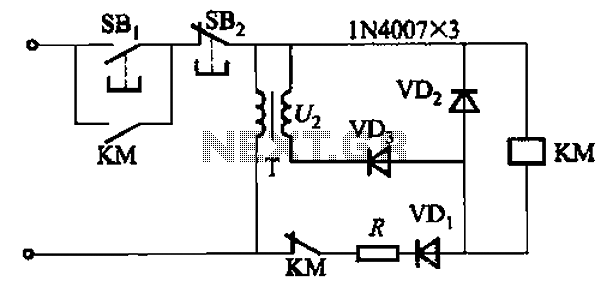

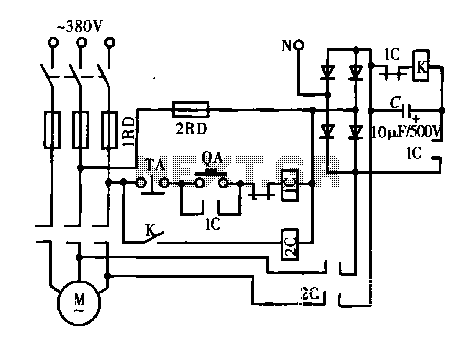

DC motor dynamic braking circuit

A DC motor is depicted in a dynamic braking circuit. When the stop button (SB2) is pressed, the contactor (KM1) is deactivated, causing its movable contact to disconnect, which interrupts the electrical voltage. Additionally, relay (KV) is activated, closing its contacts. This action engages the electric brake contactor (KM2), which connects a braking resistor (R) in parallel across the armature. Consequently, the direction of the excitation current is altered, generating a braking torque that allows the motor to stop rapidly. Once the back EMF voltage of the armature falls below the release voltage of relay (KV), the relay deactivates, causing contactor (KM2) to disconnect and completing the braking process.

The described dynamic braking circuit for a DC motor utilizes a series of components to effectively manage the motor's stopping process. The circuit begins with the operation of the stop button (SB2), which initiates the braking sequence. Pressing this button results in the deactivation of contactor (KM1), which is crucial for cutting off the supply voltage to the motor. This interruption is essential to prevent further rotation of the motor.

Simultaneously, relay (KV) is activated, closing its contacts to engage the electric brake contactor (KM2). This contactor plays a vital role in connecting a braking resistor (R) across the armature terminals. The inclusion of this resistor is significant as it allows for the dissipation of energy generated during the motor's deceleration. When the excitation current is redirected, the motor generates a braking torque, which aids in rapidly reducing the motor's speed.

As the motor slows down, the back EMF produced by the armature decreases. This back EMF is a critical parameter, as it reflects the motor's speed and the energy being fed back into the circuit. When this back EMF drops below the predetermined release voltage of relay (KV), the relay releases, causing contactor (KM2) to deactivate. This action signifies the end of the braking process, effectively stopping the motor.

The dynamic braking circuit is an efficient method for managing the rapid deceleration of DC motors, ensuring both safety and performance in various applications. Proper understanding and implementation of each component are essential for achieving optimal braking performance.DC motor is shown in dynamic braking circuit. Braking, press the stop button SB2, the contactor KM1 missing, and released its movable contact connected off, electrical voltage relay KV eligible actions, which make contacts closed, the electric brake contactor KM2 eligible action will braking resistor R is connected in parallel at both ends of the armature, then changed direction due to the excitation current, the torque produced by the motor brake torque, the motor stops quickly. When the armature back EMF voltage is lower than the release voltage relay KV, KV release, so KM2 missing, and released the end of the braking process.

The described dynamic braking circuit for a DC motor utilizes a series of components to effectively manage the motor's stopping process. The circuit begins with the operation of the stop button (SB2), which initiates the braking sequence. Pressing this button results in the deactivation of contactor (KM1), which is crucial for cutting off the supply voltage to the motor. This interruption is essential to prevent further rotation of the motor.

Simultaneously, relay (KV) is activated, closing its contacts to engage the electric brake contactor (KM2). This contactor plays a vital role in connecting a braking resistor (R) across the armature terminals. The inclusion of this resistor is significant as it allows for the dissipation of energy generated during the motor's deceleration. When the excitation current is redirected, the motor generates a braking torque, which aids in rapidly reducing the motor's speed.

As the motor slows down, the back EMF produced by the armature decreases. This back EMF is a critical parameter, as it reflects the motor's speed and the energy being fed back into the circuit. When this back EMF drops below the predetermined release voltage of relay (KV), the relay releases, causing contactor (KM2) to deactivate. This action signifies the end of the braking process, effectively stopping the motor.

The dynamic braking circuit is an efficient method for managing the rapid deceleration of DC motors, ensuring both safety and performance in various applications. Proper understanding and implementation of each component are essential for achieving optimal braking performance.DC motor is shown in dynamic braking circuit. Braking, press the stop button SB2, the contactor KM1 missing, and released its movable contact connected off, electrical voltage relay KV eligible actions, which make contacts closed, the electric brake contactor KM2 eligible action will braking resistor R is connected in parallel at both ends of the armature, then changed direction due to the excitation current, the torque produced by the motor brake torque, the motor stops quickly. When the armature back EMF voltage is lower than the release voltage relay KV, KV release, so KM2 missing, and released the end of the braking process.