Cool Electronics main page

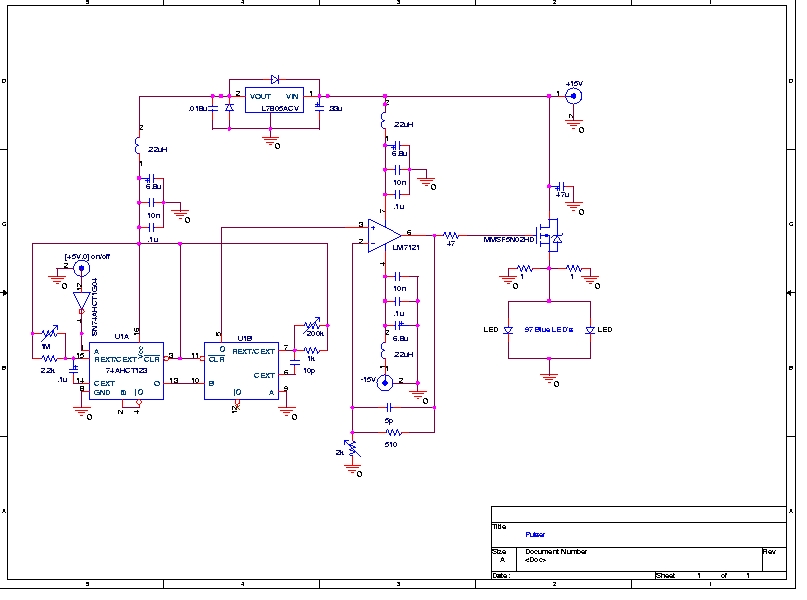

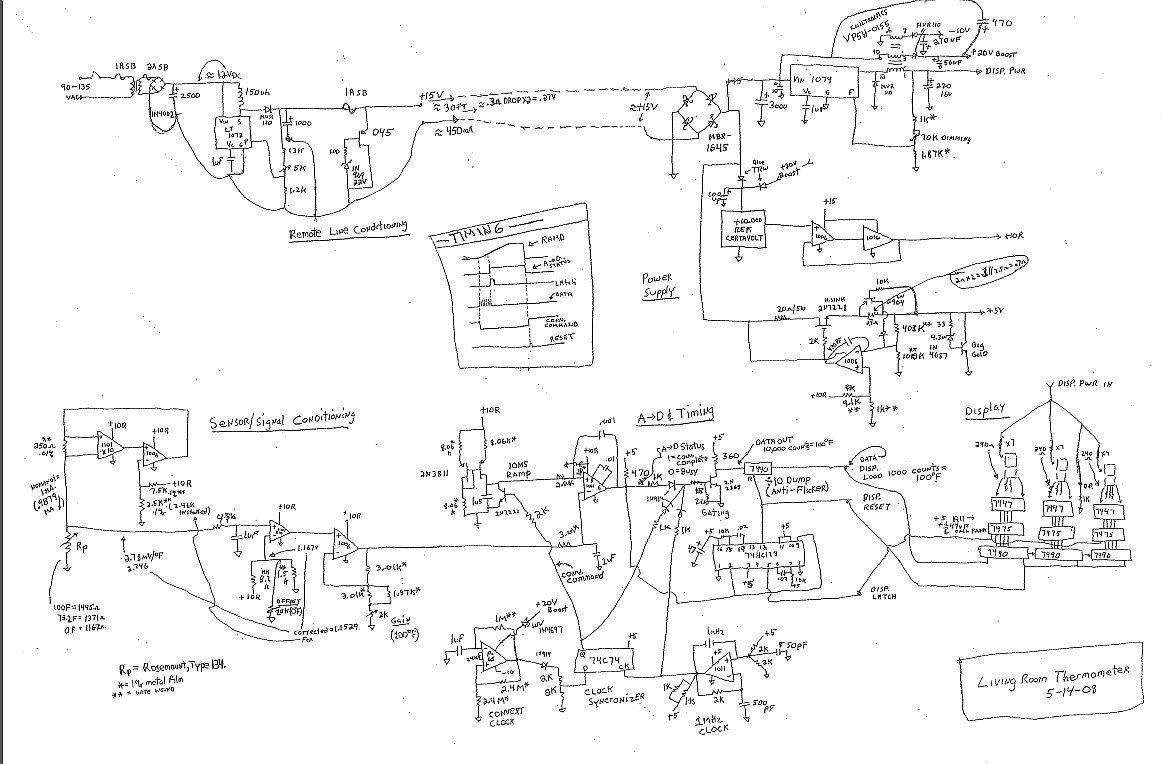

This laser is constructed on a polystyrene sheet. An aluminum foil layer acts as a ground plate (-), which is important for preionization. After that, the dielectric is placed on it, leaving 1 cm from each border of the foil. The dielectric thickness determines the maximum voltage, capacitance, and inductance. A thicker foil results in less capacitance, more voltage, and increased inductance (as the loop area increases). Many reports indicate that inductance grows faster than voltage, leading to reduced rise time (di/dt = V/L). Less capacitance also means less energy for the discharge. Many users report that thinner foil works better but has a limited lifetime and voltage strength, necessitating a closer spark gap. After placing the dielectric, capacitor plates made of aluminum foil are positioned, maintaining a distance of 0.5 cm from each other—closer will cause arcing, while farther will result in loss of preionization, which is essential for triggering the lasing process. The capacitor plates must be clamped with additional polystyrene sheets and secured with bolts and nuts. The electrodes are then placed in contact with the foil, with adjustable spacing. The charging inductor consists of several turns of enamel wire connecting the two plates and must be optimized for best performance (by adjusting the coil's width or compression). The spark gap should be positioned as close as possible to the ground plane to minimize inductance. The electrode distance must be adjusted for optimal performance. When lasing occurs, a strong fluorescence will appear on paper or a marker, and adding some fluorescein can help visualize the beam. The power supply must be current-limited to prevent firing hundreds of shots in a few seconds. The optimal repetition rate is one shot per second or more to minimize stress on the dielectric. This laser utilizes nitrogen present in the air (78%) as the active medium, but unlike many gas lasers, it operates at atmospheric pressure, eliminating the need for a vacuum pump. However, this feature has drawbacks, which will be explained through the quantum dynamics of this laser type. The laser operates by pumping electrons into a higher energy unstable state, which relaxes non-radiatively into another unstable state with a duration of several nanoseconds. It may then transition into a metastable state (lasting several milliseconds) that emits the characteristic wavelength with a spectral width related to the relaxation time. This metastable state absorbs UV light. The lasing transition occurs as the system moves from the unstable state to the metastable state, necessitating rapid pumping (on the order of nanoseconds) to achieve sufficient population inversion for lasing (via stimulated emission). In low-pressure nitrogen lasers, the upper state lifetime is tens of nanoseconds, while in atmospheric pressure nitrogen lasers, molecular collisions cause faster dissipation in a non-radiative manner, reducing the lifetime to a maximum of 2-3 nanoseconds. The lifetime [ns] can be calculated using the formula t = 36/(1+p/58) (as referenced in "Compact high-power TEA N2 laser" by B. S. Patel, Review Of Scientific Instruments, 49(9), Sept 1978) as a function of pressure [Torr]. This necessitates circuitry designed for fast rise times, requiring very low inductance (tens of nanohenries) and the highest possible voltages (without exceeding dielectric breakdown limits). The laser's capacitor plates, spark gap, and related components must be designed to minimize loop area to ensure low inductance; otherwise, the laser may not function effectively. Despite challenges, this laser has several advantages, including low cost and high gain, which eliminates the need for resonator mirrors (although their use can increase power and reduce divergence). This type of laser is known as a superradiant laser. Key factors that negatively impact this laser include inductance and humidity.

The construction of this laser system involves precise engineering and careful selection of materials to optimize performance. The aluminum ground plate serves as a critical component that aids in the preionization phase, ensuring that the dielectric material can effectively support the required electric fields. The choice of dielectric material and its thickness is paramount, as it directly influences the operational parameters such as voltage and capacitance. Thinner dielectrics may allow for faster rise times and better performance but come with trade-offs in terms of longevity and voltage handling capabilities.

The layout of the capacitor plates and the spark gap is designed to maintain specific distances that prevent arcing while ensuring sufficient preionization for effective lasing. The adjustable electrodes allow for fine-tuning during operation, which is essential for achieving optimal performance. The inductor's design must be optimized to ensure efficient energy transfer between the capacitor plates, while also minimizing inductance to enhance the laser's response time.

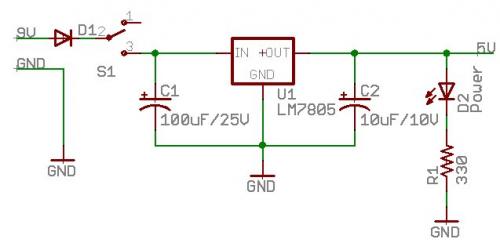

The operational principle of the laser leverages the unique properties of nitrogen as an active medium at atmospheric pressure, which simplifies the overall design by eliminating the need for complex vacuum systems. However, the rapid energy transitions and short-lived excited states necessitate a robust power supply capable of delivering high-voltage pulses with precise timing.

The laser's performance is also impacted by external factors such as humidity, which can affect the dielectric properties and overall efficiency. Therefore, it is critical to maintain environmental control to ensure consistent operation. The design considerations outlined above highlight the intricate balance between various components and their interactions, which are crucial for achieving effective lasing in this atmospheric pressure nitrogen laser system.This LASER is constructed on a polystirene sheet. An alluminium layer foil is placed and acts as a ground plate ( - ), this is important for preionization (i will discuss it later). After that the dielectic is placed on it leaving 1 cm from each border of the foil). The dielectric thickness determinates the max voltage, capacitance, and important , the inductance. Thicker foil means less capacitance, more voltage and more inductance(since the loop area increases). Many reports that the inductance grows faster than voltage so the risetime is reduced (di/dt = V/L). Less capacitance means also less energy for bang. Many peoples reports that thinner foil works better but has a limited lifetime and limited voltage strenght, so the spark gap must be brought closer.

After placing the dielectric I proceed to place the cap plates (separate) made with alu foil. The cap plates but be at 0. 5 cm from each other, not closer (or will arc-over), not farther (or we will loss preionization, that helps to trigger the lasing). The caps must be clamped with other polystirene sheets and with bolts/nuts. After that the electrodes were placed touching the foil and with adjustable distance. The charging inductor is some turns of enamel wire connecting the two plates, must be optimized for best performance (squeezing or wideing it).

The spark gap must be closer as possible to ground plane to minimize inductance (read further to know why). The electrodes distance must be adjusted for the best performance. When it will lase, a strong fluorescence will appear on paper or marker. Having some Fluorescein will visualize the beam. The power supply must be current limited or you will fire some hudred shots in a couple of seconds. The best repetition rate is 1shot/second or more, to put less stress possible on the dielectric. This LASER uses the nitrogen present in the air (78%) as the active medium but unlike many gas lasers it works at atmosfetic pressure.

This feature allows to eliminate the need of the a vacuum pump. There is a drawback though, i will explain it introducing the quantodynamics of this type of laser. The laser works by pumping the electrons in a higher energy unstable state, this state relaxes not-radiatively into another unstable state with time duration of some nanoseconds. After that it may fall into a metastable state (with duration of severan milliseconds) emitting the characteristic wavelenght with a spectral with related to the relaxing time.

This metastable state adsorbs UV. The lasing transition is defacto this passage from the unstable state to the metastable. This means that we have to pump the laser very quickly (il the order of nanoseconds) to have the population inversion enough to achieve the lasing threshold (by stimulated emission). While in low pressure nitrogen lasers the lifetime of the upper state is tens of nanoseconds, in the air atmosferic pressure laser, due to molecular collision causing faster disectitation in a non radiative way, the lifetime is 2-3 nanoseconds max.

The lifetime [ns] can ba calculated from this formula t = 36/(1+p/58) ([1] Compact high-power TEA N2 laser B. S. Patel Review Of Scientific Instruments, 49(9), Sept 1978) in function of pressure [Torr]. This means that the circuitry must be designed for fast risetime, needing very low inductance (tens of nanohenries ) and higher possible voltages (not too high or the dielectric will punch through).

The LASER capacitor plates, spark gap, etc must be designed for small loop area, to ensure lower possible inductance or the laser WILL NOT WORK good or at all. Believe me, i`ve been there, it is frustrating. Anyway this laser has many positive features also in addition of being cheap. It has a very high gain, eliminating the use of resonator mirrors (though using them gives higher power and less divergence), it is called a superradiant laser.

The enemies of this laser are inductance, humidity (s 🔗 External reference

The construction of this laser system involves precise engineering and careful selection of materials to optimize performance. The aluminum ground plate serves as a critical component that aids in the preionization phase, ensuring that the dielectric material can effectively support the required electric fields. The choice of dielectric material and its thickness is paramount, as it directly influences the operational parameters such as voltage and capacitance. Thinner dielectrics may allow for faster rise times and better performance but come with trade-offs in terms of longevity and voltage handling capabilities.

The layout of the capacitor plates and the spark gap is designed to maintain specific distances that prevent arcing while ensuring sufficient preionization for effective lasing. The adjustable electrodes allow for fine-tuning during operation, which is essential for achieving optimal performance. The inductor's design must be optimized to ensure efficient energy transfer between the capacitor plates, while also minimizing inductance to enhance the laser's response time.

The operational principle of the laser leverages the unique properties of nitrogen as an active medium at atmospheric pressure, which simplifies the overall design by eliminating the need for complex vacuum systems. However, the rapid energy transitions and short-lived excited states necessitate a robust power supply capable of delivering high-voltage pulses with precise timing.

The laser's performance is also impacted by external factors such as humidity, which can affect the dielectric properties and overall efficiency. Therefore, it is critical to maintain environmental control to ensure consistent operation. The design considerations outlined above highlight the intricate balance between various components and their interactions, which are crucial for achieving effective lasing in this atmospheric pressure nitrogen laser system.This LASER is constructed on a polystirene sheet. An alluminium layer foil is placed and acts as a ground plate ( - ), this is important for preionization (i will discuss it later). After that the dielectic is placed on it leaving 1 cm from each border of the foil). The dielectric thickness determinates the max voltage, capacitance, and important , the inductance. Thicker foil means less capacitance, more voltage and more inductance(since the loop area increases). Many reports that the inductance grows faster than voltage so the risetime is reduced (di/dt = V/L). Less capacitance means also less energy for bang. Many peoples reports that thinner foil works better but has a limited lifetime and limited voltage strenght, so the spark gap must be brought closer.

After placing the dielectric I proceed to place the cap plates (separate) made with alu foil. The cap plates but be at 0. 5 cm from each other, not closer (or will arc-over), not farther (or we will loss preionization, that helps to trigger the lasing). The caps must be clamped with other polystirene sheets and with bolts/nuts. After that the electrodes were placed touching the foil and with adjustable distance. The charging inductor is some turns of enamel wire connecting the two plates, must be optimized for best performance (squeezing or wideing it).

The spark gap must be closer as possible to ground plane to minimize inductance (read further to know why). The electrodes distance must be adjusted for the best performance. When it will lase, a strong fluorescence will appear on paper or marker. Having some Fluorescein will visualize the beam. The power supply must be current limited or you will fire some hudred shots in a couple of seconds. The best repetition rate is 1shot/second or more, to put less stress possible on the dielectric. This LASER uses the nitrogen present in the air (78%) as the active medium but unlike many gas lasers it works at atmosfetic pressure.

This feature allows to eliminate the need of the a vacuum pump. There is a drawback though, i will explain it introducing the quantodynamics of this type of laser. The laser works by pumping the electrons in a higher energy unstable state, this state relaxes not-radiatively into another unstable state with time duration of some nanoseconds. After that it may fall into a metastable state (with duration of severan milliseconds) emitting the characteristic wavelenght with a spectral with related to the relaxing time.

This metastable state adsorbs UV. The lasing transition is defacto this passage from the unstable state to the metastable. This means that we have to pump the laser very quickly (il the order of nanoseconds) to have the population inversion enough to achieve the lasing threshold (by stimulated emission). While in low pressure nitrogen lasers the lifetime of the upper state is tens of nanoseconds, in the air atmosferic pressure laser, due to molecular collision causing faster disectitation in a non radiative way, the lifetime is 2-3 nanoseconds max.

The lifetime [ns] can ba calculated from this formula t = 36/(1+p/58) ([1] Compact high-power TEA N2 laser B. S. Patel Review Of Scientific Instruments, 49(9), Sept 1978) in function of pressure [Torr]. This means that the circuitry must be designed for fast risetime, needing very low inductance (tens of nanohenries ) and higher possible voltages (not too high or the dielectric will punch through).

The LASER capacitor plates, spark gap, etc must be designed for small loop area, to ensure lower possible inductance or the laser WILL NOT WORK good or at all. Believe me, i`ve been there, it is frustrating. Anyway this laser has many positive features also in addition of being cheap. It has a very high gain, eliminating the use of resonator mirrors (though using them gives higher power and less divergence), it is called a superradiant laser.

The enemies of this laser are inductance, humidity (s 🔗 External reference