DIY video dolly stepper motor driver

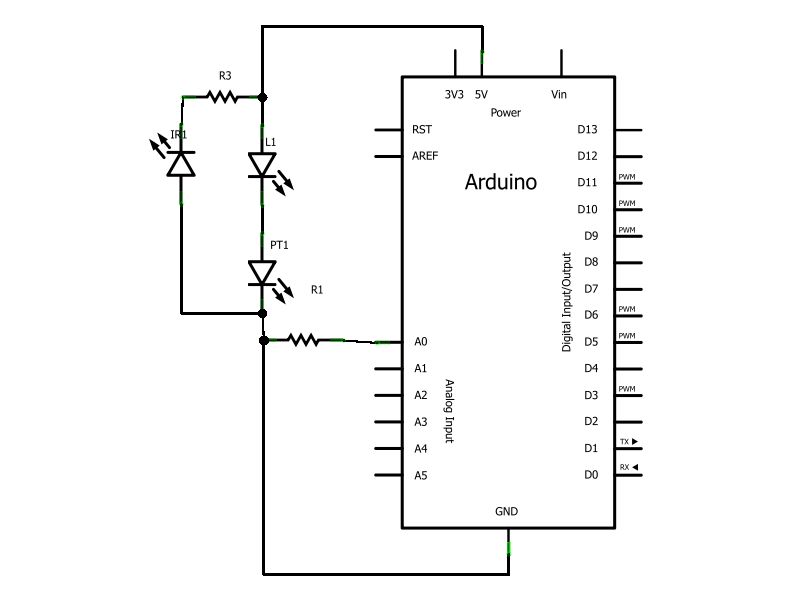

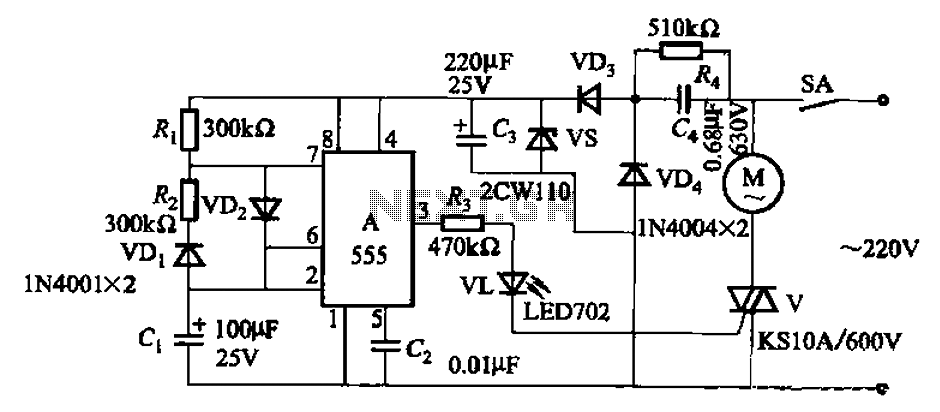

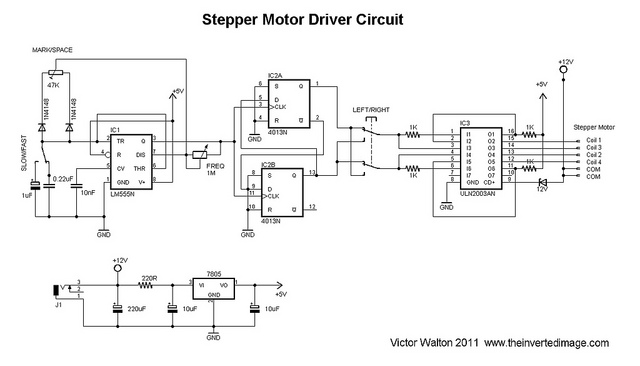

The commonly used 555 timer is configured for a variable mark/space ratio, which is essential for this application. Additionally, two D-type flip-flops (4013) are employed to provide the necessary count for the ULN2003 stepper motor driver. ULN2003 components may be challenging to source from standard parts suppliers; however, alternatives like the ULN2803 can effectively serve the same purpose. The 4013 generates the 0011 and 0110 counts required for the ULN2003 operation, while a DPDT switch facilitates forward and backward motion by simply reversing the connections. The ULN2003 is arranged to provide dual coil drive for a unipolar stepper motor, enhancing torque to power the dolly. A 7805 voltage regulator supplies 5 volts to the 555 timer and flip-flops, significantly improving the stability of the 555 timer. The stepper motor is powered by a 12-volt battery pack. The timing capacitors for the 555 timer include a 1 µF tantalum capacitor and a 0.22 µF mylar capacitor, which further contribute to stability. Although a 4017 decade counter was initially considered to implement half-step driving for the stepper motor, a faulty output from the salvaged counter led to the abandonment of that idea. Future enhancements may still be possible, but no substantial resources have been expended thus far.

The circuit utilizes a 555 timer in astable mode to generate a pulse-width modulation (PWM) signal, which controls the timing of the stepper motor's operation. The variable mark/space ratio allows for precise control over the speed of the motor by adjusting the duty cycle of the PWM signal. The D-type flip-flops (4013) are utilized to create a binary count sequence, which is essential for driving the ULN2003 stepper motor driver. The ULN2003, a high-voltage, high-current Darlington driver, is specifically designed to control inductive loads such as stepper motors.

The DPDT switch plays a crucial role in the direction control of the stepper motor. By reversing the connections, the switch allows the motor to rotate in either direction, providing flexibility in operation. The dual coil drive configuration of the ULN2003 ensures that the unipolar stepper motor receives adequate power, enhancing its torque and performance, particularly when moving heavier loads like a dolly.

The 7805 voltage regulator is essential for providing a stable 5V supply to the digital components, ensuring reliable operation of the 555 timer and flip-flops. The choice of timing capacitors, including the tantalum and mylar types, is critical for maintaining the stability of the 555 timer's output, which directly influences the performance of the entire circuit.

In summary, this circuit design effectively combines a 555 timer, D-type flip-flops, and a ULN2003 driver to create a robust stepper motor control system suitable for applications such as camera dolly systems. Future iterations could explore additional features, such as half-step driving with a decade counter, to further enhance control and functionality.The ubiquitous 555 timer, (hooked up for variable mark/space ratio, if you build one you`ll find out why it`s needed), and a couple of D type flip-flops, (4013), to provide the count for the ULN2003 stepper motor driver. (ULN2003`s might be hard to find off the parts shelf nowadays, this one was stripped from an old printer board but a ULN2803 or

similar will do a nice job). The 4013 provides a 0011 and 0110 count required for the boot-strapped ULN2003, a DPDT switch providing forward and backward drive, (by simpling reversing the connections). The ULN2003 is hooked up in such a way as to provide dual coil drive for a unipolar stepper motor so that it gains more torque to drive the `dolly`.

A 7805 regulator to provide 5 volts for the 555 timer and flip flop, (the stability of the 555 timer is much improved by doing this!), and the 12 volt from the battery pack driving the stepper motor. The timing capacitors on the 555 are a tantulum, (1uF), and myler, (0. 22uF), types to further aid stability. Could it be better Yes, definately. I was going to use a 4017 decade counter hooked up with diode logic to provide half step driving to the stepper motor with a further output to fire the camera when the rail is not moving, but the scrap 4017 counter I lifted from a scrap board had a faulty output so that idea was put to one side.

Who knows, maybe I`ll get into this and put something more luxurious together. Or maybe not and I wouldn`t have wasted too much time and definitely no money. Nice. [url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr

[url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr  [url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr

[url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr  [url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr

[url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr  [url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr

[url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr  [url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr

[url= [url= video dolly stepper motor driver[/url] by [url= W. [/url], on Flickr  🔗 External reference

🔗 External reference

The circuit utilizes a 555 timer in astable mode to generate a pulse-width modulation (PWM) signal, which controls the timing of the stepper motor's operation. The variable mark/space ratio allows for precise control over the speed of the motor by adjusting the duty cycle of the PWM signal. The D-type flip-flops (4013) are utilized to create a binary count sequence, which is essential for driving the ULN2003 stepper motor driver. The ULN2003, a high-voltage, high-current Darlington driver, is specifically designed to control inductive loads such as stepper motors.

The DPDT switch plays a crucial role in the direction control of the stepper motor. By reversing the connections, the switch allows the motor to rotate in either direction, providing flexibility in operation. The dual coil drive configuration of the ULN2003 ensures that the unipolar stepper motor receives adequate power, enhancing its torque and performance, particularly when moving heavier loads like a dolly.

The 7805 voltage regulator is essential for providing a stable 5V supply to the digital components, ensuring reliable operation of the 555 timer and flip-flops. The choice of timing capacitors, including the tantalum and mylar types, is critical for maintaining the stability of the 555 timer's output, which directly influences the performance of the entire circuit.

In summary, this circuit design effectively combines a 555 timer, D-type flip-flops, and a ULN2003 driver to create a robust stepper motor control system suitable for applications such as camera dolly systems. Future iterations could explore additional features, such as half-step driving with a decade counter, to further enhance control and functionality.The ubiquitous 555 timer, (hooked up for variable mark/space ratio, if you build one you`ll find out why it`s needed), and a couple of D type flip-flops, (4013), to provide the count for the ULN2003 stepper motor driver. (ULN2003`s might be hard to find off the parts shelf nowadays, this one was stripped from an old printer board but a ULN2803 or

similar will do a nice job). The 4013 provides a 0011 and 0110 count required for the boot-strapped ULN2003, a DPDT switch providing forward and backward drive, (by simpling reversing the connections). The ULN2003 is hooked up in such a way as to provide dual coil drive for a unipolar stepper motor so that it gains more torque to drive the `dolly`.

A 7805 regulator to provide 5 volts for the 555 timer and flip flop, (the stability of the 555 timer is much improved by doing this!), and the 12 volt from the battery pack driving the stepper motor. The timing capacitors on the 555 are a tantulum, (1uF), and myler, (0. 22uF), types to further aid stability. Could it be better Yes, definately. I was going to use a 4017 decade counter hooked up with diode logic to provide half step driving to the stepper motor with a further output to fire the camera when the rail is not moving, but the scrap 4017 counter I lifted from a scrap board had a faulty output so that idea was put to one side.

Who knows, maybe I`ll get into this and put something more luxurious together. Or maybe not and I wouldn`t have wasted too much time and definitely no money. Nice.