DC Drill Speed Controller Circuit

This DC drill speed controller circuit allows for the adjustment of the rotational speed of a drilling machine. A mini-drill machine is always...

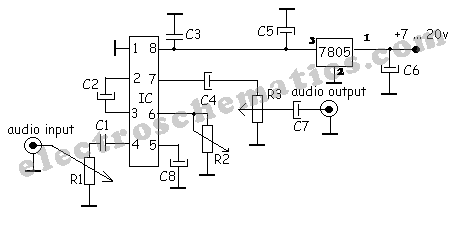

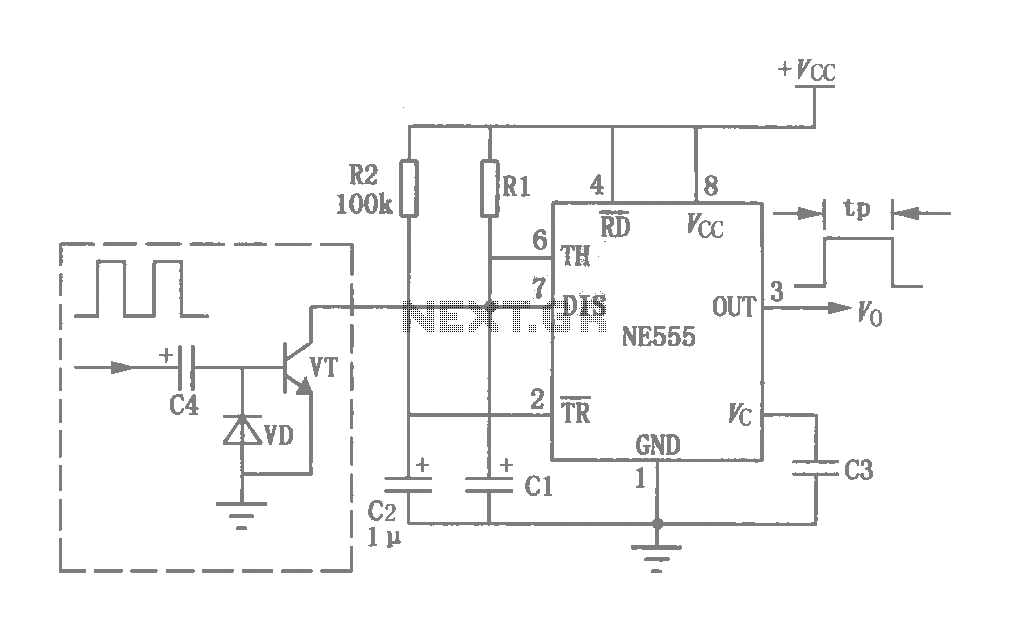

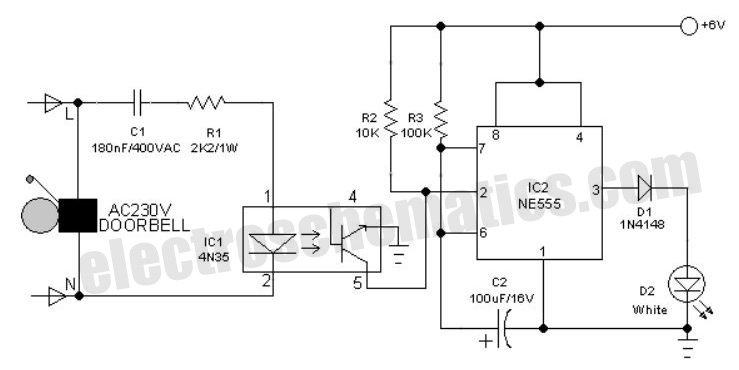

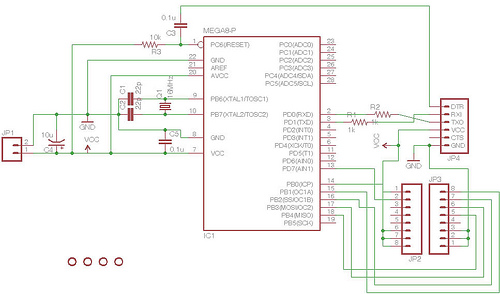

This circuit utilizes a pulse-width modulation (PWM) technique to control the speed of a DC motor, which is commonly found in mini-drill machines. The primary components of the circuit include a microcontroller or a dedicated PWM controller, a power transistor or MOSFET, a diode for back EMF protection, and a potentiometer for speed adjustment.

The microcontroller generates a PWM signal that varies the duty cycle, effectively controlling the average voltage supplied to the motor. The transistor or MOSFET acts as a switch, turning the motor on and off rapidly based on the PWM signal. The diode is connected in parallel with the motor to protect the circuit from voltage spikes generated when the motor is switched off, a phenomenon known as back electromotive force (back EMF).

The potentiometer allows the user to set the desired speed by varying the resistance in the circuit, which in turn adjusts the PWM signal's duty cycle. This setup provides a smooth and efficient way to control the speed of the drill, enhancing the versatility and usability of the mini-drill machine for various applications.

When designing this circuit, considerations should be made regarding the power ratings of the components to ensure they can handle the operational current and voltage. Additionally, proper heat dissipation methods should be implemented for the transistor or MOSFET to prevent overheating during prolonged use.With the help of this DC drill speed controller circuit you can control the number of revolutions of your drilling machine. A mini-drill machine is always.. 🔗 External reference

This circuit utilizes a pulse-width modulation (PWM) technique to control the speed of a DC motor, which is commonly found in mini-drill machines. The primary components of the circuit include a microcontroller or a dedicated PWM controller, a power transistor or MOSFET, a diode for back EMF protection, and a potentiometer for speed adjustment.

The microcontroller generates a PWM signal that varies the duty cycle, effectively controlling the average voltage supplied to the motor. The transistor or MOSFET acts as a switch, turning the motor on and off rapidly based on the PWM signal. The diode is connected in parallel with the motor to protect the circuit from voltage spikes generated when the motor is switched off, a phenomenon known as back electromotive force (back EMF).

The potentiometer allows the user to set the desired speed by varying the resistance in the circuit, which in turn adjusts the PWM signal's duty cycle. This setup provides a smooth and efficient way to control the speed of the drill, enhancing the versatility and usability of the mini-drill machine for various applications.

When designing this circuit, considerations should be made regarding the power ratings of the components to ensure they can handle the operational current and voltage. Additionally, proper heat dissipation methods should be implemented for the transistor or MOSFET to prevent overheating during prolonged use.With the help of this DC drill speed controller circuit you can control the number of revolutions of your drilling machine. A mini-drill machine is always.. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713