CR-5000 PCB Board Designer

The CR-5000 EDA design suite provides the most advanced PCB design functionality currently available. It is constraints driven, from schematic capture through board layout, to the output of manufacturing data. More: This means that the rules you apply early in the design process are maintained right through to manufacturing. So products are right first time, manufacturable first time, and get to market fast. A common component database is used throughout the process.

The CR-5000 EDA design suite is a sophisticated toolset for electronic design automation, specifically focused on printed circuit board (PCB) design. It employs a constraints-driven methodology that integrates the entire design process, starting from schematic capture and extending through to board layout and the generation of manufacturing data. This approach ensures that design rules and constraints defined at the outset are consistently applied throughout the entire workflow, which significantly enhances the reliability and manufacturability of the final product.

The suite facilitates a streamlined design process where engineers can utilize a common component database, ensuring that all components used in the design are standardized and easily accessible. This commonality not only helps in maintaining design integrity but also accelerates the design cycle, allowing for quicker iterations and modifications.

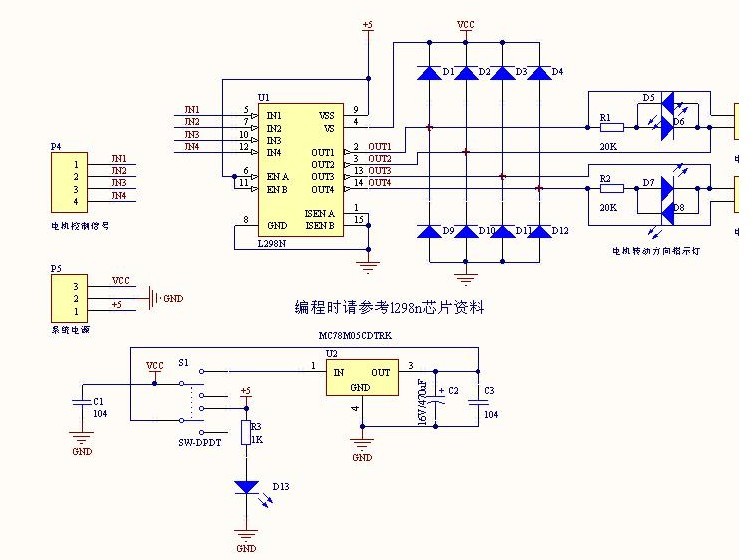

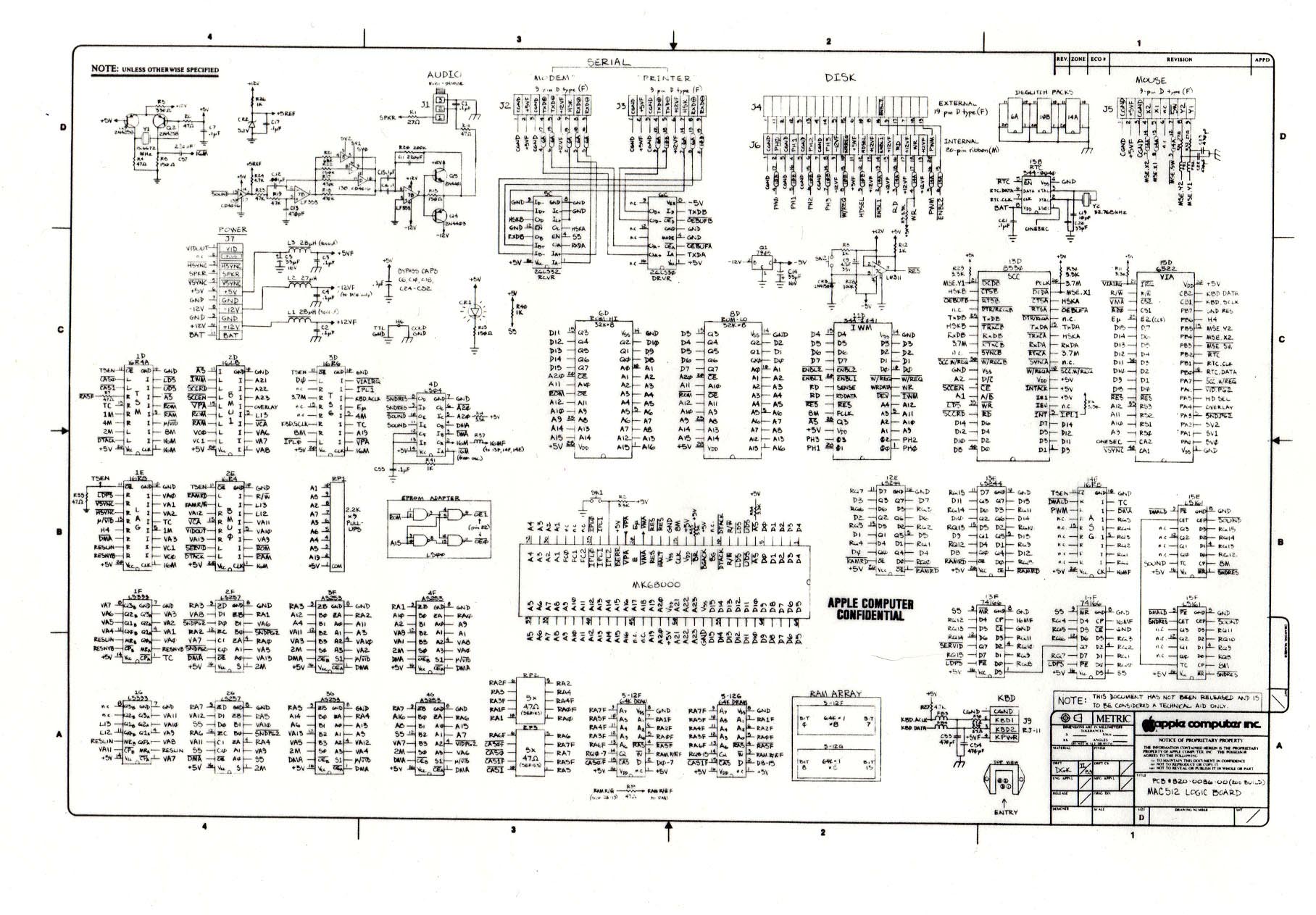

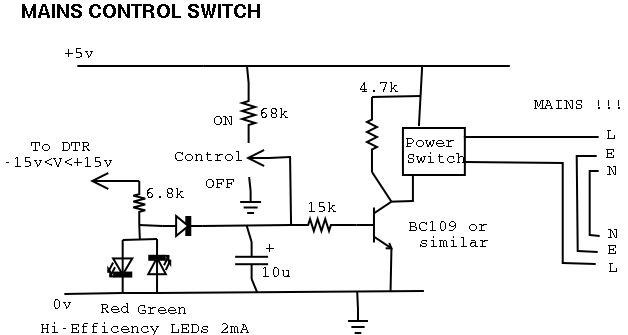

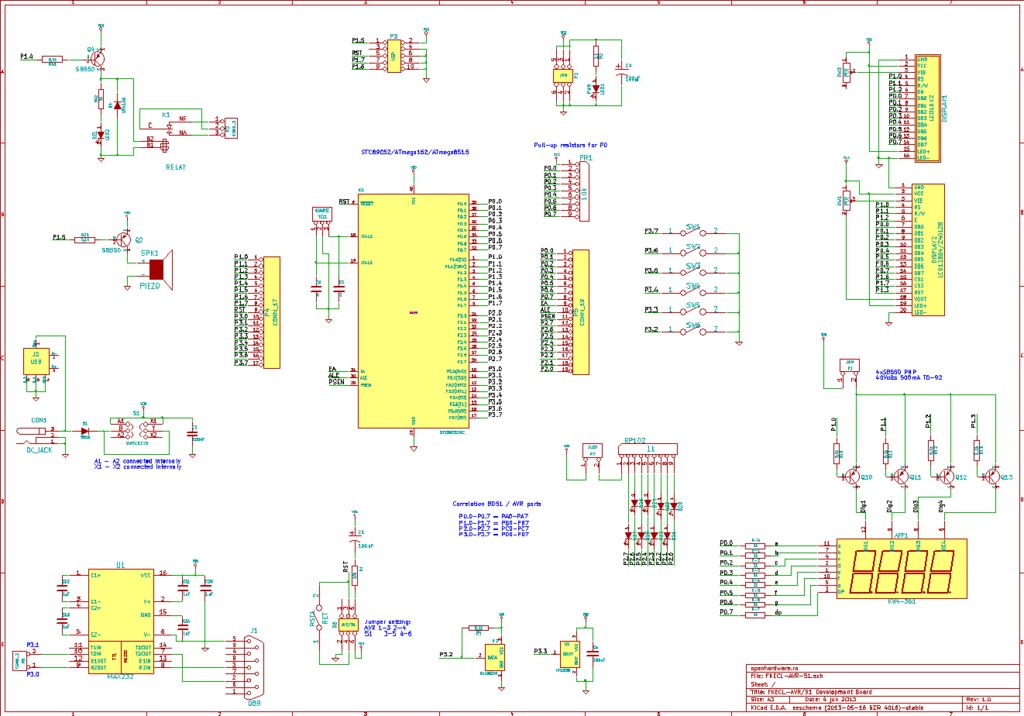

The schematic capture feature allows designers to create detailed circuit diagrams that accurately represent the electrical connections between components. This is followed by the board layout stage, where the physical arrangement of components on the PCB is optimized for both performance and manufacturability. The constraints-driven nature of the design suite means that any changes made during the layout phase will automatically update the schematic and vice versa, reducing the potential for errors.

Finally, the output of manufacturing data is a critical aspect of the CR-5000 suite, as it generates the necessary files required for PCB fabrication and assembly. This includes Gerber files, Bill of Materials (BOM), and assembly drawings, which are essential for ensuring that the manufactured product meets the original design specifications.

Overall, the CR-5000 EDA design suite is designed to enhance efficiency, reduce time-to-market, and ensure high-quality electronic products by employing a comprehensive and integrated approach to PCB design.The CR-5000 EDA design suite provides the most advanced PCB design functionality currently available. It is constraints driven, from schematic capture through board layout, to the output of manufacturing data.

This means that the rules you apply early in the design process are maintained right through to manufacturing. So products are right first time, manufacturable first time, and get to market fast. A common component database is used throughout the process, 🔗 External reference

The CR-5000 EDA design suite is a sophisticated toolset for electronic design automation, specifically focused on printed circuit board (PCB) design. It employs a constraints-driven methodology that integrates the entire design process, starting from schematic capture and extending through to board layout and the generation of manufacturing data. This approach ensures that design rules and constraints defined at the outset are consistently applied throughout the entire workflow, which significantly enhances the reliability and manufacturability of the final product.

The suite facilitates a streamlined design process where engineers can utilize a common component database, ensuring that all components used in the design are standardized and easily accessible. This commonality not only helps in maintaining design integrity but also accelerates the design cycle, allowing for quicker iterations and modifications.

The schematic capture feature allows designers to create detailed circuit diagrams that accurately represent the electrical connections between components. This is followed by the board layout stage, where the physical arrangement of components on the PCB is optimized for both performance and manufacturability. The constraints-driven nature of the design suite means that any changes made during the layout phase will automatically update the schematic and vice versa, reducing the potential for errors.

Finally, the output of manufacturing data is a critical aspect of the CR-5000 suite, as it generates the necessary files required for PCB fabrication and assembly. This includes Gerber files, Bill of Materials (BOM), and assembly drawings, which are essential for ensuring that the manufactured product meets the original design specifications.

Overall, the CR-5000 EDA design suite is designed to enhance efficiency, reduce time-to-market, and ensure high-quality electronic products by employing a comprehensive and integrated approach to PCB design.The CR-5000 EDA design suite provides the most advanced PCB design functionality currently available. It is constraints driven, from schematic capture through board layout, to the output of manufacturing data.

This means that the rules you apply early in the design process are maintained right through to manufacturing. So products are right first time, manufacturable first time, and get to market fast. A common component database is used throughout the process, 🔗 External reference