Few words about CPLD

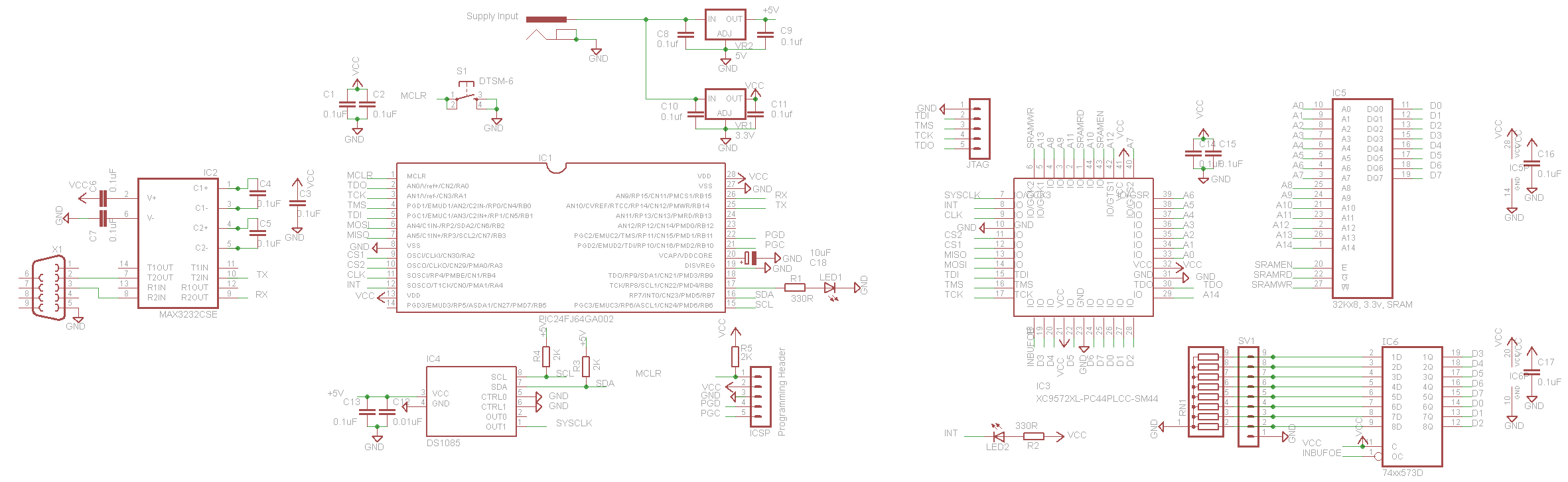

The project involves the use of a Lattice isp2032VE110LT144 programmable logic chip, with a focus on integrating an LCD screen module. The development process included using MS Visual Basic for LCD control and the ispLever Navigator software for programming the CPLD. The chip was soldered onto a custom PCB, and the project was initiated from scratch. The HDL (hardware description language) was not fully utilized; instead, a mixed approach of ABEL and schematic diagrams was employed. The project necessitated the generation of clock, vsync, and hsync pulses for the LCD, with specific modules designed for row and column detection logic. The binary counter was implemented using two different types of counters: a 4-bit counter for dividing the master clock and an 8-bit counter with a reset pin. The ispLever software generated schematic symbols from the scripts, allowing for circuit simulation and testing. The simulation required significant computational resources due to the extensive screen timing requirements. The Constraint Editor was used to connect signals to the chip's pins, and the programming was executed using the LSC ispVM System software with a JTAG cable. The project faced limitations due to the chip's memory capacity, suggesting a potential shift to an FPGA for completion.

The project centers around the implementation of a programmable logic device, specifically the Lattice isp2032VE110LT144 chip, to control an LCD screen module without a microcontroller. The integration process began with the soldering of the chip onto a custom-designed printed circuit board (PCB). The programming environment utilized was ispLever Navigator, which facilitates the development of complex digital systems.

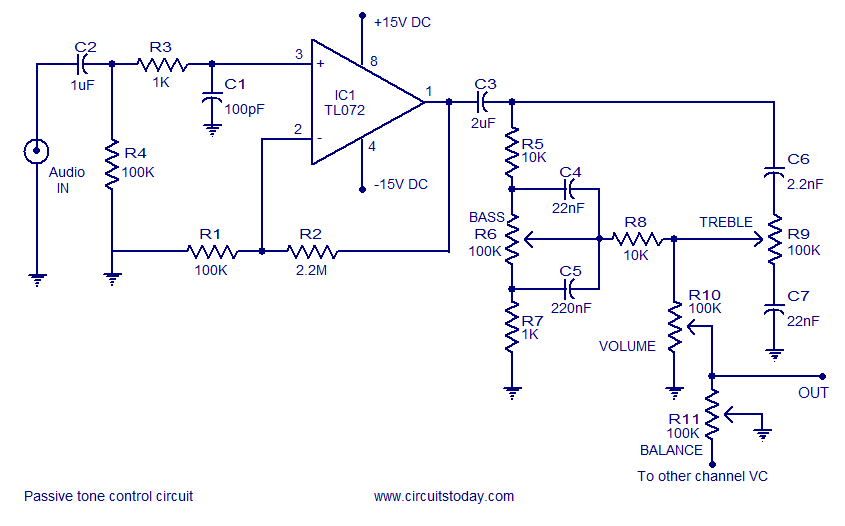

To initiate the project, a mixed design approach was adopted, utilizing both ABEL and schematic representations. This choice allowed for the flexibility of defining certain modules in ABEL, which is a high-level hardware description language, while also leveraging the graphical capabilities of the schematic editor to interconnect the various components. The primary challenge addressed was generating the necessary timing signals for the LCD operation, specifically the clock, vertical sync (vsync), and horizontal sync (hsync) signals.

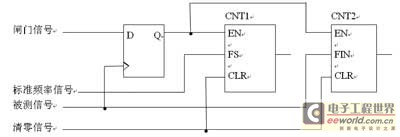

Row and column detection modules were crafted to manage the addressing of the LCD. In the ABEL language, modules are defined with mandatory fields, including the module name, variable declarations, and the logic equations that govern their functionality. The row detection logic was implemented through a specific ABEL file, while the column detection logic mirrored this structure.

A significant aspect of the design involved the use of binary counters. A 4-bit counter was employed to divide the master clock frequency, simplifying the logic from existing examples. In contrast, an 8-bit counter was designed with a reset functionality, adding complexity to the timing control. The ispLever software was instrumental in generating schematic symbols from the ABEL scripts, which could then be integrated into the overall circuit design.

Simulation capabilities provided by the software allowed for extensive testing of the circuit. However, the simulation of the LCD logic required substantial computational power due to the high volume of clock cycles needed to replicate full-screen timings. This necessitated a robust computer system to manage the simulation effectively.

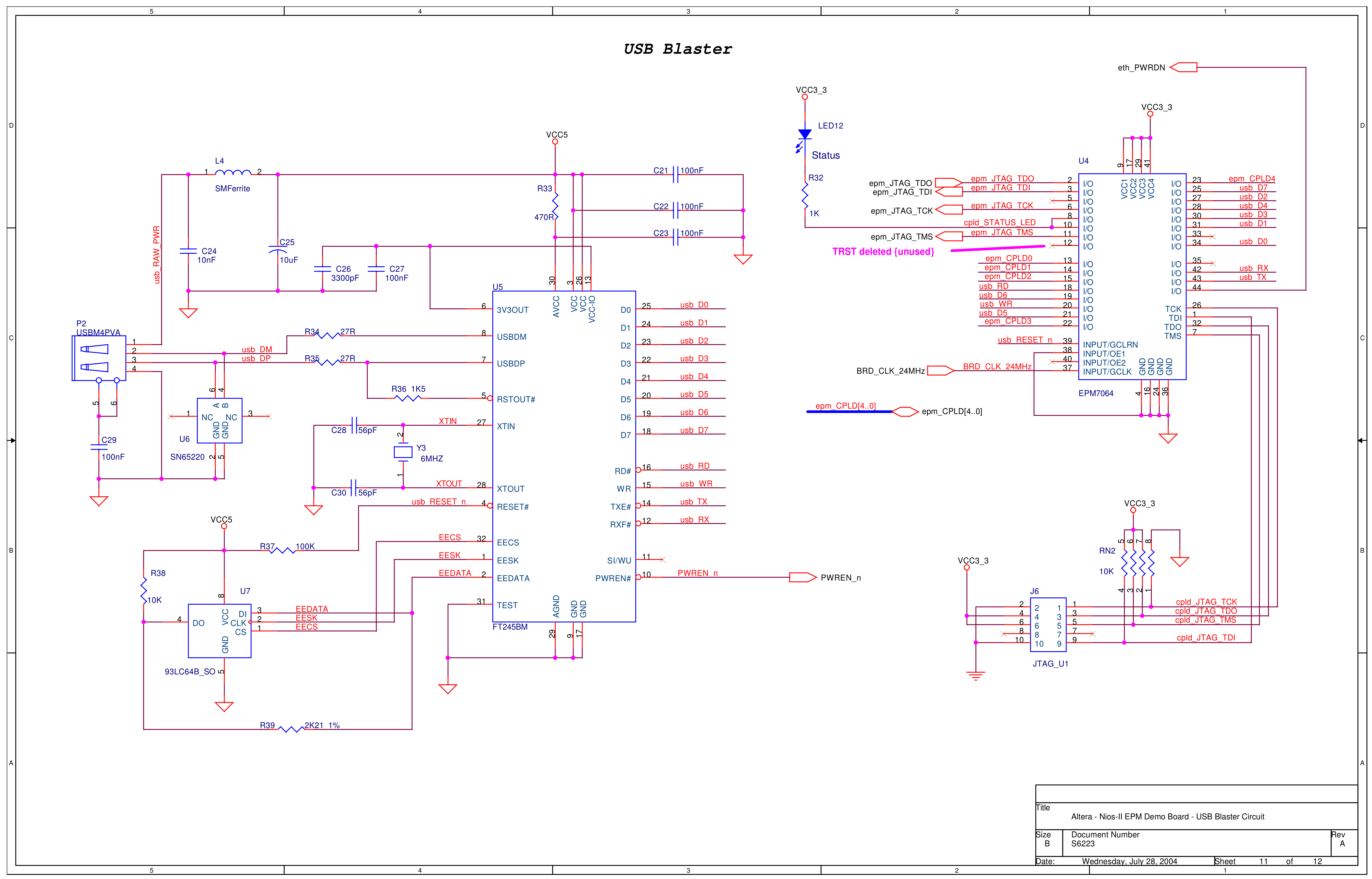

Once the logical design was validated through simulation, the Constraint Editor was utilized to assign the necessary signals to the physical pins of the Lattice chip. Although pin assignments could be described in ABEL, the graphical interface offered a more intuitive method for making adjustments. The final programming of the chip was executed using the LSC ispVM System software via a JTAG interface, enabling real-time testing and modifications.

Despite the progress made, the limitations of the isp2032VE110LT144 chip's memory capacity hindered the project's completion. The potential for future development exists with the transition to a field-programmable gate array (FPGA), which would provide greater resources and flexibility for the project. The current state of the project includes a visual display from the LCD screen, albeit with limitations, indicating the need for further enhancements and optimizations.I forced myself to use and learn about programmable logic chips. As I wrote in my older post, I have very small inventory of the chips and was forced to use Lattice isp2032VE110LT144 chip. I received great help reading article from Seattle Robotics Society web page. Also, at same time I was experimenting with controller-less LCD screen module. So I joined both ideas to one project and here is the result. The theory about LCD control was tested using big computer and MS Visual Basic software. CPLD programing software I downloaded from Lattice Semiconductors site. The chip was soldered to self-made testing PCB. I started ispLever Navigator and started my project from nill. I not too smart to wrote all signals is HDL (hardware description language) so I selected mixed type of the project: ABEL + Schematics. So I can describe some modules in ABEL language and connect all modules using graphics editor in schematics editor.

I selected ABEL as I had some examples already written in it. In theory I need to feed LCD with clock, vsync and hsync pulses. It is very easy to describe column and row detection logic modules. Here is row detector (eiles. abv) In ABLEL language there are few mandatory fields: MODULE name of the module; declarations- declaration of the variables and wires; equations- the logic formulas itself. In this example we use whole bunch of wires or bus called a[] a8, a9, a10 and etc. up to a15. I collected wires to bus for easy description. In equations section we just test the bus for some value. The column detect is identical (stulpai. abv): The binary counter is a bit more complicated. I use two types of counters in this project- one is 4 bit counter for dividing frequency of master clock (count4.

abl): This counter is created using example. I only simplified it. It just divides the master clock. Other counter is more complicated- it has reset pin (count8. abl): IspLever software generate schematic symbols from these scripts and they can be placed into circuit diagram as components. So I added some standard logic and here is the result: It is possible to simulate and test the circuit just using software in your computer.

There is special software for this and you can watch all oscillograms on the screen. The problem is, that to test all LCD logic the computer must simulated whole screen timings- tens of thousands of clock tics. It took lots of memory and time in computer. You must have quick one. Now we can star Constraint Editor and connect all signals to real pins of the chip. It is possible to describe pins in ABEL language, but is much easier to do it in graphic interface. And it much more easier to change the pins in visual way. Now start LSC ispVM System program and program real chip using JTAG cable. And now time for experiments and fine tuning of the project- just change, recompile and reprogram the chip.

The chip can be reprogrammed tens of thousands times, so don`t worry. In the image you can see part of the LCD screen with chaotic image. This image is generated from ROM chip- it is used as video RAM . But the project is closed as the chip is too small for this project. Maybe I`ll finish this project using FPGA chip. 🔗 External reference

The project centers around the implementation of a programmable logic device, specifically the Lattice isp2032VE110LT144 chip, to control an LCD screen module without a microcontroller. The integration process began with the soldering of the chip onto a custom-designed printed circuit board (PCB). The programming environment utilized was ispLever Navigator, which facilitates the development of complex digital systems.

To initiate the project, a mixed design approach was adopted, utilizing both ABEL and schematic representations. This choice allowed for the flexibility of defining certain modules in ABEL, which is a high-level hardware description language, while also leveraging the graphical capabilities of the schematic editor to interconnect the various components. The primary challenge addressed was generating the necessary timing signals for the LCD operation, specifically the clock, vertical sync (vsync), and horizontal sync (hsync) signals.

Row and column detection modules were crafted to manage the addressing of the LCD. In the ABEL language, modules are defined with mandatory fields, including the module name, variable declarations, and the logic equations that govern their functionality. The row detection logic was implemented through a specific ABEL file, while the column detection logic mirrored this structure.

A significant aspect of the design involved the use of binary counters. A 4-bit counter was employed to divide the master clock frequency, simplifying the logic from existing examples. In contrast, an 8-bit counter was designed with a reset functionality, adding complexity to the timing control. The ispLever software was instrumental in generating schematic symbols from the ABEL scripts, which could then be integrated into the overall circuit design.

Simulation capabilities provided by the software allowed for extensive testing of the circuit. However, the simulation of the LCD logic required substantial computational power due to the high volume of clock cycles needed to replicate full-screen timings. This necessitated a robust computer system to manage the simulation effectively.

Once the logical design was validated through simulation, the Constraint Editor was utilized to assign the necessary signals to the physical pins of the Lattice chip. Although pin assignments could be described in ABEL, the graphical interface offered a more intuitive method for making adjustments. The final programming of the chip was executed using the LSC ispVM System software via a JTAG interface, enabling real-time testing and modifications.

Despite the progress made, the limitations of the isp2032VE110LT144 chip's memory capacity hindered the project's completion. The potential for future development exists with the transition to a field-programmable gate array (FPGA), which would provide greater resources and flexibility for the project. The current state of the project includes a visual display from the LCD screen, albeit with limitations, indicating the need for further enhancements and optimizations.I forced myself to use and learn about programmable logic chips. As I wrote in my older post, I have very small inventory of the chips and was forced to use Lattice isp2032VE110LT144 chip. I received great help reading article from Seattle Robotics Society web page. Also, at same time I was experimenting with controller-less LCD screen module. So I joined both ideas to one project and here is the result. The theory about LCD control was tested using big computer and MS Visual Basic software. CPLD programing software I downloaded from Lattice Semiconductors site. The chip was soldered to self-made testing PCB. I started ispLever Navigator and started my project from nill. I not too smart to wrote all signals is HDL (hardware description language) so I selected mixed type of the project: ABEL + Schematics. So I can describe some modules in ABEL language and connect all modules using graphics editor in schematics editor.

I selected ABEL as I had some examples already written in it. In theory I need to feed LCD with clock, vsync and hsync pulses. It is very easy to describe column and row detection logic modules. Here is row detector (eiles. abv) In ABLEL language there are few mandatory fields: MODULE name of the module; declarations- declaration of the variables and wires; equations- the logic formulas itself. In this example we use whole bunch of wires or bus called a[] a8, a9, a10 and etc. up to a15. I collected wires to bus for easy description. In equations section we just test the bus for some value. The column detect is identical (stulpai. abv): The binary counter is a bit more complicated. I use two types of counters in this project- one is 4 bit counter for dividing frequency of master clock (count4.

abl): This counter is created using example. I only simplified it. It just divides the master clock. Other counter is more complicated- it has reset pin (count8. abl): IspLever software generate schematic symbols from these scripts and they can be placed into circuit diagram as components. So I added some standard logic and here is the result: It is possible to simulate and test the circuit just using software in your computer.

There is special software for this and you can watch all oscillograms on the screen. The problem is, that to test all LCD logic the computer must simulated whole screen timings- tens of thousands of clock tics. It took lots of memory and time in computer. You must have quick one. Now we can star Constraint Editor and connect all signals to real pins of the chip. It is possible to describe pins in ABEL language, but is much easier to do it in graphic interface. And it much more easier to change the pins in visual way. Now start LSC ispVM System program and program real chip using JTAG cable. And now time for experiments and fine tuning of the project- just change, recompile and reprogram the chip.

The chip can be reprogrammed tens of thousands times, so don`t worry. In the image you can see part of the LCD screen with chaotic image. This image is generated from ROM chip- it is used as video RAM . But the project is closed as the chip is too small for this project. Maybe I`ll finish this project using FPGA chip. 🔗 External reference