Drive an RGB led with software PWM

This project demonstrates the use of an ATTiny microcontroller and an RGB LED to create a light that continuously cycles through random colors, with the ability to change color dramatically at the press of a switch. The inspiration for this project came from a $2 novelty pen that utilized a small circuit along with 3x3mm LEDs and alkaline coin cells. It is important to ensure the LED is safe for children, which can be achieved by selecting a non-superbright LED or using a diffuse LED. Diffusion can be accomplished by covering the LED with half a table tennis ball or encapsulating it in resin or wax. Additionally, using higher-value resistors can limit current, or the PWM_OC_MAX value can be reduced to limit the PWM duty cycle via software. The microcontroller should be configured to use the 8MHz internal RC oscillator for the system clock. The factory fuse settings of the ATTiny13 divide the RC oscillator frequency to 1MHz, so it is necessary to change this fuse to restore the 8MHz signal. An overflow interrupt from the hardware 8-bit timer triggers an interrupt service routine approximately 32,000 times per second, incrementing three separate 8-bit counters. These counters, along with corresponding Output Compare (OC) values, generate three Pulse-Width-Modulated (PWM) waveforms, each associated with a specific output pin. When a counter reaches zero, the corresponding pin is activated, and when it reaches its PWM_OC value, the pin is deactivated. The counter wraps around to zero upon reaching its PWM_TOP value (255), repeating the cycle. As a result, each output pin is driven by a square wave with a wavelength of 256 timer ticks, translating to a frequency of 128Hz. The OC value determines the "duty cycle" of the waveform, where 0 means always off, 255 means always on, and intermediate values indicate varying on and off periods. Human perception of flickering is mitigated at frequencies above approximately 50Hz, allowing changes in duty cycle to be perceived as variations in brightness, similar to household dimmers. By using three LEDs in red, green, and blue, and adjusting the brightness of each, a wide range of colors can be produced, akin to modern televisions and projectors. Although it is possible to use a single counter with different OC values to control each output pin, the implementation of three distinct channels is preferred to reduce peak current draw and extend battery life. For instance, setting PWM_TOP to 240 and PWM_OC_MAX to 80 ensures that the three output pins are never on simultaneously, limiting peak output current to 20mA and allowing the use of a single resistor instead of three. At the end of every PWM cycle, the duty cycle for each channel changes slightly, resulting in a gradual color transition. The rate of change for each PWM channel is determined semi-randomly to create a continuously evolving color display. When the CHANGE button is pressed, the LEDs are reset to off (OCx=0), and the cycle rate of one channel is altered to a new random value, resulting in a sudden shift in color, followed by a new sequence of color changes. This feature is particularly engaging for children, who may repeatedly press the button. Both buttons utilize pin-change interrupts, and software debouncing is implemented by masking further interrupts for a specific interval following any button press. Prototyping was conducted on a solderless breadboard, and the ATTiny was programmed using an AVRUSB500v2 programmer, which allows for in-circuit programming via a 1x5 connector. A simple voltage regulator can be employed, although it is not mandatory. The ATTiny chips are available in a 5V version capable of operating at 20MHz, as well as a low-voltage version that functions at voltages as low as 1.8V (limited to 4 or 10MHz). An LP2950 low-dropout regulator was utilized to provide 5V from four alkaline cells or 3.3V from three cells. A 9V battery can also be used with a common 78L05 regulator, which requires a minimum input of 7V. Alternatively, the regulator can be omitted if a 4.5V alkaline pack or a 3.7V lithium battery is employed. The low-voltage ATTiny13v is tolerant of varying conditions, but it is essential to set the brown-out fuses to an appropriate low-voltage cutoff. A PCB design has not yet been created, as it would not significantly reduce the size compared to the protoboard version. However, a surface-mount design could be developed to create a compact module comparable in size to the coin cells used for power, presenting potential safety concerns.

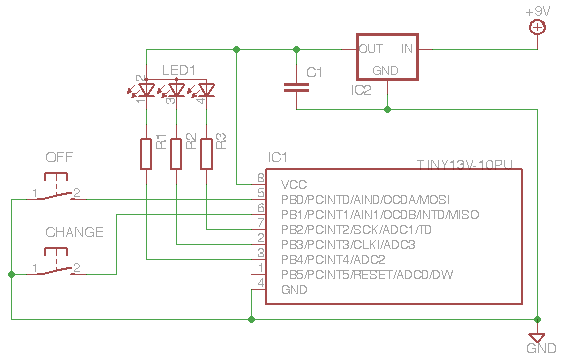

The electronic schematic for this project involves the integration of an ATTiny microcontroller, RGB LEDs, and a push-button switch. The ATTiny microcontroller is configured to utilize an 8MHz clock signal from the internal RC oscillator, with appropriate fuse settings adjusted to ensure optimal performance. The microcontroller's output pins are connected to the RGB LED, allowing for independent control of each color channel through PWM. Each channel is driven by a dedicated 8-bit counter, which is incremented by an overflow interrupt from the hardware timer. The PWM duty cycle for each channel is adjusted periodically to create a smooth transition of colors.

The button switch is connected to an interrupt pin on the microcontroller, enabling immediate response to user input. Software debouncing is implemented to ensure reliable button presses. The circuit may include current-limiting resistors for the LED channels to prevent excessive current flow, enhancing safety and prolonging component life.

Power supply options include the use of alkaline batteries or lithium cells, with a voltage regulator employed as necessary to maintain a stable operating voltage for the ATTiny microcontroller. The entire circuit can be prototyped on a breadboard for initial testing, with the possibility of developing a compact PCB layout in the future. This project exemplifies the application of microcontroller technology in creating interactive and visually engaging electronic displays.This project illustrates how to use an ATTiny microcontroller and an RGB LED to create a coloured light that cyles continuously through random colours, but changes colour dramatically at the press of a switch. Why My kids had this $2 novelty pen that did this employing a teensy circuit along with 3x3mm LEDs and some alkaline coin-cells.

If children will play with this, choose one of the following: ensure your LED is not a superbright, or use a diffuse led, or diffuse a clear one (eg cover it with half a table tennis ball, or enclose it in resin or wax. You could also use higher-value resistors to limit current, or lower PWM_OC_MAX to limit the PWM duty-cycle (LED brightness) via software.

The microcontroller should be configured to obtain the system clock from the 8MHz internal RC oscillator. The ATTiny13 factory fuse settings include a divide-by-8 of the RC oscillator giving 1MHz, so remember to change that fuse to get the original 8MHz signal.

The overflow interrupt from the hardware 8-bit timer triggers an interrupt service routine (roughly 32000 times per second) which increments each of 3 separate 8 bit counters. These counters, and corresponding "Output Compare" (OC) values are used to generate 3 Pulse-Width-Modulated waveforms, with each counter being associated with a particular output pin.

Every time a counter reaches zero, the corresponding pin is turned on. When the counter reaches its PWM_OC value it is turned off. When the counter reaches its PWM_TOP value (255) it wraps around to zero and the cycle repeats. The effect of all this is that each of the 3 output pins is driven with a square-wave having a wave-legnth of 256 timer ticks (about 1/128 of a second), which is equivalent to a frequency of 128Hz (cycles-per-second). The OC value controls the "duty-cycle" (ratio of on-period to off-period) of the wave, with 0 giving always off, 255 always on, and any intermediate value giving a wave that is on for x/255 of a cycle and off for the remainder of each cycle.

If an electric light is powered by such a square wave, with a frequency of more than about 50Hz, the human eye does not percieve any flickering-instead changes in the duty cycle are perceived as changes in brightness (this is how most household dimmers work). With 3 leds in Red, Green and Blue, and the ability to vary the perceived brighness of each, you can produce many different colours, exactly as is done in modern TVs and projectors.

So using 3 PWM outputs, we have a coloured light that we can set to any brightness and colour (denoted by a particular [R=x, G=y, B=z] tuple) that we desire. BTW, it`s not strictly necessary to use 3 separate counters. A single counter could be used with 3 different OC values to control each output pin independently. I chose to implement 3 distinct channels (rather than 1 channel with 3 Output-compare values) out of some voodoo idea that running the channels out-of-phase will lower the peak current draw and give slightly longer battery life.

For example, if you set PWM_TOP to 240 and PWM_OC_MAX to 80, then if the PWM counters are initialized at 0, 80 and 160, the 3 output pins will never be on simultaneously, and peak output current will never be more than 20mA. This also means you can get away with ONE resistor instead of 3. For each of the 3 channels, at the end of every PWM cycle (when the counter reaches 255), the duty cycle of the particular channel changes by a small amount.

This causes the colour to change. The rate that each of the PWM channels changes duty-cycle is chosen semi-randomly such that an ever changing progression of colour is produced. If the CHANGE button is pressed, the LEDs are reset to all off (OCx=0), and the cycle-rate of one channel is changed to a new random value, giving an abrupt change of colour, followed by a new and different progression of colour changes.

Small children love this and will sit and frob the button for ages, before they break it or lose it. Then you can make them something else. Both buttons trigger interrupts via the pin-change interrupt facility. The buttons are "debounced" in software, by masking further interrupts for a certain interval after any button interrupt. I prototyped this on a solderless breadboard, and programmed the ATTiny with an AVRUSB500v2 programmer, which has the useful advantage of using a 1x5 connector instead of the more common 2x3 or 2x5, allowing simple in-circuit programming of breadboarded AVRs.

You can use any simple voltage regulator (or none). The ATTiny chips come in a 5v version that runs to 20MHz, or a low voltage version that will work off as low as 1. 8v (but is limited to 4 or 10MHz). I used an LP2950 low-dropout regulator, which will easily give you 5v from 4 alkaline cells, or 3. 3v from 3 cells. If you`re using a 9v battery, the cheap and common 78L05 (which needs an input of at least 7 volts) works fine too.

You could even leave the regulator off entirely, if you use a 4. 5v alkaline pack or a 3. 7v lithium. The low-votage ATTiny13v is remarkably forgiving (but remember to set the brown-out fuses to an appropriate low-voltage cutoff). I haven`t bothered to design a PCB yet, as it wouldn`t be significantly more compact than the protoboard version.

I suppose an SMD version would be interesting-it could be made not much larger than the coin cells that power it, giving some interesting swallowing-hazard fun to be had. 🔗 External reference

The electronic schematic for this project involves the integration of an ATTiny microcontroller, RGB LEDs, and a push-button switch. The ATTiny microcontroller is configured to utilize an 8MHz clock signal from the internal RC oscillator, with appropriate fuse settings adjusted to ensure optimal performance. The microcontroller's output pins are connected to the RGB LED, allowing for independent control of each color channel through PWM. Each channel is driven by a dedicated 8-bit counter, which is incremented by an overflow interrupt from the hardware timer. The PWM duty cycle for each channel is adjusted periodically to create a smooth transition of colors.

The button switch is connected to an interrupt pin on the microcontroller, enabling immediate response to user input. Software debouncing is implemented to ensure reliable button presses. The circuit may include current-limiting resistors for the LED channels to prevent excessive current flow, enhancing safety and prolonging component life.

Power supply options include the use of alkaline batteries or lithium cells, with a voltage regulator employed as necessary to maintain a stable operating voltage for the ATTiny microcontroller. The entire circuit can be prototyped on a breadboard for initial testing, with the possibility of developing a compact PCB layout in the future. This project exemplifies the application of microcontroller technology in creating interactive and visually engaging electronic displays.This project illustrates how to use an ATTiny microcontroller and an RGB LED to create a coloured light that cyles continuously through random colours, but changes colour dramatically at the press of a switch. Why My kids had this $2 novelty pen that did this employing a teensy circuit along with 3x3mm LEDs and some alkaline coin-cells.

If children will play with this, choose one of the following: ensure your LED is not a superbright, or use a diffuse led, or diffuse a clear one (eg cover it with half a table tennis ball, or enclose it in resin or wax. You could also use higher-value resistors to limit current, or lower PWM_OC_MAX to limit the PWM duty-cycle (LED brightness) via software.

The microcontroller should be configured to obtain the system clock from the 8MHz internal RC oscillator. The ATTiny13 factory fuse settings include a divide-by-8 of the RC oscillator giving 1MHz, so remember to change that fuse to get the original 8MHz signal.

The overflow interrupt from the hardware 8-bit timer triggers an interrupt service routine (roughly 32000 times per second) which increments each of 3 separate 8 bit counters. These counters, and corresponding "Output Compare" (OC) values are used to generate 3 Pulse-Width-Modulated waveforms, with each counter being associated with a particular output pin.

Every time a counter reaches zero, the corresponding pin is turned on. When the counter reaches its PWM_OC value it is turned off. When the counter reaches its PWM_TOP value (255) it wraps around to zero and the cycle repeats. The effect of all this is that each of the 3 output pins is driven with a square-wave having a wave-legnth of 256 timer ticks (about 1/128 of a second), which is equivalent to a frequency of 128Hz (cycles-per-second). The OC value controls the "duty-cycle" (ratio of on-period to off-period) of the wave, with 0 giving always off, 255 always on, and any intermediate value giving a wave that is on for x/255 of a cycle and off for the remainder of each cycle.

If an electric light is powered by such a square wave, with a frequency of more than about 50Hz, the human eye does not percieve any flickering-instead changes in the duty cycle are perceived as changes in brightness (this is how most household dimmers work). With 3 leds in Red, Green and Blue, and the ability to vary the perceived brighness of each, you can produce many different colours, exactly as is done in modern TVs and projectors.

So using 3 PWM outputs, we have a coloured light that we can set to any brightness and colour (denoted by a particular [R=x, G=y, B=z] tuple) that we desire. BTW, it`s not strictly necessary to use 3 separate counters. A single counter could be used with 3 different OC values to control each output pin independently. I chose to implement 3 distinct channels (rather than 1 channel with 3 Output-compare values) out of some voodoo idea that running the channels out-of-phase will lower the peak current draw and give slightly longer battery life.

For example, if you set PWM_TOP to 240 and PWM_OC_MAX to 80, then if the PWM counters are initialized at 0, 80 and 160, the 3 output pins will never be on simultaneously, and peak output current will never be more than 20mA. This also means you can get away with ONE resistor instead of 3. For each of the 3 channels, at the end of every PWM cycle (when the counter reaches 255), the duty cycle of the particular channel changes by a small amount.

This causes the colour to change. The rate that each of the PWM channels changes duty-cycle is chosen semi-randomly such that an ever changing progression of colour is produced. If the CHANGE button is pressed, the LEDs are reset to all off (OCx=0), and the cycle-rate of one channel is changed to a new random value, giving an abrupt change of colour, followed by a new and different progression of colour changes.

Small children love this and will sit and frob the button for ages, before they break it or lose it. Then you can make them something else. Both buttons trigger interrupts via the pin-change interrupt facility. The buttons are "debounced" in software, by masking further interrupts for a certain interval after any button interrupt. I prototyped this on a solderless breadboard, and programmed the ATTiny with an AVRUSB500v2 programmer, which has the useful advantage of using a 1x5 connector instead of the more common 2x3 or 2x5, allowing simple in-circuit programming of breadboarded AVRs.

You can use any simple voltage regulator (or none). The ATTiny chips come in a 5v version that runs to 20MHz, or a low voltage version that will work off as low as 1. 8v (but is limited to 4 or 10MHz). I used an LP2950 low-dropout regulator, which will easily give you 5v from 4 alkaline cells, or 3. 3v from 3 cells. If you`re using a 9v battery, the cheap and common 78L05 (which needs an input of at least 7 volts) works fine too.

You could even leave the regulator off entirely, if you use a 4. 5v alkaline pack or a 3. 7v lithium. The low-votage ATTiny13v is remarkably forgiving (but remember to set the brown-out fuses to an appropriate low-voltage cutoff). I haven`t bothered to design a PCB yet, as it wouldn`t be significantly more compact than the protoboard version.

I suppose an SMD version would be interesting-it could be made not much larger than the coin cells that power it, giving some interesting swallowing-hazard fun to be had. 🔗 External reference