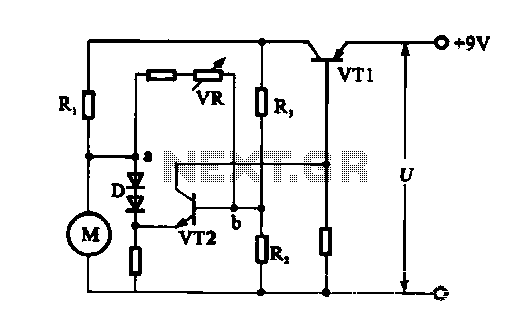

Electronic circuit steady speed motor application

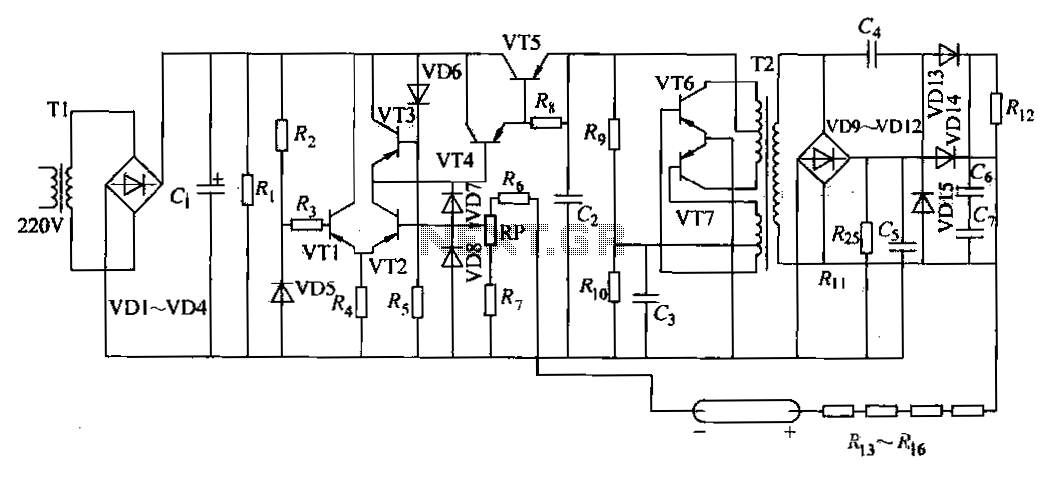

The electronic circuit for steady speed motor applications utilizes an automatic remote control system to regulate the motor power supply, thereby achieving consistent speed control. The circuit diagram illustrates a DC motor connected to the system. Given that the DC motor has coil winding impedance, a new circuit design is implemented. Resistors R1, R2, and R3 are selected to maintain equilibrium in the system. As the rotor rotates, it generates counter electromotive force (back EMF), which influences the motor's speed in relation to the resistance. The potential difference between points A and B is directly proportional to the motor speed. As the motor speed increases, the back EMF rises, resulting in a higher potential at point B compared to point A. Consequently, the emitter voltage of transistor VT2 increases, leading to a decrease in the base current of VT2, which in turn reduces the collector current. The collector current of VT2 also affects the base current of transistor VT1, further decreasing its collector current. This cascade of effects results in a drop in the power supply voltage to the motor, thereby automatically reducing the motor speed.

The electronic circuit designed for steady speed motor applications functions by integrating an automatic remote control mechanism that regulates the power supply to the motor. This system is particularly beneficial for applications requiring consistent motor speeds, such as conveyor belts, fans, or automated machinery.

In the circuit, the DC motor is connected to a series of resistors (R1, R2, and R3) which are strategically chosen based on the impedance of the motor's coil winding. The relationship between the resistors is critical for achieving a state of equilibrium, ensuring stable operation. The motor generates a back EMF during its rotation, which counteracts the applied voltage. This back EMF is proportional to the speed of the motor; as the speed increases, so does the back EMF, thereby affecting the potential difference across points A and B in the circuit.

Transistor VT2 plays a pivotal role in controlling the motor speed. As the back EMF increases with higher motor speeds, the potential at point B rises, which causes the emitter voltage of VT2 to increase. This change results in a reduction of the base current flowing into VT2, leading to a decrease in the collector current. The collector current from VT2 is also linked to the base current of VT1, which further reduces VT1's collector current. This cascading effect ultimately results in a decrease in the voltage supplied to the motor, thereby reducing its speed in a controlled manner.

The design ensures that the motor operates within a predefined speed range, enhancing efficiency and prolonging the lifespan of the motor by preventing excessive speeds that could lead to mechanical failure. The circuit's automatic feedback mechanism allows for real-time adjustments, making it suitable for various applications where precision in motor speed is essential.Electronic circuit steady speed motor applications Electronic steady speed mode is automatic remote control over the role of the motor power supply circuit to the motor to achi eve steady speed control, shown is an application circuit. Figure (b), visible, DC motor connected to the circuit, as part of the circuit. Since the DC motor line has a coil winding impedance, then into the new circuit. So choose resistors RI, Rz, R3, so rIJRI R: Z/R3, state of equilibrium. Because during the rotation of the rotor coil generates counter electromotive force, and the role of the electromotive force of the motor causes the motor speed changes with the resistance rm, so between a, b will produce the motor speed is proportional to the potential difference. That is, when the motor speed increases, back electromotive force becomes large, a relative point b point potential becomes high.

VT2 of the transistor emitter voltage is raised, VT2 base current decreases, VI2 collector current also decreases. VT2 VT1 collector current is the base current of the transistor, which would also make the collector current decreases VT1.

Thus, for the motor power supply voltage drop, the motor speed is automatically reduced.

The electronic circuit designed for steady speed motor applications functions by integrating an automatic remote control mechanism that regulates the power supply to the motor. This system is particularly beneficial for applications requiring consistent motor speeds, such as conveyor belts, fans, or automated machinery.

In the circuit, the DC motor is connected to a series of resistors (R1, R2, and R3) which are strategically chosen based on the impedance of the motor's coil winding. The relationship between the resistors is critical for achieving a state of equilibrium, ensuring stable operation. The motor generates a back EMF during its rotation, which counteracts the applied voltage. This back EMF is proportional to the speed of the motor; as the speed increases, so does the back EMF, thereby affecting the potential difference across points A and B in the circuit.

Transistor VT2 plays a pivotal role in controlling the motor speed. As the back EMF increases with higher motor speeds, the potential at point B rises, which causes the emitter voltage of VT2 to increase. This change results in a reduction of the base current flowing into VT2, leading to a decrease in the collector current. The collector current from VT2 is also linked to the base current of VT1, which further reduces VT1's collector current. This cascading effect ultimately results in a decrease in the voltage supplied to the motor, thereby reducing its speed in a controlled manner.

The design ensures that the motor operates within a predefined speed range, enhancing efficiency and prolonging the lifespan of the motor by preventing excessive speeds that could lead to mechanical failure. The circuit's automatic feedback mechanism allows for real-time adjustments, making it suitable for various applications where precision in motor speed is essential.Electronic circuit steady speed motor applications Electronic steady speed mode is automatic remote control over the role of the motor power supply circuit to the motor to achi eve steady speed control, shown is an application circuit. Figure (b), visible, DC motor connected to the circuit, as part of the circuit. Since the DC motor line has a coil winding impedance, then into the new circuit. So choose resistors RI, Rz, R3, so rIJRI R: Z/R3, state of equilibrium. Because during the rotation of the rotor coil generates counter electromotive force, and the role of the electromotive force of the motor causes the motor speed changes with the resistance rm, so between a, b will produce the motor speed is proportional to the potential difference. That is, when the motor speed increases, back electromotive force becomes large, a relative point b point potential becomes high.

VT2 of the transistor emitter voltage is raised, VT2 base current decreases, VI2 collector current also decreases. VT2 VT1 collector current is the base current of the transistor, which would also make the collector current decreases VT1.

Thus, for the motor power supply voltage drop, the motor speed is automatically reduced.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713