Flyback Transformer Driver Circuit

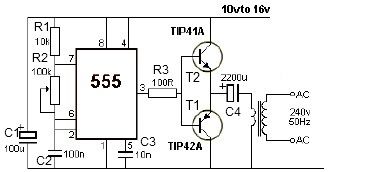

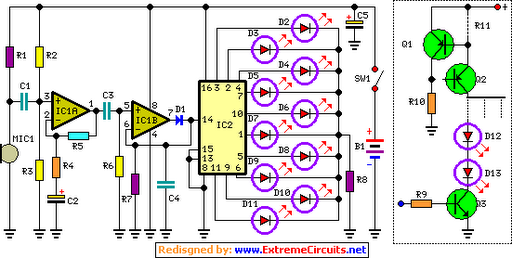

Many sites do not provide circuits for driving these transformers; they simply state that they are ineffective. However, this assertion is contested. A circuit has been developed that operates effectively, with significant effort invested in determining the resonant frequency (approximately 15 kHz) and duty cycle. These transformers perform optimally at around 90% duty cycle. It is possible to observe corona breakdown at the terminals along with a hissing sound and ozone smell when adjusting the off-time trimmer to values near 500-300 ohms. The circuit is versatile and can be adapted for various types of flyback transformers, as frequency and duty cycle can vary widely. The frequency range can be expanded using a multi-position switch to select different values for capacitor C3; for instance, using a 2 nF capacitor can achieve frequencies between 80 kHz and 200 kHz. However, flyback transformers with such high resonant frequencies are not commonly found. Additionally, using higher values for C3, such as 200 nF or 2 µF, will lower the frequency, allowing for the use of ignition coils and rectified power transformers at 50 Hz to charge high-voltage electrolytic capacitors at 300-400 V. Unfortunately, the ignition coil used in this application failed due to insulation breakdown from prolonged arc durations. The circuit employs a 555 timer configured in astable mode, with the capacitor charged through a 4.7 kΩ trimmer (noting the presence of a diode) and discharged through a 2.2 kΩ trimmer, allowing for full adjustability of the duty cycle. The resulting square wave is fed into a totem pole configuration consisting of a 2N3904 and a 2N3906 transistor pair, which are cost-effective and readily available. This totem pole arrangement ensures rapid charging and discharging of the gate (approximately 50 ns). The IRF840 MOSFET, which is affordable (approximately 4 euros), is a reliable and powerful choice, capable of handling 8 A continuously and 32 A in pulse conditions, with a drain-source voltage rating of 800 V and an internal zener diode for protection. A snubbing network is included to minimize voltage spikes, protecting both the transistors and the 555 timer IC, with a 100 Ω resistor serving as a compromise between decay time and voltage spike suppression.

The circuit described is a high-frequency switching power supply designed for driving flyback transformers. The use of the 555 timer in astable mode allows for precise control over the frequency and duty cycle, which are critical parameters for efficient transformer operation. The careful selection of components, including the 2N3904 and 2N3906 transistors, provides a robust output stage capable of fast switching, essential for minimizing power losses and maximizing energy transfer to the transformer.

The snubber circuit is an important addition, as it mitigates voltage spikes that can occur during the switching process, which could otherwise damage sensitive components. The choice of the IRF840 MOSFET is particularly suitable due to its high voltage and current ratings, making it capable of handling the demands of the circuit while ensuring reliability under varying load conditions.

Adjustments to the circuit can be made by changing the values of the timing resistors and capacitors, allowing for flexibility in application, whether for high-frequency operations or lower frequency applications where larger capacitors are utilized. The design can accommodate various transformer types, making it a versatile solution for high-voltage applications, including the charging of capacitors and other devices requiring high voltage supply. Proper thermal management and component ratings should be considered to ensure long-term reliability and performance of the circuit. Many sites doesn`t provide circuits driving these transformers, they simply say that they are bad. I don`t agree. In fact I built this circuit. I spent a lot of time for finding resonant frequency (around 15Khz) and duty cycle. These transformers best work at around 90% duty cycle. You may notice corona breakdown at terminals and pfffff sound (as well as the ozone smell) when adjusting the off time trimmer to near 500-300 ohms. Of course it will work for other tipes of flyback as frequency and duty cycle have a large range. Frequency range can be increased using multiposition switch for other values of C3 capacitor, for example 2 nF for 80KHz-200000KHz, but didn`t found flybacks with so high resonant frequencies, in addition with higher values of c3, eg 200nF, 2uF the frequency will drop making possible the use of ignition coils, and rectified power transformers @50Hz to charge high voltage electrolitic caps at 300-400V).

Unfortunately my ignition coil died because insulation breakdown (too long drawn arcs). The 555 is wired as an astable and the capacitor is charged only through the 4, 7Kohm trimmer (notice the diode) and discharged only through the 2. 2 Kohm trimmer, making the duty cycle full adjustable. The square wave is then feed in a totem pole made up of a 2N3904 and a 2N3906, which are cheap, and easy to find.

The totem pole ensures the gate being charged and discharged very fast (approx 50nS i think). The IRF840 is a cheap (i found it for 4euros) reliable and powerful power mosfet, it has current capability of 8 A continuous and 32A pulse, 800V drain source voltage, protecting internal zener diode. There is a snubbing network to ensure that voltage spikes are kept low (unless the insulation of the transformer start to leak) protecting both transistors and 555 IC.

100 ohm is a compromise between decay time and voltage spike. 🔗 External reference

The circuit described is a high-frequency switching power supply designed for driving flyback transformers. The use of the 555 timer in astable mode allows for precise control over the frequency and duty cycle, which are critical parameters for efficient transformer operation. The careful selection of components, including the 2N3904 and 2N3906 transistors, provides a robust output stage capable of fast switching, essential for minimizing power losses and maximizing energy transfer to the transformer.

The snubber circuit is an important addition, as it mitigates voltage spikes that can occur during the switching process, which could otherwise damage sensitive components. The choice of the IRF840 MOSFET is particularly suitable due to its high voltage and current ratings, making it capable of handling the demands of the circuit while ensuring reliability under varying load conditions.

Adjustments to the circuit can be made by changing the values of the timing resistors and capacitors, allowing for flexibility in application, whether for high-frequency operations or lower frequency applications where larger capacitors are utilized. The design can accommodate various transformer types, making it a versatile solution for high-voltage applications, including the charging of capacitors and other devices requiring high voltage supply. Proper thermal management and component ratings should be considered to ensure long-term reliability and performance of the circuit. Many sites doesn`t provide circuits driving these transformers, they simply say that they are bad. I don`t agree. In fact I built this circuit. I spent a lot of time for finding resonant frequency (around 15Khz) and duty cycle. These transformers best work at around 90% duty cycle. You may notice corona breakdown at terminals and pfffff sound (as well as the ozone smell) when adjusting the off time trimmer to near 500-300 ohms. Of course it will work for other tipes of flyback as frequency and duty cycle have a large range. Frequency range can be increased using multiposition switch for other values of C3 capacitor, for example 2 nF for 80KHz-200000KHz, but didn`t found flybacks with so high resonant frequencies, in addition with higher values of c3, eg 200nF, 2uF the frequency will drop making possible the use of ignition coils, and rectified power transformers @50Hz to charge high voltage electrolitic caps at 300-400V).

Unfortunately my ignition coil died because insulation breakdown (too long drawn arcs). The 555 is wired as an astable and the capacitor is charged only through the 4, 7Kohm trimmer (notice the diode) and discharged only through the 2. 2 Kohm trimmer, making the duty cycle full adjustable. The square wave is then feed in a totem pole made up of a 2N3904 and a 2N3906, which are cheap, and easy to find.

The totem pole ensures the gate being charged and discharged very fast (approx 50nS i think). The IRF840 is a cheap (i found it for 4euros) reliable and powerful power mosfet, it has current capability of 8 A continuous and 32A pulse, 800V drain source voltage, protecting internal zener diode. There is a snubbing network to ensure that voltage spikes are kept low (unless the insulation of the transformer start to leak) protecting both transistors and 555 IC.

100 ohm is a compromise between decay time and voltage spike. 🔗 External reference