A3952S stepper motor controller circuit design

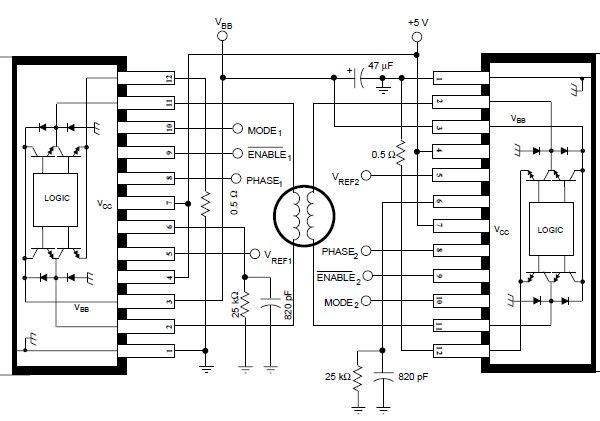

The A3952S stepper motor controller, designed by Allegro MicroSystems, can be utilized to create a straightforward and effective motor driver circuit suitable for various electronic applications. This controller supports continuous output currents of up to 2 A and operates within a voltage range of up to 50 V. It features internal fixed off-time PWM current control circuitry that regulates the maximum load current to a specified value. The MODE terminal allows for the optimization of device performance in microstepping and sinusoidal stepper motor drive applications. In scenarios where the average load current increases, slow-decay mode is employed to minimize switching losses in the device and iron losses in the motor. Thermal performance in high load current and/or high duty cycle applications can be enhanced by incorporating external diodes in parallel with the internal diodes. For internal PWM slow-decay applications, only the two top-side (flyback) diodes need to be added. In cases of internal fast-decay PWM or external PHASE or ENABLE input PWM applications, all four external diodes should be included to achieve maximum junction temperature reduction.

The A3952S stepper motor controller is an integrated circuit designed to drive stepper motors efficiently and effectively. This device is particularly advantageous for applications requiring precise control of motor position and speed. The controller's ability to handle continuous output currents of up to 2 A makes it suitable for a variety of stepper motors, from small to medium-sized applications.

The internal fixed off-time PWM current control circuitry is a key feature, as it allows the user to set a maximum load current, which is crucial for protecting the motor and the driver from overheating and damage. The use of the MODE terminal provides flexibility in operation, enabling the selection of different modes for microstepping, which enhances the smoothness of motor operation and reduces vibrations.

In applications where the load current is subject to rapid changes, the implementation of slow-decay mode is beneficial. This mode helps in reducing the switching losses that occur during the operation of the motor, thereby improving overall efficiency. Additionally, the reduction of iron losses in the motor contributes to better performance and longevity of the motor.

For applications that demand high performance under heavy loads or continuous duty cycles, the thermal management of the A3952S is critical. By adding external diodes in parallel with the internal diodes, heat dissipation can be significantly improved. This is particularly important in high-current scenarios where excessive heat can lead to failure of the device. The recommendation to use only the top-side diodes for slow-decay applications simplifies the design while ensuring adequate thermal performance. Conversely, for fast-decay PWM applications, the inclusion of all four external diodes is essential to maintain optimal thermal conditions and prevent junction temperature from exceeding safe limits.

In summary, the A3952S stepper motor controller is a versatile and efficient solution for driving stepper motors in various electronic applications, providing features that enhance performance, efficiency, and thermal management.Using the A3952S stepper motor controller designed by Allegro MicroSystems can be designed a very simple and useful motor driver circuit that can be used in many electronic applications. A3952S stepper motor controller is capable of continuous output currents up to 2 A and operating voltages range up to 50 V.

Internal fixed off-time PWM current-c ontrol circuitry can be used to regulate the maximum load current to a desired value. The MODE terminal can be used to optimize the performance of the device in microstepping / sinusoidal stepper motor drive applications. When the average load current is increasing, slow-decay mode is used to limit the switching losses in the device and iron losses in the motor.

The thermal performance in applications with high load currents and/or high duty cycles can be improved by adding external diodes in parallel with the internal diodes. In internal PWM slow-decay applications, only the two top-side (flyback) diodes need be added. For internal fast-decay PWM, or external PHASE or ENABLE input PWM applications, all four external diodes should be added for maximum junction temperature reduction.

We aim to transmit more information by carrying articles. Please send us an E-mail to wanghuali@hqew. net within 15 days if we are involved in the problems of article content, copyright or other problems. We will delete it soon. 🔗 External reference

The A3952S stepper motor controller is an integrated circuit designed to drive stepper motors efficiently and effectively. This device is particularly advantageous for applications requiring precise control of motor position and speed. The controller's ability to handle continuous output currents of up to 2 A makes it suitable for a variety of stepper motors, from small to medium-sized applications.

The internal fixed off-time PWM current control circuitry is a key feature, as it allows the user to set a maximum load current, which is crucial for protecting the motor and the driver from overheating and damage. The use of the MODE terminal provides flexibility in operation, enabling the selection of different modes for microstepping, which enhances the smoothness of motor operation and reduces vibrations.

In applications where the load current is subject to rapid changes, the implementation of slow-decay mode is beneficial. This mode helps in reducing the switching losses that occur during the operation of the motor, thereby improving overall efficiency. Additionally, the reduction of iron losses in the motor contributes to better performance and longevity of the motor.

For applications that demand high performance under heavy loads or continuous duty cycles, the thermal management of the A3952S is critical. By adding external diodes in parallel with the internal diodes, heat dissipation can be significantly improved. This is particularly important in high-current scenarios where excessive heat can lead to failure of the device. The recommendation to use only the top-side diodes for slow-decay applications simplifies the design while ensuring adequate thermal performance. Conversely, for fast-decay PWM applications, the inclusion of all four external diodes is essential to maintain optimal thermal conditions and prevent junction temperature from exceeding safe limits.

In summary, the A3952S stepper motor controller is a versatile and efficient solution for driving stepper motors in various electronic applications, providing features that enhance performance, efficiency, and thermal management.Using the A3952S stepper motor controller designed by Allegro MicroSystems can be designed a very simple and useful motor driver circuit that can be used in many electronic applications. A3952S stepper motor controller is capable of continuous output currents up to 2 A and operating voltages range up to 50 V.

Internal fixed off-time PWM current-c ontrol circuitry can be used to regulate the maximum load current to a desired value. The MODE terminal can be used to optimize the performance of the device in microstepping / sinusoidal stepper motor drive applications. When the average load current is increasing, slow-decay mode is used to limit the switching losses in the device and iron losses in the motor.

The thermal performance in applications with high load currents and/or high duty cycles can be improved by adding external diodes in parallel with the internal diodes. In internal PWM slow-decay applications, only the two top-side (flyback) diodes need be added. For internal fast-decay PWM, or external PHASE or ENABLE input PWM applications, all four external diodes should be added for maximum junction temperature reduction.

We aim to transmit more information by carrying articles. Please send us an E-mail to wanghuali@hqew. net within 15 days if we are involved in the problems of article content, copyright or other problems. We will delete it soon. 🔗 External reference