 seconds. The drum controller, comprising capacitors C631 and C633, counts these pulses to determine the operational sequence of the equipment.

In the operational phase, when the start signal is received, T630 initiates pulse generation. Each pulse advances the drum controller (C631), causing the associated normally open contacts to close, which starts the machinery in a predetermined sequence. This ensures that each piece of equipment is activated in the correct order, optimizing the production flow and preventing operational overlaps that could lead to inefficiencies or equipment damage.

Conversely, when a stop signal is activated, T633 takes over to control the stopping sequence. It generates pulses in a similar manner, advancing C633. Upon reaching a specified count, the drum controller closes the normally closed contacts, which halts the operation of the equipment. This method of control allows for precise timing and coordination among the different components of the production line, ensuring safety and efficiency.

The integration of a programmable logic controller (PLC) within this design enhances the system's flexibility and adaptability. The PLC can be programmed with various instructions tailored to specific operational needs, allowing for adjustments in the timing, sequence, and conditions under which equipment operates. This capability is particularly beneficial in environments where production requirements may change frequently, providing a dynamic solution to automation challenges.

Overall, the schematic design exemplifies a robust approach to automation in material handling and production processes, demonstrating the effectiveness of using a drum controller in conjunction with PLC technology for real-time operational management.According to the characteristics of the system, using the drum controller to achieve the above requirements, the design of the ladder as shown in FIG. As follows: 1) C631, C633 as a drum controller, which counts pulses generated by the T630, the pulse period is sequentially stopped at 5s C633. Use, its counting pulses generated by the T643, the pulse period is 5s. 2) after the start signal is active. T630 produces a pulse every 5s, C631 step, the corresponding pair of normally open contacts closed, the equipment along the sequence start.

3) After the stop signal is active, T633 produces a pulse every 5s, C633 step, and when it reaches the appropriate time, a corresponding pair of normally closed contacts closed, the equipment order to stop. (4) Conclusion In this case sand production line automatic control, for example, according to transport sand, sand and grind roller conveyor system flow characteristics, were used for the timer, drum controller, a shift register sequence control ladder the design of.

As can be seen, PLC in order to control side surfaces powerful, has a wealth of programming instructions, user program design flexible, convenient and very suitable delivery systems such as automation and control production lines.