DDS-based automatic tracking frequency ultrasonic generator

Ultrasonic cleaning primarily relies on the phenomenon of ultrasonic cavitation. In the presence of a sound field, liquid bubbles undergo high-frequency micro-vibrations. When the sound pressure reaches a specific threshold, air bubbles grow rapidly and then collapse suddenly, creating a strong shock wave due to the collision of the liquid. Although the displacement and velocity of these bubbles are minimal, their acceleration can reach thousands of times the local atmospheric pressure. This process effectively damages, dislodges, separates, and emulsifies contaminants from surfaces, resulting in rapid and efficient cleaning. Ultrasonic cleaning is globally recognized as one of the most effective cleaning methods, achieving cleaning efficiencies above 98% and reaching the highest standards of cleanliness.

Ultrasonic cleaning equipment consists mainly of an ultrasonic generator and an ultrasonic transducer. The ultrasonic generator plays a crucial role by supplying energy to the transducer, which must not only provide sufficient power but also operate at a frequency that resonates with the transducer's resonant frequency. However, the resonant frequency of the transducer can change over time due to factors such as heat and aging. Typically, ultrasonic generators on the market require manual adjustment of the output signal to align with the transducer’s resonant frequency. To address this issue, a DDS (Direct Digital Frequency Synthesizer) based automatic tracking frequency generator has been developed, enabling the output signal frequency to automatically adjust to the transducer's resonant frequency and maintain high efficiency during operation.

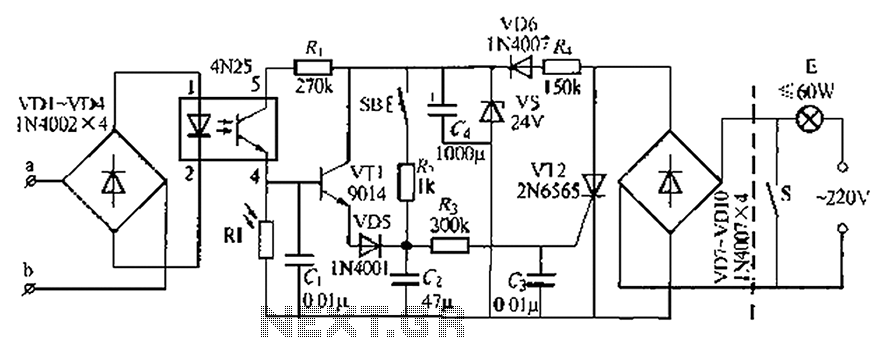

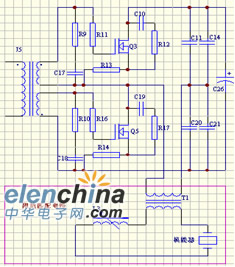

The design of the ultrasonic generator incorporates a DDS-based frequency automatic tracking circuit. The overall system block diagram illustrates the various components, including the DDS signal generator circuit, power amplifier, matching circuits, current feedback circuit, microcontroller, and additional external circuits. The working principle of the system involves the use of a DDS chip (AD9832) controlled by a microcontroller to generate a sine wave signal at a specific frequency. This sine wave is processed through a primary shaping amplifier and then applied to a transformer to produce two phase-contrast square-wave signals that drive a complementary push-pull power amplifier circuit composed of N-channel MOSFETs. The output is further transformed through an output transformer and an adjustable matching circuit to drive the piezoelectric transducer.

During operation, the transducer's performance is monitored through a current sensor, which provides feedback on the work current back to the system. The microcontroller utilizes this feedback to adjust the frequency output of the DDS chip, ensuring that the transducer operates continuously at its resonant frequency, thereby enhancing its efficiency. The DDS chip generates frequency signals through a Numerically Controlled Oscillator (NCO), controlling the phase of the sine wave. The DDS system includes an internal reference clock circuit, frequency accumulator, phase accumulator, magnitude/phase conversion circuit, digital-to-analog converters (DAC), and a low-pass filter (LPF). The design employs the AD9832 chip, a phase-accumulating numerical control oscillator with a built-in sine look-up table and a 10-bit DAC, capable of operating with a maximum clock frequency of 25 MHz.Ultrasonic Cleaning the main role in the use of ultrasonic cavitation. Role in the sound field, there is liquid in the bubble will have high-frequency micro-vibration, when the sound pressure reaches a certain value, the rapid growth of air bubbles and then suddenly closed, liquid collision between a strong shock wave, although the displacement, velocity are very small, But the acceleration is very large, up to thousands of local atmospheric pressure, so that cleaning of the dirt surface membrane damage, spalling, separation and emulsification, so as to achieve a rapid and efficient cleaning results. At present, ultrasonic cleaning has been internationally recognized as the current most efficient, most effective way of cleaning, the cleaning efficiency above 98%, cleaning cleanliness also reached the highest level.

Ultrasonic cleaning equipment by the ultrasonic generator and ultrasonic transducer component. Which ultrasonic cleaning equipment ultrasonic generator is an important part of the process responsible for the work to the ultrasonic transducer to provide energy. Transducer in order to achieve high efficiency, in addition to providing adequate power, but also the frequency generator with the transducer resonant frequency of the same.

But the transducer resonant frequency in the course of their work are usually due to heat, aging and other factors change, and the ultrasonic generator on the market are usually by manually adjusting the output signal to track the frequency of ultrasonic transducer resonant frequency, in order to resolve this problem, this paper has been developed based on DDS (direct digital frequency synthesizer) automatic tracking of the ultrasound frequency generator, so that the output signal frequency generator to automatically track the transducer resonant frequency, so that the transducer in the workplace the process has always been maintained at a high-efficiency state. In the design of ultrasonic generator in order to make the output frequency can be real-time tracking of the transducer resonant frequency, the design of a DDS-based frequency of automatic tracking circuit.

Overall system block diagram shown in Figure 1. The system by the DDS signal generator circuit, power amplifier, matching circuits, current feedback circuit, single-chip control and some of the external circuit. System block diagram shown in Figure 1. The working principle of the whole system as follows: DDS chip AD9832 single-chip microcomputer to control a certain frequency of the sine wave signal, the sine wave signal and primary shaping amplifier is added after the primary coil of a transformer isolation of both ends of both sides of a sense of isolation transformer give birth to the two phase-contrast square-wave signal to drive two N-channel MOS tube composed of half-bridge complementary push-pull power amplifier circuit, the latter through the output transformer and adjustable matching circuit composed of inductor-driven piezoelectric transducer browser.

Transducer work in a timely manner through the current sensor during the transducer back to the work of current-feedback, single-chip microcomputer in accordance with feedback information corresponding to the DDS chip to control the frequency of the corresponding output signal to transducer always work in the resonance point effectively improve their work efficiency. Frequency signals generated by the DDS chip to complete. The working principle of DDS is the way NCO frequency, phase of the sine wave can be controlled. Generally include the internal reference clock circuit, the frequency accumulator, phase accumulator, magnitude / phase conversion circuit, D / A converters and low-pass filter (LPF).

The design of this DDS using AD9832 chip, AD9832 is a cumulative numerical control oscillator phase, built-sine look-up table and a 10-bit D / A converters of the CMOS chip. access to the largest clock 25MHz, the m 🔗 External reference

Ultrasonic cleaning equipment consists mainly of an ultrasonic generator and an ultrasonic transducer. The ultrasonic generator plays a crucial role by supplying energy to the transducer, which must not only provide sufficient power but also operate at a frequency that resonates with the transducer's resonant frequency. However, the resonant frequency of the transducer can change over time due to factors such as heat and aging. Typically, ultrasonic generators on the market require manual adjustment of the output signal to align with the transducer’s resonant frequency. To address this issue, a DDS (Direct Digital Frequency Synthesizer) based automatic tracking frequency generator has been developed, enabling the output signal frequency to automatically adjust to the transducer's resonant frequency and maintain high efficiency during operation.

The design of the ultrasonic generator incorporates a DDS-based frequency automatic tracking circuit. The overall system block diagram illustrates the various components, including the DDS signal generator circuit, power amplifier, matching circuits, current feedback circuit, microcontroller, and additional external circuits. The working principle of the system involves the use of a DDS chip (AD9832) controlled by a microcontroller to generate a sine wave signal at a specific frequency. This sine wave is processed through a primary shaping amplifier and then applied to a transformer to produce two phase-contrast square-wave signals that drive a complementary push-pull power amplifier circuit composed of N-channel MOSFETs. The output is further transformed through an output transformer and an adjustable matching circuit to drive the piezoelectric transducer.

During operation, the transducer's performance is monitored through a current sensor, which provides feedback on the work current back to the system. The microcontroller utilizes this feedback to adjust the frequency output of the DDS chip, ensuring that the transducer operates continuously at its resonant frequency, thereby enhancing its efficiency. The DDS chip generates frequency signals through a Numerically Controlled Oscillator (NCO), controlling the phase of the sine wave. The DDS system includes an internal reference clock circuit, frequency accumulator, phase accumulator, magnitude/phase conversion circuit, digital-to-analog converters (DAC), and a low-pass filter (LPF). The design employs the AD9832 chip, a phase-accumulating numerical control oscillator with a built-in sine look-up table and a 10-bit DAC, capable of operating with a maximum clock frequency of 25 MHz.Ultrasonic Cleaning the main role in the use of ultrasonic cavitation. Role in the sound field, there is liquid in the bubble will have high-frequency micro-vibration, when the sound pressure reaches a certain value, the rapid growth of air bubbles and then suddenly closed, liquid collision between a strong shock wave, although the displacement, velocity are very small, But the acceleration is very large, up to thousands of local atmospheric pressure, so that cleaning of the dirt surface membrane damage, spalling, separation and emulsification, so as to achieve a rapid and efficient cleaning results. At present, ultrasonic cleaning has been internationally recognized as the current most efficient, most effective way of cleaning, the cleaning efficiency above 98%, cleaning cleanliness also reached the highest level.

Ultrasonic cleaning equipment by the ultrasonic generator and ultrasonic transducer component. Which ultrasonic cleaning equipment ultrasonic generator is an important part of the process responsible for the work to the ultrasonic transducer to provide energy. Transducer in order to achieve high efficiency, in addition to providing adequate power, but also the frequency generator with the transducer resonant frequency of the same.

But the transducer resonant frequency in the course of their work are usually due to heat, aging and other factors change, and the ultrasonic generator on the market are usually by manually adjusting the output signal to track the frequency of ultrasonic transducer resonant frequency, in order to resolve this problem, this paper has been developed based on DDS (direct digital frequency synthesizer) automatic tracking of the ultrasound frequency generator, so that the output signal frequency generator to automatically track the transducer resonant frequency, so that the transducer in the workplace the process has always been maintained at a high-efficiency state. In the design of ultrasonic generator in order to make the output frequency can be real-time tracking of the transducer resonant frequency, the design of a DDS-based frequency of automatic tracking circuit.

Overall system block diagram shown in Figure 1. The system by the DDS signal generator circuit, power amplifier, matching circuits, current feedback circuit, single-chip control and some of the external circuit. System block diagram shown in Figure 1. The working principle of the whole system as follows: DDS chip AD9832 single-chip microcomputer to control a certain frequency of the sine wave signal, the sine wave signal and primary shaping amplifier is added after the primary coil of a transformer isolation of both ends of both sides of a sense of isolation transformer give birth to the two phase-contrast square-wave signal to drive two N-channel MOS tube composed of half-bridge complementary push-pull power amplifier circuit, the latter through the output transformer and adjustable matching circuit composed of inductor-driven piezoelectric transducer browser.

Transducer work in a timely manner through the current sensor during the transducer back to the work of current-feedback, single-chip microcomputer in accordance with feedback information corresponding to the DDS chip to control the frequency of the corresponding output signal to transducer always work in the resonance point effectively improve their work efficiency. Frequency signals generated by the DDS chip to complete. The working principle of DDS is the way NCO frequency, phase of the sine wave can be controlled. Generally include the internal reference clock circuit, the frequency accumulator, phase accumulator, magnitude / phase conversion circuit, D / A converters and low-pass filter (LPF).

The design of this DDS using AD9832 chip, AD9832 is a cumulative numerical control oscillator phase, built-sine look-up table and a 10-bit D / A converters of the CMOS chip. access to the largest clock 25MHz, the m 🔗 External reference