Fog Lamp Switch Circuit

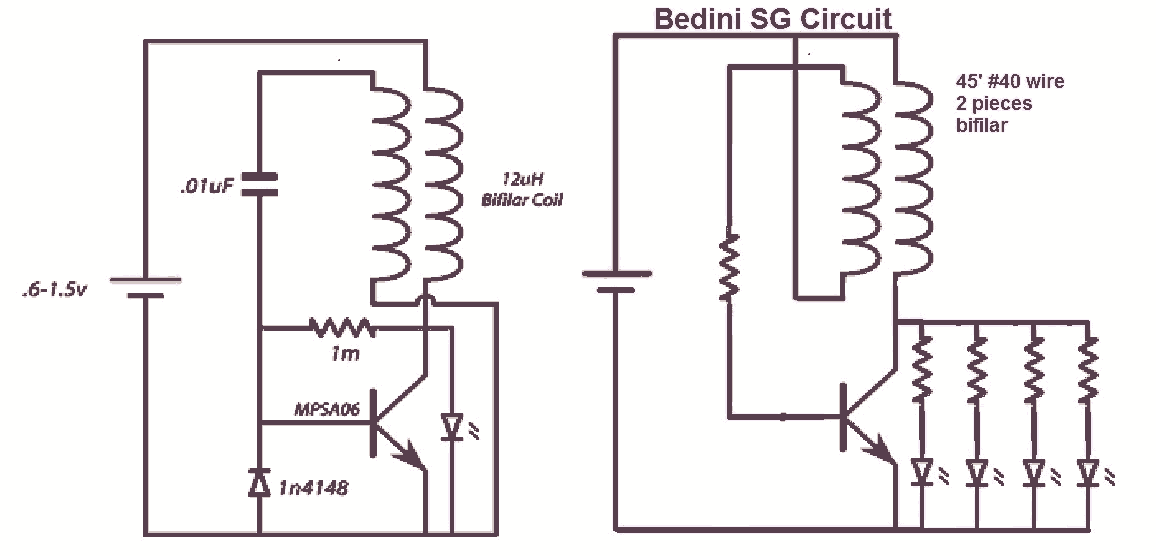

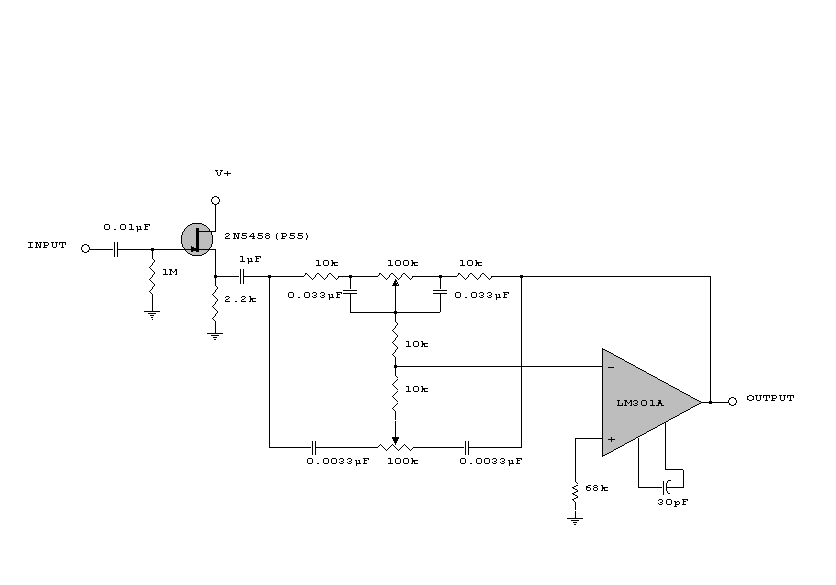

In many countries, it is now mandatory or at least recommended to have a rear fog light on a trailer, with the additional requirement that when the trailer is attached to the vehicle, the rear fog light of the towing vehicle must be turned off. The circuit described here is particularly suitable for this application. The circuit is located near the rear fog light of the vehicle. The 12-volt connection to the lamp is interrupted and instead connected to relay contacts 30 and 87A (K1, K3). When the rear fog light is activated, it continues to function normally. However, if a trailer equipped with a fog light is connected to the trailer connector (either a 7-way or 13-way connector, K2), current will flow through coil L1. L1 consists of approximately eight turns wound around reed contact S1. The current through L1 causes S1 to close, which subsequently energizes relay Re1, turning off the rear fog light of the vehicle while the fog light of the trailer remains illuminated. The size of L1 is determined by the specifications of reed contact S1. Given that the fog lamp consumes 21 watts at 12 volts, the current is approximately 1.75 A. L1 is designed to handle currents between 1.0 and 1.5 A to ensure reliable closure of the contact. The wire gauge should be approximately 0.8 mm. Relay Re1 is an automotive relay capable of switching the lamp current, and the voltage drop across L1 is negligible.

This circuit design effectively addresses the need for compliance with regulations regarding trailer fog lights while ensuring functionality and safety. The use of a relay allows for the automatic disconnection of the vehicle's rear fog light when a trailer is connected, preventing confusion and enhancing visibility for other drivers. The inclusion of a reed contact as a sensing element provides a reliable means of detecting the presence of the trailer. The specifications for the coil L1 are critical; it must be optimized to ensure that the relay is activated promptly without unnecessary power draw or overheating.

In practical implementation, the circuit should be housed in a durable enclosure to protect against environmental factors such as moisture and vibration, which are common in automotive applications. Proper insulation and strain relief should be considered for all connections to maintain circuit integrity over time. Additionally, the selection of high-quality components, such as the relay and reed switch, will contribute to the longevity and reliability of the system. Testing under various conditions, including different trailer loads and environmental scenarios, is essential to validate the design before deployment. This ensures that the system operates as intended, providing safety and compliance with applicable regulations.In most countries it is now mandatory or at least recommended to have a rear fog light on a trailer with the additional requirement that, when the trailer is coupled to the car, the rear fog light of the towing car has to be off. The circuit shown here is eminently suitable for this application. The circuit is placed near the rear fog light of the car. The 12-V connection to the lamp has to be interrupted and is instead connected to relay contacts 30 and 87A (K1, K3). When the rear fog light is turned on it will continue to operate normally. If a trailer with fog light is now connected to the trailer connector (7- or 13-way, K2), a current will flow through L1.

L1 is a coil with about 8 turns, wound around reed contact S1. S1 will close because of the current through L1, which in turn energizes relay Re1 and the rear fog light of the car is switched off. The fog light of the trailer is on, obviously. The size of L1 depends on reed contact S1. The fog lamp is 21 W, so at 12 V there is a current of 1. 75 A. L1 is sized for a current between 1. 0 and 1. 5 A, so that it is certain that the contact closes. The wire size has to be about 0. 8 mm. The relay Re1 is an automotive relay that is capable of switching the lamp current. The voltage drop across L1 is negligible. 🔗 External reference

This circuit design effectively addresses the need for compliance with regulations regarding trailer fog lights while ensuring functionality and safety. The use of a relay allows for the automatic disconnection of the vehicle's rear fog light when a trailer is connected, preventing confusion and enhancing visibility for other drivers. The inclusion of a reed contact as a sensing element provides a reliable means of detecting the presence of the trailer. The specifications for the coil L1 are critical; it must be optimized to ensure that the relay is activated promptly without unnecessary power draw or overheating.

In practical implementation, the circuit should be housed in a durable enclosure to protect against environmental factors such as moisture and vibration, which are common in automotive applications. Proper insulation and strain relief should be considered for all connections to maintain circuit integrity over time. Additionally, the selection of high-quality components, such as the relay and reed switch, will contribute to the longevity and reliability of the system. Testing under various conditions, including different trailer loads and environmental scenarios, is essential to validate the design before deployment. This ensures that the system operates as intended, providing safety and compliance with applicable regulations.In most countries it is now mandatory or at least recommended to have a rear fog light on a trailer with the additional requirement that, when the trailer is coupled to the car, the rear fog light of the towing car has to be off. The circuit shown here is eminently suitable for this application. The circuit is placed near the rear fog light of the car. The 12-V connection to the lamp has to be interrupted and is instead connected to relay contacts 30 and 87A (K1, K3). When the rear fog light is turned on it will continue to operate normally. If a trailer with fog light is now connected to the trailer connector (7- or 13-way, K2), a current will flow through L1.

L1 is a coil with about 8 turns, wound around reed contact S1. S1 will close because of the current through L1, which in turn energizes relay Re1 and the rear fog light of the car is switched off. The fog light of the trailer is on, obviously. The size of L1 depends on reed contact S1. The fog lamp is 21 W, so at 12 V there is a current of 1. 75 A. L1 is sized for a current between 1. 0 and 1. 5 A, so that it is certain that the contact closes. The wire size has to be about 0. 8 mm. The relay Re1 is an automotive relay that is capable of switching the lamp current. The voltage drop across L1 is negligible. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713